Are you gearing up for an interview for a Process Chemist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Process Chemist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

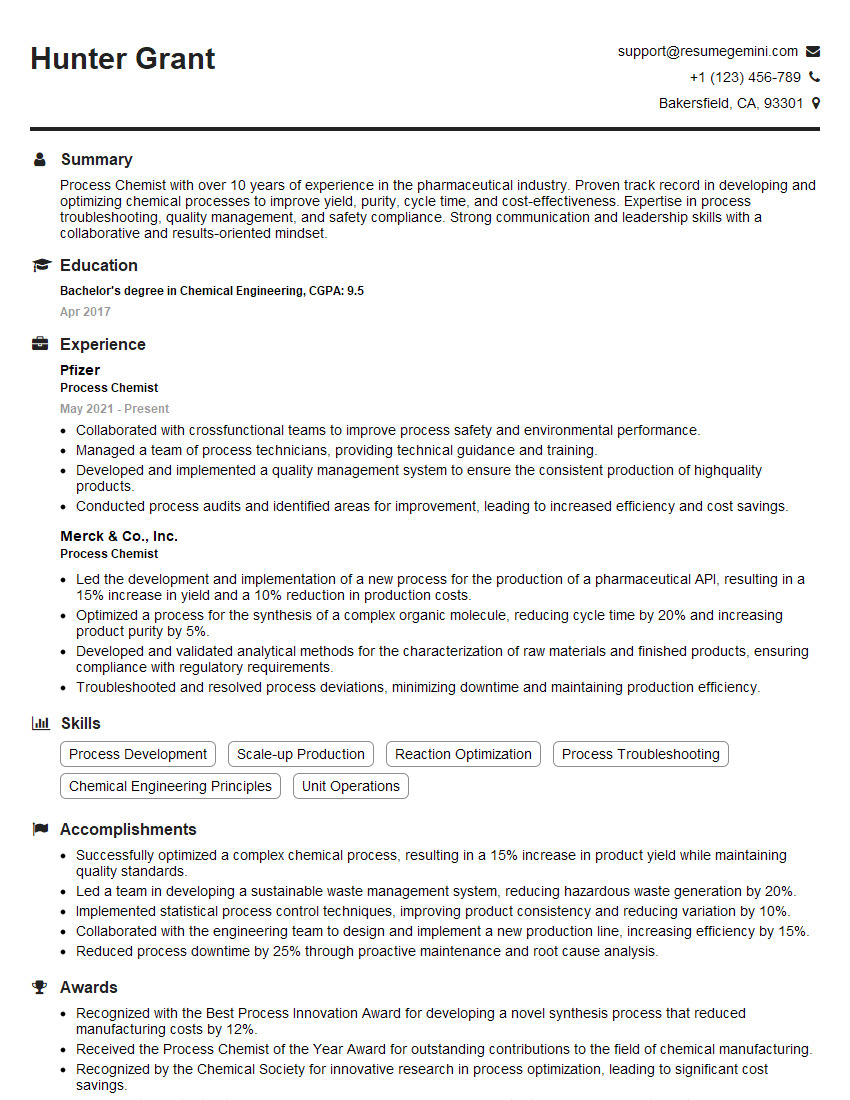

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Process Chemist

1. What are the key responsibilities of a Process Chemist?

The key responsibilities of a Process Chemist typically include:

- Developing and optimizing chemical processes for the production of various products

- Conducting experiments to validate process parameters and determine optimal operating conditions

- Analyzing and evaluating data to identify areas for improvement in process efficiency and yield

- Collaborating with other departments, such as Engineering and Production, to ensure smooth implementation of chemical processes

- Maintaining up-to-date knowledge of industry best practices and regulatory compliance

2. Describe your experience in developing and optimizing chemical processes.

Experience in Process Development

- Conducted extensive research and experimentation to identify suitable chemical reactions and catalysts

- Evaluated process parameters such as temperature, pressure, and reaction time to optimize yield and efficiency

- Successfully scaled up laboratory-scale processes to pilot and commercial production levels

Experience in Process Optimization

- Analyzed process data to identify bottlenecks and areas for improvement

- Implemented process modifications, such as adjusting reaction conditions or introducing new catalysts, to enhance productivity

- Collaborated with production engineers to implement optimized processes and achieve operational excellence

3. How do you approach troubleshooting process-related issues?

When troubleshooting process-related issues, I follow a systematic approach that typically involves:

- Gathering data and analyzing process parameters to identify deviations

- Reviewing operating logs and maintenance records to pinpoint potential causes

- Conducting experiments or simulations to test hypotheses and validate solutions

- Implementing corrective actions and monitoring the process to ensure the issue is resolved

4. What analytical techniques are you familiar with, and how do you use them in process development and optimization?

I am proficient in various analytical techniques commonly used in process development and optimization, including:

- Chromatography (HPLC, GC)

- Spectroscopy (UV-Vis, IR, NMR)

- Mass Spectrometry (MS)

- Thermal analysis (DSC, TGA)

I utilize these techniques to:

- Identify and quantify reactants, intermediates, and products

- Monitor process reactions and determine conversion rates

- Characterize materials and investigate their properties

- Troubleshoot process issues and identify root causes

5. How do you ensure the quality and consistency of chemical processes?

To ensure the quality and consistency of chemical processes, I implement the following measures:

- Establishing and maintaining quality control standards and procedures

- Regularly monitoring process parameters and conducting quality checks

- Validating processes and equipment to ensure compliance with specifications

- Implementing statistical process control techniques to minimize variability and improve predictability

- Continuously evaluating and improving processes to enhance efficiency and meet customer requirements

6. What experience do you have in working with different types of reactors?

I have experience working with various types of reactors, including:

- Batch reactors

- Continuous stirred-tank reactors (CSTRs)

- Plug flow reactors

- Fluidized bed reactors

- Packed bed reactors

For each type of reactor, I have gained expertise in:

- Design and scale-up considerations

- Optimization of operating parameters

- Troubleshooting and maintenance procedures

7. How do you handle scale-up challenges when moving from lab-scale processes to commercial production?

When scaling up processes from lab-scale to commercial production, I address the following challenges:

- Heat and mass transfer limitations

- Mixing and agitation requirements

- Reactor design and selection

- Process control and optimization

- Material handling and logistics

To overcome these challenges, I employ a combination of approaches, including:

- Modeling and simulation to predict process behavior at different scales

- Pilot-scale testing to validate process parameters and identify potential issues

- Collaboration with engineers and production teams to ensure smooth implementation

8. What are your strengths and weaknesses as a Process Chemist?

Strengths

- Strong analytical and problem-solving skills

- Expertise in process development, optimization, and troubleshooting

- Experience in various analytical techniques

- Ability to work independently and as part of a team

- Excellent communication and presentation skills

Weaknesses

- Limited experience in certain specialized areas of process chemistry

- Can sometimes be too detail-oriented, which may slow down progress

9. How do you stay up-to-date with the latest advancements in process chemistry?

To stay up-to-date with the latest advancements in process chemistry, I engage in the following activities:

- Attending conferences and workshops

- Reading scientific journals and industry publications

- Participating in online forums and discussion groups

- Collaborating with researchers and experts in the field

- Conducting research and development projects

10. What are your career goals and how do you see this role contributing to your professional development?

My career goal is to become a leading Process Chemist, specializing in the development and optimization of sustainable and efficient chemical processes. I believe that this role will provide me with the opportunity to:

- Expand my knowledge and expertise in process chemistry

- Contribute to the development of innovative and environmentally friendly processes

- Work with a team of talented professionals and learn from experienced mentors

- Make a positive impact on the industry and society as a whole

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Process Chemist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Process Chemist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Process Chemists play a critical role in the development and optimization of chemical processes in various industries, ensuring efficient and cost-effective production. Their key responsibilities include:

1. Process Development and Optimization

Design and conduct experiments to develop and optimize chemical processes, evaluating process parameters, reaction conditions, and equipment performance.

- Develop and implement strategies to improve process efficiency, yield, and quality.

- Troubleshoot and resolve process issues, identifying and addressing root causes.

2. Analytical Characterization

Conduct analytical tests and evaluations to characterize raw materials, intermediates, and final products.

- Interpret and analyze data to identify process improvements and ensure product quality.

- Develop and validate analytical methods to support process development and control.

3. Process Scale-Up and Implementation

Collaborate with engineering teams to scale-up laboratory-scale processes to pilot and production plants.

- Manage the transfer of technology from research and development to manufacturing.

- Provide technical support and guidance during process implementation and troubleshooting.

4. Regulatory Compliance

Ensure compliance with environmental, health, and safety regulations and industry standards.

- Conduct risk assessments and develop mitigation plans to minimize potential hazards.

- Train and mentor staff on proper chemical handling and safety protocols.

Interview Tips

Preparing thoroughly for a Process Chemist interview is essential to showcase your skills and knowledge. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research the specific role you are applying for and identify the key responsibilities.

- Visit the company’s website and read industry publications to gain insights.

- Connect with current or former employees on LinkedIn to get an insider’s perspective.

2. Highlight Your Technical Skills

Emphasize your expertise in process development, analytical characterization, and scale-up. Quantify your accomplishments and provide specific examples of your contributions.

- Discuss projects where you improved process efficiency or product quality.

- Share your experience in developing and validating analytical methods.

- Describe your involvement in the scale-up of laboratory processes to production.

3. Showcase Your Problem-Solving Abilities

Process Chemists often face challenges in process development and optimization. Highlight your ability to identify and solve problems effectively.

- Provide examples of troubleshooting and resolving process issues.

- Explain how you approach and analyze data to identify root causes.

- Discuss your experience in implementing solutions and evaluating their impact.

4. Emphasize Your Communication and Teamwork Skills

Process Chemists work closely with engineers, technicians, and other team members. Demonstrate your ability to communicate complex technical information clearly.

- Give examples of effective presentations you have delivered to technical audiences.

- Describe your experience in working collaboratively on interdisciplinary teams.

- Highlight your ability to build relationships and foster a positive work environment.

5. Practice Interview Questions

Prepare for common interview questions by practicing your answers aloud. This will help you articulate your skills and experiences confidently.

- Review common questions about process chemistry, analytical techniques, and problem-solving.

- Ask a friend or mentor to conduct a mock interview and provide feedback.

- Practice answering situational questions by describing specific examples from your work experience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Process Chemist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!