Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Process Control Tech position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

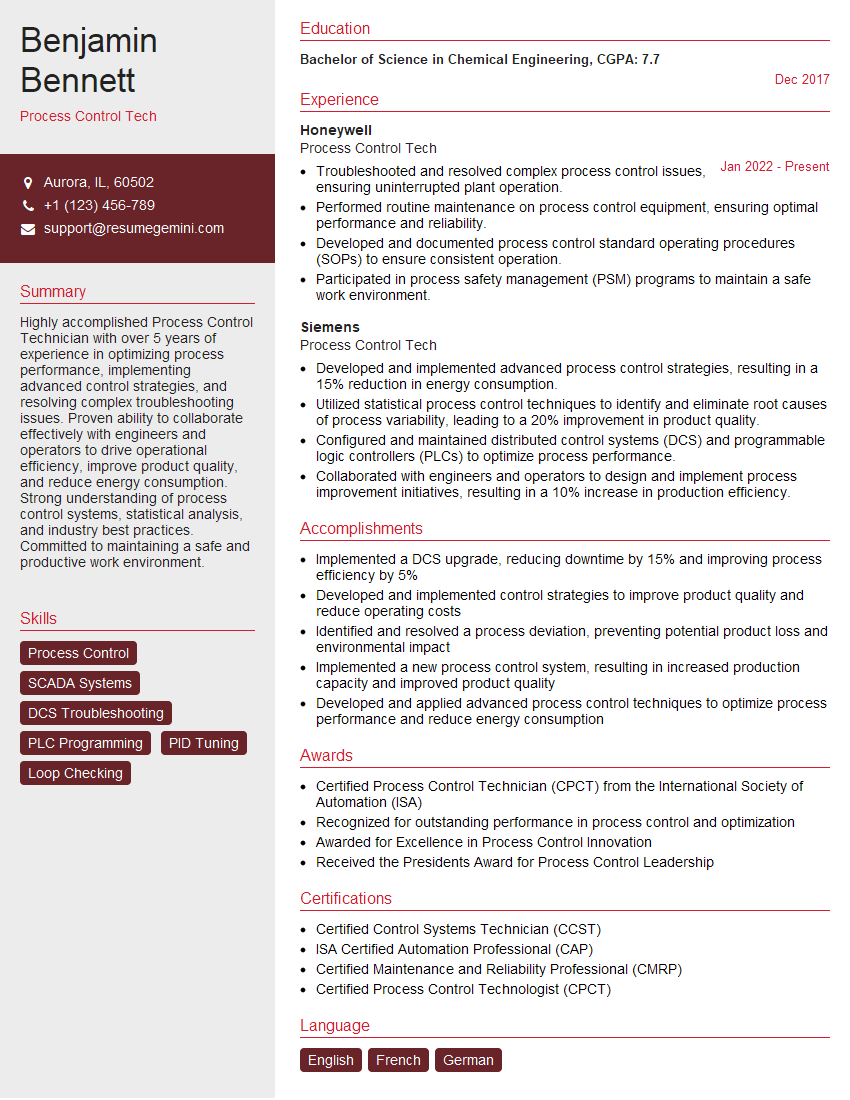

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Process Control Tech

1. What is the purpose of a PID controller and how does it work?

A PID controller is a control loop mechanism that uses a proportional-integral-derivative (PID) algorithm to regulate the output of a process.

- The proportional term (P) adjusts the output based on the error between the measured value and the desired setpoint.

- The integral term (I) reduces steady-state error by accumulating the error over time and adjusting the output accordingly.

- The derivative term (D) provides anticipatory control by responding to the rate of change of the error and adjusting the output to counteract future deviations.

2. Explain the difference between an open-loop and a closed-loop control system.

Open-loop Control System

- No feedback mechanism.

- Output is not compared to the desired setpoint.

- Suitable for simple processes with minimal disturbances.

Closed-loop Control System

- Feedback mechanism measures the output and compares it to the setpoint.

- Error signal is used to adjust the input to the process.

- Provides greater accuracy and stability in the face of disturbances.

3. What are the different types of process variables (PVs) and how are they measured?

- Temperature: Measured using thermocouples, resistance temperature detectors (RTDs), or infrared sensors.

- Pressure: Measured using pressure gauges, transducers, or differential pressure transmitters.

- Flow: Measured using flowmeters, such as orifice plates, venturi tubes, or ultrasonic flowmeters.

- Level: Measured using level gauges, displacers, or ultrasonic level transmitters.

4. What is the role of a programmable logic controller (PLC) in a process control system?

- Centralized control of multiple processes and devices.

- Handles logic operations, timing, and data acquisition.

- Provides a user-friendly interface for monitoring and controlling the process.

- Can communicate with other devices and systems via various communication protocols.

5. Describe the steps involved in tuning a PID controller.

- 1. Proportional Gain (Kp): Increase Kp gradually until the output oscillates, then reduce it to the point where oscillations cease.

- 2. Integral Gain (Ki): Increase Ki slowly while observing the settling time and overshoot. Adjust it until the desired response is achieved.

- 3. Derivative Gain (Kd): Use Kd sparingly to reduce overshoot. Increase Kd until the response becomes too oscillatory, then reduce it slightly.

6. What are some common troubleshooting techniques for process control systems?

- Check the sensors: Ensure they are calibrated and properly connected.

- Inspect the control valves: Check for proper operation, leaks, or debris.

- Verify the PLC program: Examine the logic and settings to identify any errors.

- Analyze the process data: Review historical trends and alarms to identify potential issues.

7. Can you describe the role of distributed control systems (DCSs) in complex process control applications?

- Centralized monitoring and control: DCSs provide a single interface for managing multiple processes and devices across a large plant.

- Data acquisition and processing: DCSs collect and analyze data from various sources to optimize process performance.

- Alarm and event management: DCSs monitor process variables and generate alarms to alert operators to potential issues.

- Networking and communication: DCSs connect to PLCs, field devices, and other systems to facilitate data exchange and control.

8. How do you approach the design of a process control system for a new plant?

- Define process requirements: Identify the desired control parameters, setpoints, and performance specifications.

- Select appropriate instrumentation: Choose sensors, transducers, and control valves based on the process needs and measurement accuracy.

- Design the control strategy: Determine the control algorithm, loop configuration, and PID tuning parameters.

- Implement and test the system: Install the hardware and software, configure the devices, and verify the system’s performance.

9. What are some emerging trends in process control technology?

- Artificial intelligence (AI): AI techniques are used for predictive maintenance, fault detection, and process optimization.

- Model-based control: Uses mathematical models of the process to improve control performance and predict future behavior.

- Wireless sensor networks: Provide real-time data collection and monitoring without the need for physical wiring.

- Cloud computing: Allows for remote access to process data, analytics, and control functions.

10. How do you stay up-to-date with the latest advancements in process control technology?

- Attend industry conferences and exhibitions: Network with experts and learn about new products and technologies.

- Read technical journals and publications: Stay informed about research and best practices in the field.

- Participate in online forums and discussions: Engage with peers and share knowledge on process control.

- Pursue continuing education and training: Take courses or workshops to enhance your skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Process Control Tech.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Process Control Tech‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Process Control Technicians are responsible for monitoring, controlling, and optimizing industrial processes. They use their knowledge of process control systems, instrumentation, and automation to ensure that processes run efficiently and safely.

1. Monitor and Control Process Parameters

Process Control Technicians are responsible for monitoring and controlling a variety of process parameters, such as temperature, pressure, flow rate, and product quality. They use a variety of instruments and sensors to collect data on these parameters and make adjustments to the process as needed to keep it within desired ranges.

2. Troubleshoot and Resolve Process Issues

Process Control Technicians are also responsible for troubleshooting and resolving process issues. They use their knowledge of process control systems and instrumentation to identify the root cause of problems and develop solutions. They may also work with other technicians or engineers to repair or replace equipment.

3. Optimize Process Performance

Process Control Technicians are also responsible for optimizing process performance. They use a variety of techniques to improve efficiency, reduce costs, and increase product quality. They may also work with other departments to develop and implement new process control strategies.

4. Ensure Process Safety

Process Control Technicians are responsible for ensuring process safety. They use their knowledge of process control systems and instrumentation to identify potential hazards and develop safety procedures. They also train other employees on process safety procedures and respond to emergencies.

Interview Tips

Preparing for a Process Control Tech interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you prepare:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture, goals, and needs. You should also review the job description carefully and identify the key skills and qualifications that the company is looking for.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the position you’re applying for. Use specific examples to demonstrate your abilities and how you’ve used them to achieve success in your previous roles.

4. Be Prepared to Talk About Your Knowledge of Process Control

Interviewers will want to know about your knowledge of process control, so be prepared to talk about your experience with process control systems, instrumentation, and automation. You should also be able to discuss your understanding of process safety and how you’ve ensured safety in your previous roles.

5. Ask Questions

At the end of your interview, be sure to ask the interviewer questions about the position and the company. This shows that you’re interested in the opportunity and that you’re taking the interview seriously.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Process Control Tech, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Process Control Tech positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.