Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Processes Chemical Design Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

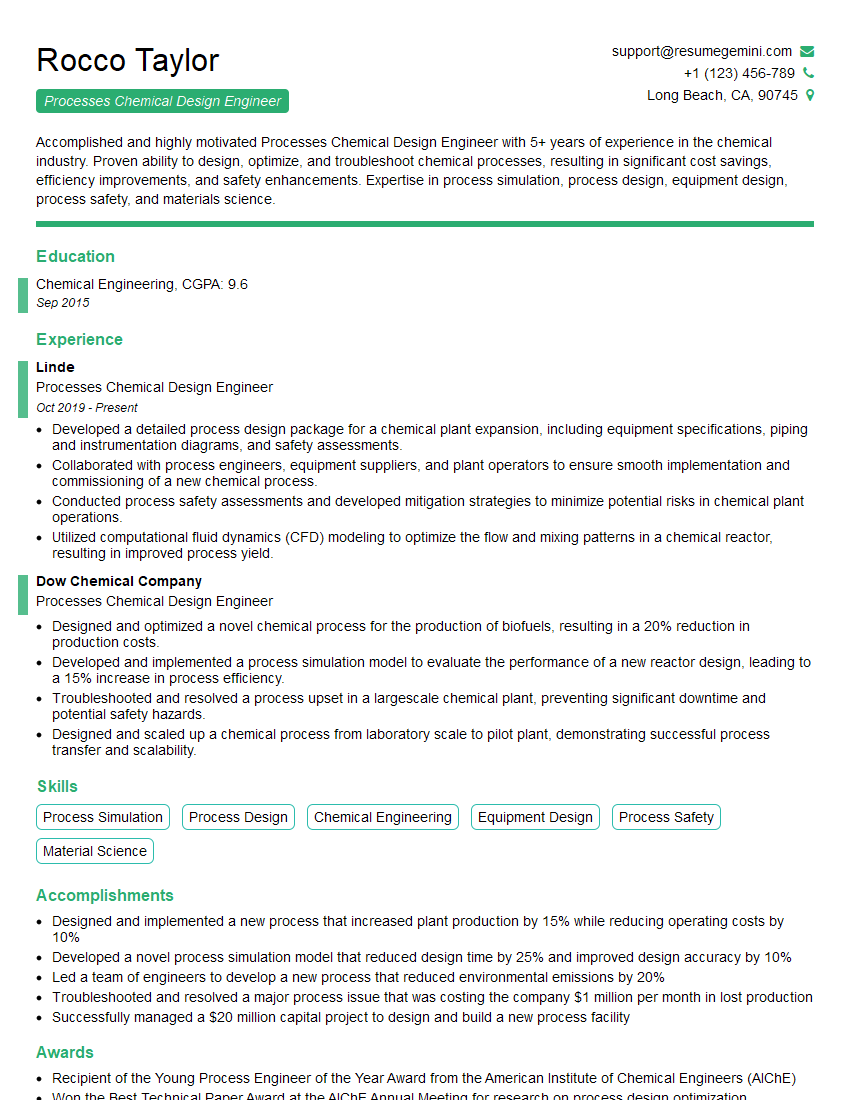

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Processes Chemical Design Engineer

1. What are your key responsibilities as a Processes Chemical Design Engineer?

As a Processes Chemical Design Engineer, my key responsibilities include designing, developing, and implementing processes for the production of chemicals. I also play a key role in developing and maintaining process safety systems, and in the optimization of existing processes to improve efficiency and quality.

2. Can you describe the process you follow when designing a new chemical process?

Process Design Steps

- Define the project scope and objectives

- Gather and analyze data on raw materials, products, and process conditions

- Develop process flow diagrams and equipment specifications

- Estimate capital and operating costs

- Conduct safety and environmental impact assessments

Project Evaluation and Implementation

- Evaluate the technical and economic feasibility of the proposed process

- Obtain regulatory approvals

- Supervise the construction and commissioning of the process

3. What are some of the challenges you have faced in your previous roles as a Processes Chemical Design Engineer?

- Designing a process to meet stringent environmental regulations

- Developing a cost-effective process for a new product

- Troubleshooting and optimizing an existing process

- Working with a multidisciplinary team to design a complex process

- Managing a project from concept to completion

4. What are your strengths and weaknesses as a Processes Chemical Design Engineer?

Strengths

- Strong technical skills in chemical engineering

- Excellent problem-solving and analytical skills

- Proven ability to design and optimize chemical processes

- Experience in working with a multidisciplinary team

- Excellent communication and presentation skills

Weaknesses

- Lack of experience in certain specialized areas of chemical engineering

- Can be slow to make decisions in some situations

5. What are your career goals?

My career goal is to become a world-renowned chemical engineer and to make a significant contribution to the field. I would like to develop new and innovative chemical processes that can help to solve some of the world’s most pressing problems, such as climate change and the need for sustainable energy.

6. What are your salary expectations?

My salary expectations are in line with the industry average for Processes Chemical Design Engineers with my level of experience and qualifications.

7. Why are you interested in working for our company?

I am interested in working for your company because I am impressed by your commitment to innovation and sustainability. I believe that my skills and experience would be a valuable asset to your team, and I am confident that I can make a significant contribution to your company.

8. What is your favorite chemical engineering software? Why?

My favorite chemical engineering software is Aspen HYSYS. It is a powerful and versatile software that can be used for a wide range of chemical engineering applications, including process simulation, design, and optimization. I find it to be user-friendly and efficient, and it produces accurate and reliable results.

9. Tell me about a time when you had to overcome a major obstacle in your work.

During the design of a new chemical process, I encountered a major obstacle when I realized that the process was not meeting the required safety standards. I worked closely with a team of engineers and safety experts to develop a solution that met all of the safety requirements without compromising the efficiency of the process.

10. What are your thoughts on the future of the chemical engineering industry?

I believe that the future of the chemical engineering industry is very bright. As the world faces challenges such as climate change and the need for sustainable energy, chemical engineers will be in high demand to develop new and innovative solutions. I am excited to be a part of this industry and to contribute to its future success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Processes Chemical Design Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Processes Chemical Design Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Process Chemical Design Engineer devises and plans the construction of chemical processing equipment, plants and facilities used in the production of chemicals and chemical products. To streamline operations and enhance efficiency, they leverage their know-how and technical proficiency in chemical engineering principles.

1. Process Design and Development

They are responsible for conceptualizing, designing, developing, and optimizing processes for the production and refining of assorted chemicals, petrochemicals, polymers, and pharmaceuticals.

- Conduct thorough research and feasibility studies to assess various design options and their impact on project objectives and constraints.

- Employ computer-aided design (CAD) software and simulation tools to create detailed process flow sheets and equipment specifications.

2. Equipment Selection and Specification

They determine the most appropriate equipment for the chemical process, considering factors such as capacity, efficiency, material compatibility, and safety.

- Prepare technical specifications for equipment, including pumps, reactors, heat exchangers, and control systems, ensuring they meet process requirements.

- Collaborate with vendors and contractors to procure and install equipment.

3. Process Optimization and Troubleshooting

They monitor and analyze process performance to identify areas for improvement and enhance efficiency.

- Conduct experiments and gather data to determine process parameters and optimize operating conditions.

- Troubleshoot process issues, identify root causes, and implement corrective measures to maintain optimal performance.

4. Safety and Environmental Compliance

They prioritize safety and environmental protection by designing processes that comply with industry regulations and standards.

- Incorporate safety features into process designs, such as containment systems and emergency shutdown procedures.

- Ensure processes meet environmental regulations, including emission control and waste management.

Interview Tips

To prepare for a Process Chemical Design Engineer interview, you should focus on demonstrating your technical expertise, problem-solving abilities, and communication skills.

1. Research the Company and Position

Understand the company’s business, industry, and specific needs for the role. Tailor your resume and interview responses to highlight your qualifications and how you can contribute to the organization.

2. Review Process Design Concepts

Refresh your knowledge of chemical engineering principles, process design methodologies, and equipment selection criteria. Be prepared to discuss your understanding of heat transfer, fluid flow, and reaction engineering.

3. Quantify Your Accomplishments

When describing your previous experiences, use specific metrics and data to demonstrate the impact of your work. For example, quantify improvements in process efficiency, cost reductions, or safety enhancements.

4. Highlight Problem-Solving Skills

Provide examples of how you identified and solved complex technical challenges. Emphasize your ability to analyze data, develop innovative solutions, and work effectively in a team environment.

5. Prepare for Technical Questions

Anticipate questions about process simulation software, equipment design calculations, and process optimization techniques. Practice answering these questions clearly and concisely.

6. Practice Your Communication Skills

Engineering interviews often involve presentations or case studies. Prepare to articulate your technical ideas clearly and persuasively to a non-technical audience.

7. Be Enthusiastic and Professional

Show genuine interest in the role and the company. Dress appropriately and maintain a professional demeanor throughout the interview process.

Next Step:

Now that you’re armed with the knowledge of Processes Chemical Design Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Processes Chemical Design Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini