Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Process Control Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

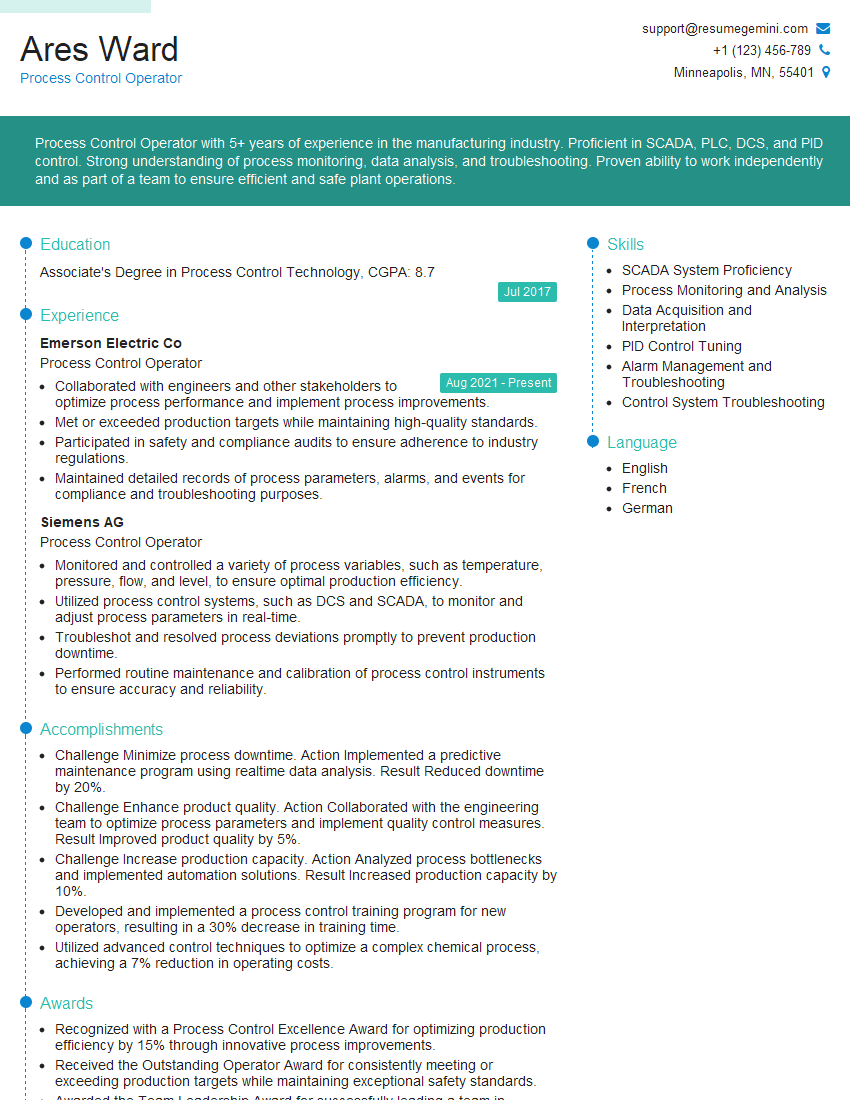

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Process Control Operator

1. Explain the concept of feedback control loop and how it is used in process control?

In a feedback control loop, the output of a process is measured and compared to a desired setpoint. The difference between the measured output and the setpoint is called the error. The error is then used to adjust the input to the process in a way that reduces the error.

- Feedback control loops are used in a wide variety of process control applications, such as temperature control, pressure control, and flow control.

- The main benefit of using a feedback control loop is that it helps to maintain a consistent output, even in the presence of disturbances.

2. What are the different types of control valves and how are they used in process control?

Control Valve Types

- Globe valves

- Gate valves

- Ball valves

- Butterfly valves

- Diaphragm valves

Control Valve Uses

- Globe valves are used for throttling applications, where precise flow control is required.

- Gate valves are used for on/off applications, such as isolating a section of pipe.

- Ball valves are also used for on/off applications, and they are often used in high-pressure applications.

- Butterfly valves are used for throttling applications, and they are often used in large-diameter pipes.

- Diaphragm valves are used for throttling applications, and they are often used in applications where there is a need for leak-tight shutoff.

3. What is the difference between open-loop and closed-loop control systems?

In an open-loop control system, the output of the process is not measured and fed back to the controller. This means that the controller does not have any information about the actual output of the process, and it can only make decisions based on the input.

