Feeling lost in a sea of interview questions? Landed that dream interview for Process Plant Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Process Plant Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

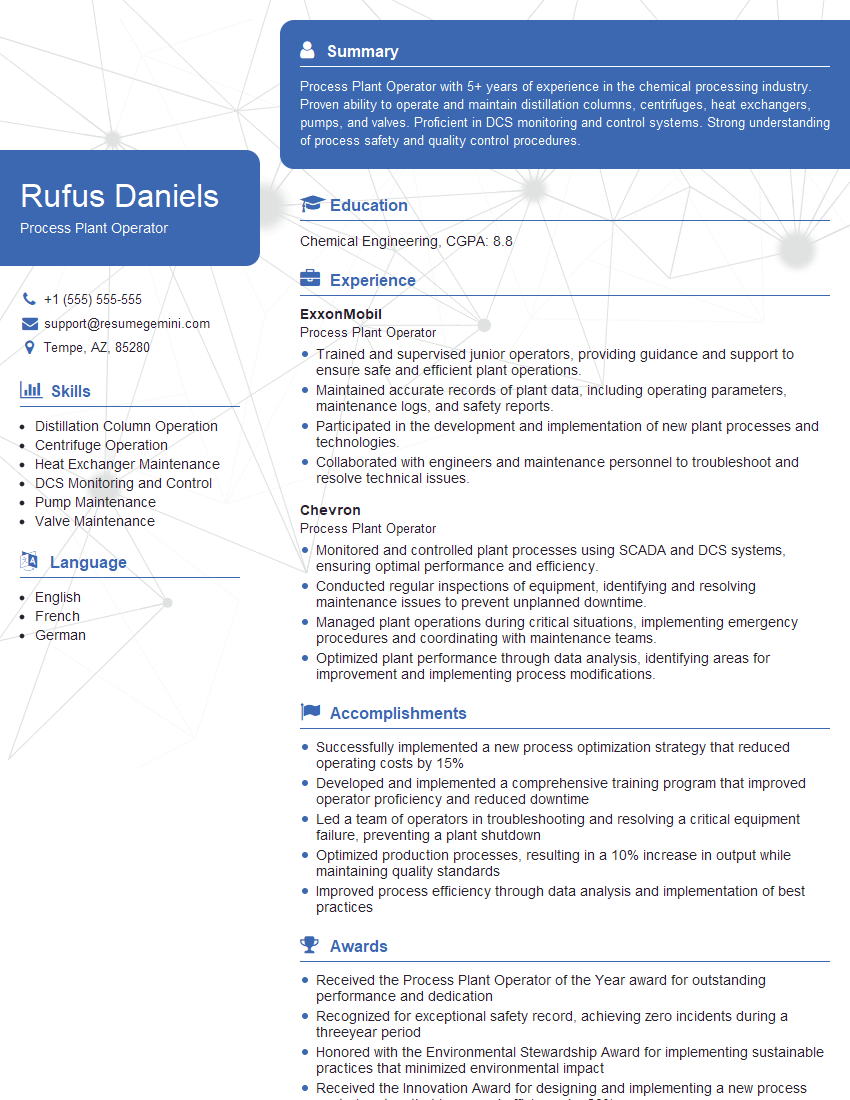

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Process Plant Operator

1. Explain the main responsibilities of a Process Plant Operator?

As a Process Plant Operator, my key responsibilities include:

- Monitoring and controlling process parameters to ensure optimal production levels.

- Performing routine maintenance and troubleshooting to maintain equipment efficiency.

- Ensuring compliance with safety protocols and industry standards.

- Gathering and analyzing data to identify areas for process improvement.

- Collaborating effectively with plant personnel in maintaining a safe and productive work environment.

2. Describe your experience in operating a specific type of process plant?

Batch Process

- Experience in operating batch processes involving raw material preparation, mixing, reaction, and packaging.

- Expertise in controlling critical process variables such as temperature, pressure, and batch size.

Continuous Process

- Proficient in managing continuous processes involving raw material feed, reaction, separation, and product finishing.

- Experience in controlling process flow rates, temperature profiles, and product quality.

3. How do you handle process deviations and emergency situations?

When faced with process deviations, I follow a structured approach:

- Quickly assess the situation and identify the root cause of the deviation.

- Take immediate corrective actions to stabilize the process and minimize downtime.

- Communicate clearly with supervisors and maintain accurate records of the incident.

- In emergency situations, I prioritize the safety of personnel and equipment. I activate the emergency response plan, isolate the affected area, and mitigate any potential hazards.

4. What are the different types of instruments used in process plants and how do you use them?

- Pressure gauges to monitor pressure levels in pipes, vessels, and tanks.

