Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printing Pressman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

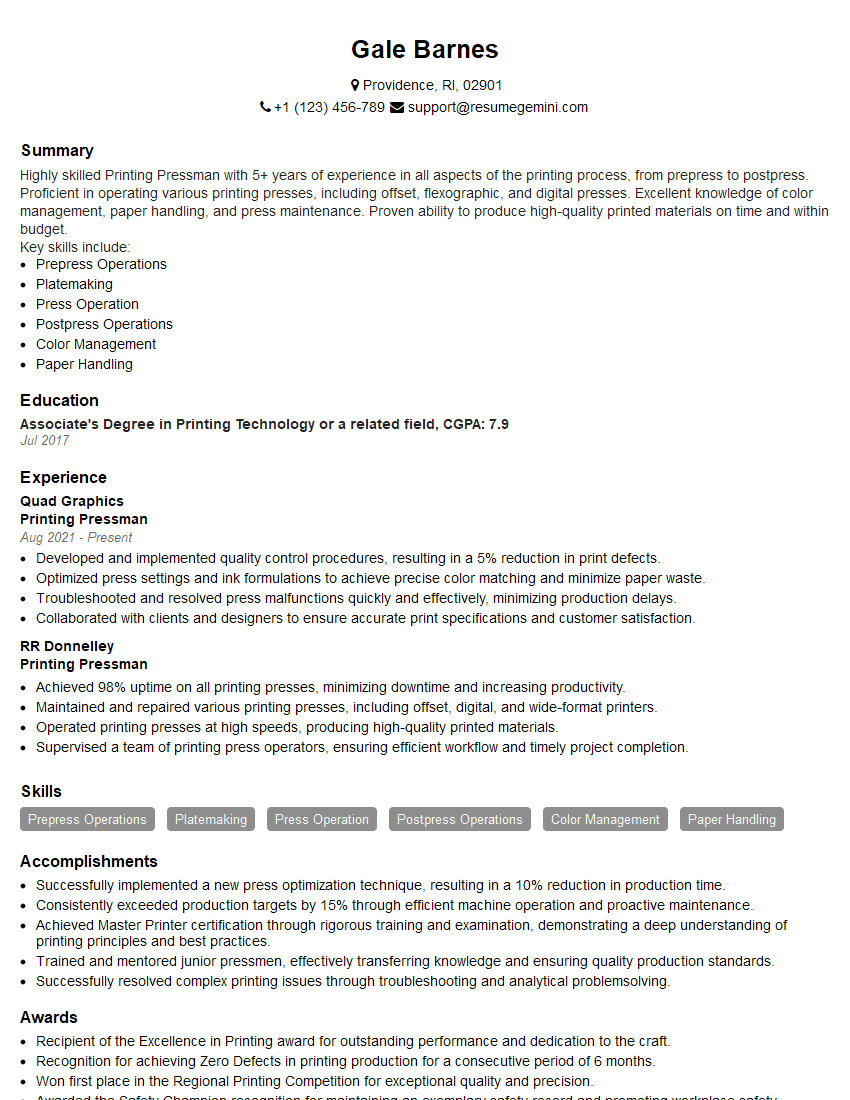

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printing Pressman

1. How do you determine the correct ink viscosity for a specific printing job?

To ensure optimal print quality and minimize press issues, determining the correct ink viscosity is crucial. I utilize various methods:

- Viscometer measurement: I use a viscometer to measure the ink’s viscosity and compare it to the manufacturer’s specifications.

- Ink drawdown test: I perform a drawdown test to assess the ink’s flow and leveling properties on a specific substrate.

- Press trial: In certain situations, I conduct a small press trial to evaluate the ink’s performance on the printing press and make necessary adjustments.

2. Describe the process of makeready for a printing press.

Prepress:

- Plate inspection: I thoroughly inspect the printing plates for any defects or damage.

- Plate mounting: I carefully mount the plates onto the press cylinders, ensuring proper alignment and registration.

On press:

- Impression and register settings: I adjust the impression and register to achieve optimal print quality and alignment.

- Ink and water balance: I fine-tune the ink and water balance to optimize ink transfer and prevent ghosting or set-off.

- Test prints and adjustments: I run test prints and make necessary adjustments to the press settings until the desired print quality is achieved.

3. How do you troubleshoot and resolve common printing problems, such as misregistration or color variations?

Troubleshooting and resolving printing problems requires a systematic approach:

- Identify the issue: I carefully examine the printed samples to identify the specific problem, such as misregistration or color variations.

- Determine the cause: I analyze potential causes, such as press settings, plate issues, ink properties, or substrate characteristics.

- Implement solutions: Based on the identified cause, I implement corrective measures, such as adjusting registration, replacing plates, optimizing ink viscosity, or changing the substrate.

- Monitor and evaluate: I monitor the printing process and evaluate the effectiveness of the implemented solutions, making further adjustments as needed.

4. Describe your experience in printing on different types of substrates, such as coated paper, uncoated paper, and specialty media.

I have extensive experience in printing on various substrates, including:

- Coated paper: I understand the importance of ink absorption and surface smoothness for achieving high-quality prints on coated paper.

- Uncoated paper: I possess expertise in optimizing ink penetration and drying time to ensure proper print adhesion on uncoated paper.

- Specialty media: I have experience in handling specialty substrates, such as plastics, films, and metal, requiring specialized printing techniques and considerations.

5. How do you ensure consistent print quality throughout a long print run?

Maintaining consistent print quality during long print runs is crucial:

- Monitor ink and water levels: I regularly check and adjust ink and water levels to maintain optimal ink transfer and prevent variations.

- Control press settings: I ensure that press settings, such as impression and register, are consistent throughout the run.

- Regular press maintenance: I perform preventive maintenance tasks, such as cleaning rollers and blankets, to minimize potential quality issues.

- Plate inspection: I periodically inspect the printing plates for wear or damage, replacing them as necessary.

6. Describe your knowledge of different printing processes, such as offset lithography, flexography, and digital printing.

I am familiar with various printing processes, including:

- Offset lithography: I understand the principles of image transfer from a metal plate to a rubber blanket and then to paper.

- Flexography: I have experience in using flexible printing plates and solvent-based inks for packaging and label printing.

- Digital printing: I am proficient in operating digital presses that utilize toner-based or inkjet technologies.

7. How do you stay up-to-date with the latest printing technologies and industry best practices?

To stay current with advancements in the printing industry:

- Attend industry events: I regularly participate in conferences, trade shows, and workshops to learn about new technologies and trends.

- Read industry publications: I subscribe to printing magazines and online resources to stay informed about industry news and best practices.

- Collaborate with peers: I engage in discussions with colleagues and industry professionals to exchange knowledge and ideas.

8. How do you prioritize tasks and manage your time effectively in a fast-paced printing environment?

Prioritizing tasks and managing time efficiently is essential in a fast-paced printing environment:

- Prioritize based on deadlines: I prioritize tasks based on their due dates and the impact on overall production.

- Break down large tasks: I decompose complex tasks into smaller, manageable steps to enhance focus and efficiency.

- Utilize technology: I leverage project management software and other tools to streamline tasks and track progress.

9. How do you handle working independently and as part of a team in a printing press environment?

In a printing press environment, I am comfortable working both independently and as part of a team:

Independent work:

- Self-motivation: I am self-driven and can work independently, managing my tasks and responsibilities effectively.

Teamwork:

- Collaboration: I effectively collaborate with colleagues to achieve shared goals and resolve challenges.

- Communication: I maintain open communication, providing regular updates and seeking input from team members.

10. How do you ensure safety in the printing press environment?

Safety is paramount in a printing press environment:

- Follow safety protocols: I adhere to established safety guidelines, including wearing appropriate PPE and operating machinery correctly.

- Identify hazards: I am proactive in identifying potential hazards and taking steps to mitigate risks.

- Stay alert: I maintain a high level of alertness, paying attention to surroundings and potential hazards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printing Pressman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printing Pressman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printing Pressmen are responsible for operating and maintaining printing presses to produce high-quality printed materials.

1. Preparation

Preparing the printing press for production, including loading paper, setting up ink fountains, and adjusting printing plates.

- Verifying that all materials are present and correct

- Performing regular maintenance checks on equipment

2. Operation

Operating the printing press to produce printed materials, monitoring the press during operation, and making adjustments as needed.

- Ensuring that the press is operating at optimal speed and efficiency

- Identifying and correcting any printing defects

3. Maintenance

Performing basic maintenance and repairs on the printing press, cleaning the press and equipment, and following safety procedures.

- Lubricating moving parts

- Inspecting equipment for wear and damage

4. Quality Control

Inspecting printed materials for quality, ensuring that they meet customer specifications, and making adjustments as needed.

- Verifying that colors are accurate

- Checking for registration and sharpness

Interview Tips

Preparing for a Printing Pressman interview can be stressful, but following these tips can help you present yourself as the best candidate.

1. Research the Company and the Position

Take the time to learn about the company’s history, culture, and products or services. This will help you understand the company’s needs and how your skills and experience can contribute to their success.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on the latest trends and technologies

2. Prepare for Common Interview Questions

Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- Highlight your skills and experience that are relevant to the position

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments

3. Be Prepared to Talk About Your Experience

Be prepared to discuss your experience in detail, including your responsibilities, accomplishments, and how your skills and knowledge can benefit the company.

- Quantify your accomplishments whenever possible

- Use examples to demonstrate your skills and abilities

4. Ask Questions

Asking well-thought-out questions shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture and values

- Inquire about the company’s plans for growth and expansion

Next Step:

Now that you’re armed with the knowledge of Printing Pressman interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Printing Pressman positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini