Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Process Design Chemical Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Process Design Chemical Engineer so you can tailor your answers to impress potential employers.

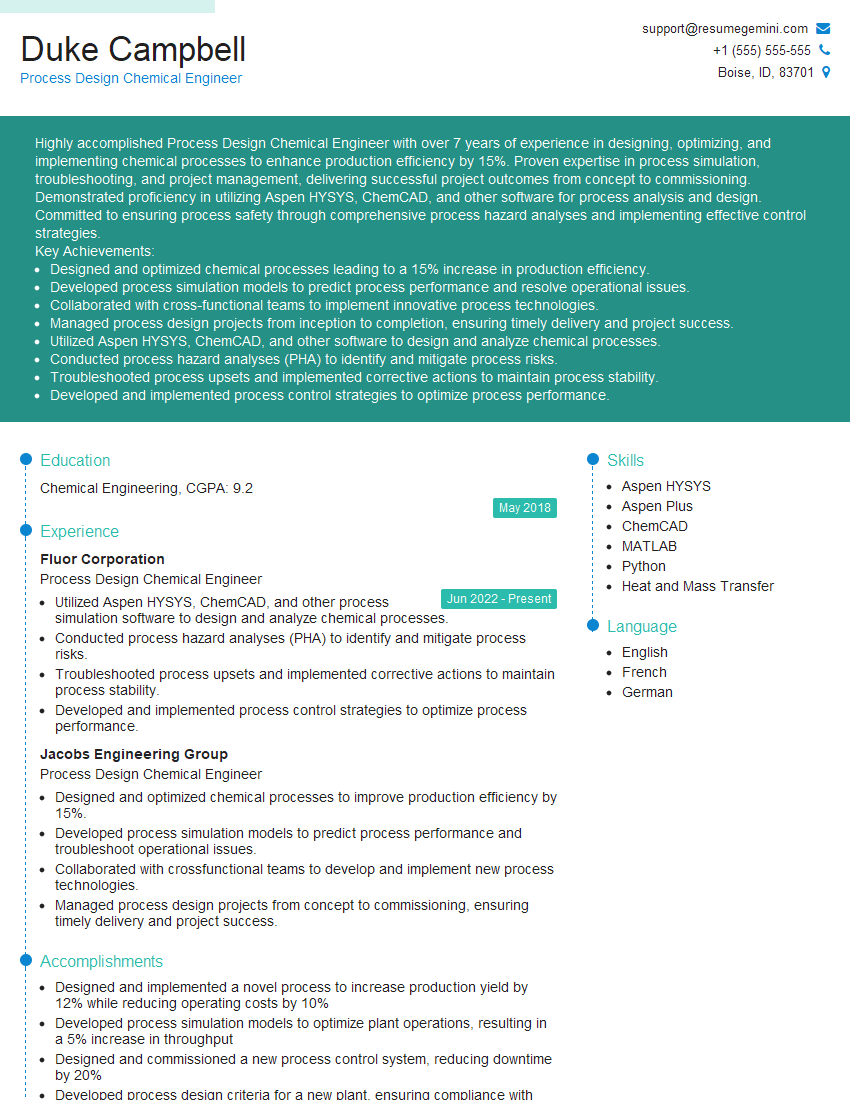

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Process Design Chemical Engineer

1. How do you approach the design of a chemical process from scratch?

- Define the problem statement and objectives.

- Gather data on the raw materials, products, and process conditions.

- Develop a conceptual process flow diagram.

- Select and size the equipment.

- Develop a detailed process flow diagram and piping and instrumentation diagram.

- Estimate the capital and operating costs.

- Optimize the process design.

2. What are the key considerations in designing a chemical reactor?

subheading of the answer

- Type of chemical reaction

- Reaction kinetics

- Heat and mass transfer

- Safety and environmental considerations

subheading of the answer

- Reactor type

- Reactor size

- Materials of construction

- Operating conditions

3. What are the different types of heat exchangers and how do you select the best one for a given application?

- Type of heat exchanger

- Materials of construction

- Heat transfer rate

- Pressure drop

- Cost

4. What are the key considerations in designing a distillation column?

- Number of stages

- Reflux ratio

- Boiler and condenser design

- Materials of construction

- Operating conditions

5. What are the different types of process control systems and how do you select the best one for a given application?

- Type of process control system

- Control objectives

- Control strategy

- Cost

6. What are the key considerations in designing a piping system?

- Type of fluid

- Flow rate

- Pressure

- Temperature

- Materials of construction

7. What are the different types of pumps and how do you select the best one for a given application?

- Type of pump

- Capacity

- Head

- Efficiency

- Cost

8. What are the key considerations in designing a storage tank?

- Type of fluid

- Storage capacity

- Materials of construction

- Operating conditions

- Safety and environmental considerations

9. What are the different types of process safety systems and how do you select the best one for a given application?

- Type of process safety system

- Safety objectives

- Control strategy

- Cost

10. What are the key considerations in designing a plant layout?

- Process flow

- Equipment size and location

- Materials handling

- Safety and environmental considerations

- Cost

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Process Design Chemical Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Process Design Chemical Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Process Design Chemical Engineer

Process Design Chemical Engineers play a crucial role in the design, development, and optimization of chemical processes. Their key responsibilities include:1. Process Design and Development

Designing and developing new or improved chemical processes that meet specific production requirements and optimize efficiency.

- Conducting feasibility studies, process simulations, and economic evaluations.

- Developing process flow diagrams, piping and instrumentation diagrams, and other engineering drawings.

2. Process Evaluation and Optimization

Evaluating existing processes to identify areas for improvement and optimizing them to enhance efficiency, productivity, and safety.

- Analyzing process data, identifying bottlenecks, and recommending solutions.

- Implementing process modifications, upgrades, and new technologies to improve performance.

3. Equipment Selection and Specification

Selecting and specifying equipment, such as reactors, vessels, pumps, and heat exchangers, to meet process requirements.

- Evaluating vendor proposals, conducting site visits, and recommending equipment suppliers.

- Developing specifications, design criteria, and performance guarantees for equipment.

4. Process Control and Automation

Designing and implementing process control systems to ensure stable and efficient operation of chemical processes.

- Selecting and configuring process instrumentation, controllers, and software.

- Developing automation strategies, sequence of operations, and safety interlocks.

5. Troubleshooting and Problem Solving

Identifying and resolving process issues, ensuring smooth and efficient plant operations.

- Performing root cause analysis, recommending corrective actions, and monitoring their implementation.

- Working with plant operators to troubleshoot and resolve process problems.

6. Regulatory Compliance and Environmental Management

Ensuring that process designs and operations comply with environmental regulations and safety standards.

- Conducting environmental impact assessments and developing mitigation strategies.

- Monitoring process emissions, wastewater discharge, and other environmental parameters.

Interview Preparation Tips for Process Design Chemical Engineers

To ace an interview for a Process Design Chemical Engineer position, it is important to prepare thoroughly and demonstrate your technical proficiency, problem-solving skills, and communication abilities. Here are some tips to help you prepare:1. Research the Company and Position

Thoroughly research the company, its industry, and the specific job requirements. This will help you understand the context of the role and tailor your answers accordingly.

2. Review Basic Chemical Engineering Concepts

Review fundamental principles of chemical engineering, including mass balances, energy balances, reaction kinetics, and fluid mechanics. Be prepared to discuss your understanding of these concepts and their application in process design.

3. Practice Problem Solving

Solve practice problems related to process design and optimization. This will demonstrate your analytical and problem-solving abilities and prepare you for technical questions you may encounter during the interview.

4. Prepare for Behavioral Questions

Prepare for common behavioral interview questions that focus on your teamwork, communication skills, and ability to handle challenges. Use the STAR method to structure your answers and provide specific examples of your experience.

5. Showcase Your Projects and Accomplishments

Highlight relevant projects and accomplishments that demonstrate your skills in process design, optimization, and troubleshooting. Quantify your results whenever possible to showcase your impact.

6. Practice Your Presentation Skills

Practice presenting your work clearly and concisely. You may be asked to present a process design or technical solution during the interview, so it is important to be confident and well-prepared.

7. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer about the company, the team, and the role. This shows your interest and enthusiasm for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Process Design Chemical Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!