- Temperature sensors to measure process temperatures and maintain set points.

- Flowmeters to determine the rate of flow in pipes and lines.

- Level transmitters to monitor liquid or solid levels in tanks, silos, and vessels.

- Analyzers to test and monitor the composition of process streams.

- Controllers to regulate process variables based on desired set points.

5. Describe your understanding of process control systems (e.g., DCS, PLC)?

- DCS (Distributed Control System): Experience in operating DCS systems such as ABB Symphony Plus, Honeywell Experion PKS, or Siemens PCS 7. Proficiency in navigating the HMI (Human-Machine Interface) and managing process parameters.

- PLC (Programmable Logic Controller): Expertise in programming PLCs using languages like Ladder Logic, Function Block Diagram, or Structured Text. Experience in troubleshooting and maintaining PLC-based automation systems.

6. What are the essential safety protocols and industry standards applicable to process plant operations?

- OSHA (Occupational Safety and Health Administration) regulations

- EPA (Environmental Protection Agency) environmental standards

- ANSI/ISA (American National Standards Institute/International Society of Automation) codes and practices

- NFPA (National Fire Protection Association) standards

- Comply with specific plant safety policies and procedures

7. What is your approach to maintaining and troubleshooting plant equipment?

- Follow prescribed maintenance schedules and perform regular inspections.

- Use diagnostic tools and techniques to identify potential issues.

- Troubleshoot and rectify equipment malfunctions efficiently.

- Maintain detailed maintenance records and document repair work.

- Collaborate with maintenance technicians when necessary for major repairs or upgrades.

8. How do you ensure the quality and consistency of products in a process plant?

- Monitor process parameters closely and make adjustments as needed.

- Conduct regular quality checks and tests on raw materials, in-process products, and finished goods.

- Implement statistical process control (SPC) techniques to analyze and improve product quality.

- Follow established quality assurance procedures and standards.

- Work with quality control personnel to identify and resolve quality issues.

9. What is your understanding of process optimization techniques?

- Six Sigma methodologies to identify and eliminate waste and improve efficiency.

- Lean manufacturing principles to streamline processes and reduce downtime.

- Data analysis techniques to analyze process data and identify areas for improvement.

- Use of simulation software to model and optimize process operations.

- Participate in continuous improvement initiatives to enhance overall plant performance.

10. How do you effectively collaborate with other team members in a process plant environment?

- Communicate clearly and effectively with operators, supervisors, and maintenance personnel.

- Participate actively in team meetings and share information.

- Assist colleagues with troubleshooting and resolving process issues.

- Maintain a positive and cooperative work atmosphere.

- Support the team’s goals and objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Process Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Process Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Process Plant Operator is responsible for the safe and efficient operation of a process plant. Their key job responsibilities include:

1. Operating and monitoring process equipment

This involves starting, stopping, and adjusting equipment to ensure that it is operating within specified parameters. Process Plant Operators also monitor the equipment for any signs of problems and take corrective action as needed.

- Starting, stopping, and adjusting process equipment

- Monitoring equipment for any signs of problems

- Taking corrective action as needed

2. Maintaining process equipment

This involves performing routine maintenance tasks, such as cleaning, lubricating, and inspecting equipment. Process Plant Operators also troubleshoot and repair equipment as needed.

- Performing routine maintenance tasks

- Troubleshooting and repairing equipment

3. Monitoring process variables

This involves monitoring process variables, such as temperature, pressure, and flow rate, to ensure that they are within specified limits. Process Plant Operators also take corrective action as needed to adjust the process variables.

- Monitoring process variables

- Taking corrective action as needed

4. Recording process data

This involves recording process data, such as operating conditions and production rates, in a logbook or other record-keeping system. Process Plant Operators also prepare reports on the operation of the plant.

- Recording process data

- Preparing reports on the operation of the plant

Interview Tips

To ace an interview for a Process Plant Operator position, it is important to be prepared. Here are some tips:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to better understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

2. Prepare answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to prepare answers to these questions in advance so that you can deliver them confidently and concisely.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with process plant operation?

- How do you handle stress and pressure?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience with process plant operation. Be prepared to talk about your experience in detail, including the specific tasks you have performed and the equipment you have operated.

- Talk about your experience with process plant operation

- Discuss the specific tasks you have performed

- Describe the equipment you have operated

4. Be prepared to answer technical questions

The interviewer may also ask you some technical questions about process plant operation. Be prepared to answer these questions to the best of your ability, even if you do not know the answer to every question.

- Be prepared to answer technical questions

- Answer the questions to the best of your ability

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Process Plant Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.