In a closed-loop control system, the output of the process is measured and fed back to the controller. This means that the controller has information about the actual output of the process, and it can use this information to make decisions about how to adjust the input.

- Closed-loop control systems are more accurate and reliable than open-loop control systems.

- Closed-loop control systems are also more robust, meaning that they are less likely to be affected by disturbances.

4. What is the purpose of a PID controller?

A PID controller is a type of feedback controller that is used to control the output of a process. The PID controller uses three terms to calculate the error signal: the proportional term, the integral term, and the derivative term.

- The proportional term is used to reduce the error quickly.

- The integral term is used to eliminate the steady-state error.

- The derivative term is used to anticipate changes in the error and to reduce overshoot.

5. What are the different types of process disturbances?

- Load disturbances

- Parameter disturbances

- Measurement disturbances

Load disturbances are caused by changes in the input to the process. Parameter disturbances are caused by changes in the process parameters. Measurement disturbances are caused by changes in the measurement of the process output.

6. What are the different methods of process control?

- Manual control

- Automatic control

- Computer control

Manual control is the most basic type of process control, and it involves the operator manually adjusting the process inputs based on the output measurements.

Automatic control is a more advanced type of process control, and it involves the use of controllers to automatically adjust the process inputs based on the output measurements.

Computer control is the most advanced type of process control, and it involves the use of computers to monitor and control the process.

7. What are the benefits of using a distributed control system (DCS)?

- Improved reliability

- Increased flexibility

- Reduced costs

- Improved safety

DCSs are becoming increasingly popular in the process control industry due to their many benefits.

8. What are the different types of process control software?

- SCADA systems

- Historian systems

- Simulation software

- Optimization software

Each type of software has its own specific purpose, and it is important to choose the right software for the job.

9. What are the different types of process control hardware?

- Controllers

- Sensors

- Actuators

- Networks

Each type of hardware has its own specific purpose, and it is important to choose the right hardware for the job.

10. What are the different types of process control applications?

- Temperature control

- Pressure control

- Flow control

- Level control

Each type of application has its own specific requirements, and it is important to choose the right control strategy for the job.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Process Control Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Process Control Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Process Control Operators play a crucial role in industrial facilities, ensuring the smooth and efficient operation of complex manufacturing processes. Their responsibilities encompass a wide range of tasks related to process monitoring, control, and optimization.

1. Monitor and Control Process Parameters

Process Control Operators monitor and adjust critical process parameters, such as temperature, pressure, flow rate, and chemical composition, to maintain optimal production conditions.

- Analyze process data and identify deviations from desired values

- Operate control systems to make necessary adjustments

2. Maintain Process Equipment

Operators perform routine maintenance and troubleshooting tasks to ensure the proper functioning of process equipment.

- Inspect and calibrate instruments

- Perform preventive maintenance procedures

3. Troubleshoot and Resolve Process Issues

When process deviations or malfunctions occur, Operators troubleshoot and identify the root cause.

- Analyze alarm conditions

- Implement corrective actions

4. Optimize Process Efficiency

Operators continuously seek opportunities to improve process efficiency and productivity.

- Identify and eliminate process bottlenecks

- Implement process optimization strategies

Interview Preparation Tips

To ace an interview for a Process Control Operator position, candidates should be well-prepared and familiar with the key responsibilities and requirements of the role. Here are some tips to help prepare:

1. Research the Company and Role

Thoroughly research the company, its industry, and the specific position you’re applying for. By understanding the company’s operations and the role’s responsibilities, you can tailor your answers to demonstrate your knowledge.

2. Highlight Relevant Experience

In your resume and interview, emphasize your relevant skills and experience in process control. If you have previous experience as a Process Control Operator, quantify your accomplishments and provide specific examples of your work.

3. Practice Answering Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the interview. Focus on questions related to your technical skills, problem-solving abilities, and teamwork.

4. Prepare Technical Questions

At the end of the interview, show your interest in the role by asking well-thought-out technical questions about the process, equipment, or the company’s goals. This demonstrates your enthusiasm and eagerness to learn.

5. Dress Professionally and Be Punctual

First impressions matter. Dress professionally and arrive on time for your interview. Maintain a positive and respectful attitude throughout the interview process.

Next Step:

Now that you’re armed with the knowledge of Process Control Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Process Control Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini