Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Processing Talc and Borate Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Processing Talc and Borate Supervisor so you can tailor your answers to impress potential employers.

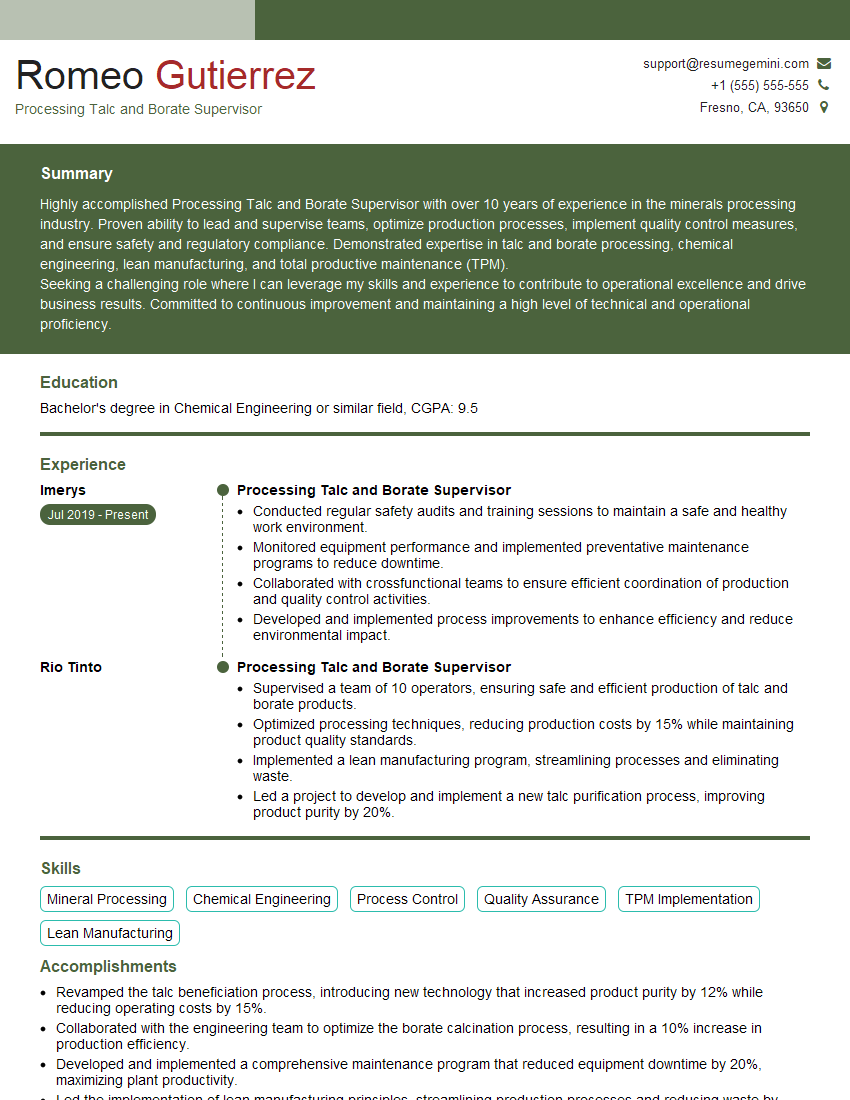

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Processing Talc and Borate Supervisor

1. Which critical parameters do you monitor to ensure the proper operation of the talc and borate processing plant?

To ensure the proper operation of the talc and borate processing plant, I closely monitor several critical parameters. These include:

- Checking feed rates of raw materials to optimize production efficiency and minimize waste.

- Monitoring temperatures and pressures throughout the process to ensure optimal conditions and prevent equipment damage.

- Analyzing product quality using techniques such as particle size distribution and chemical composition to meet customer specifications and maintain consistency.

- Tracking equipment performance, including vibration analysis and predictive maintenance, to identify potential issues and prevent breakdowns.

2. Describe the key steps involved in the processing of talc and borate.

Crushing and Grinding

- Raw talc and borate ores are crushed using jaw crushers and cone crushers to reduce their size.

- The crushed materials are then ground into finer particles using ball mills or roller mills.

Beneficiation

- Beneficiation techniques such as flotation and magnetic separation are employed to separate talc and borate minerals from impurities.

- This process enhances the purity and quality of the final products.

Drying

- The beneficiated minerals are dried using rotary dryers or fluidized bed dryers to remove moisture.

- Proper drying ensures the stability and prevents caking during storage and transportation.

3. How do you maintain a safe and efficient work environment in the plant?

Maintaining a safe and efficient work environment in the plant is crucial. I implement the following measures:

- Enforcing strict adherence to safety protocols, including proper use of personal protective equipment and following established operating procedures.

- Conducting regular safety inspections to identify and mitigate potential hazards.

- Providing comprehensive safety training to all employees, ensuring they are well-informed about potential risks and emergency procedures.

- Promoting a culture of safety awareness and open communication, encouraging employees to report any unsafe conditions or practices.

4. What techniques do you employ to optimize energy consumption in the plant?

Optimizing energy consumption is essential for sustainability and cost reduction. I utilize the following techniques:

- Regularly monitoring energy usage and identifying areas for improvement.

- Upgrading equipment with energy-efficient models, such as high-efficiency motors and lighting systems.

- Implementing process optimizations, such as reducing idle time and adjusting production schedules to minimize energy waste.

- Encouraging employee involvement in energy conservation initiatives.

5. How do you manage the quality of the final products?

Ensuring the quality of final products is paramount. I implement a comprehensive quality management system that includes:

- Establishing clear quality standards and specifications.

- Performing regular quality checks throughout the production process.

- Implementing statistical process control techniques to monitor and improve product quality.

- Obtaining customer feedback to identify areas for improvement.

6. What experience do you have in managing a team of operators in a processing plant?

I have extensive experience in managing a team of operators in a processing plant. My responsibilities include:

- Providing clear instructions and guidance to ensure efficient and safe operations.

- Motivating and training team members to enhance their skills and productivity.

- Monitoring operator performance and providing feedback to support continuous improvement.

- Creating a positive and collaborative work environment that fosters teamwork and accountability.

7. How do you handle unexpected equipment breakdowns or process disruptions?

Unexpected equipment breakdowns or process disruptions are inevitable. I approach these situations by:

- Prioritizing safety and isolating the affected area to prevent further incidents.

- Quickly assessing the situation and identifying the root cause of the problem.

- Working with a team of technicians to repair or replace equipment and restore operations.

- Implementing corrective actions to prevent similar incidents from occurring in the future.

8. What are the challenges you anticipate in this role, and how do you plan to overcome them?

I anticipate several challenges in this role, including:

- Maintaining high product quality: I plan to implement a rigorous quality control system and work closely with the quality assurance team to ensure that all products meet specifications.

- Optimizing production efficiency: I plan to analyze production data, identify bottlenecks, and implement process improvements to increase efficiency and reduce costs.

- Managing a diverse team: I plan to foster a collaborative and inclusive work environment, providing clear communication, support, and professional development opportunities to all team members.

9. What are your career goals, and how do you see this role contributing to your professional development?

My ultimate career goal is to become a plant manager in the mining industry. I believe that this role as Processing Talc and Borate Supervisor will provide me with the necessary experience and skills to achieve my goal. specifically, I expect to develop the following:

- Expertise in talc and borate processing operations.

- Strong leadership and management skills.

- In-depth understanding of plant operations and optimization.

10. Why are you interested in working for our company?

I am excited about the opportunity to work for your company because of its reputation for being a leader in the mining industry. I believe that my skills and experience would be a valuable asset to your team. I am particularly impressed with your company’s commitment to sustainability and innovation, and I am eager to contribute to your continued success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Processing Talc and Borate Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Processing Talc and Borate Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Processing Talc and Borate Supervisor plays a pivotal role in overseeing the production process of talc and borate minerals, ensuring efficient operations and product quality.

1. Production Management

Supervising and directing all production activities, including crushing, grinding, screening, and packaging of talc and borate.

Optimizing production processes to maximize output, minimize costs, and meet customer specifications.

2. Quality Control

Establishing and maintaining quality control standards for talc and borate products.

Conducting regular inspections to ensure products meet quality specifications and standards.

3. Equipment Maintenance

Ensuring proper maintenance and repair of processing equipment to prevent breakdowns and maintain production efficiency.

coordinating with maintenance teams to schedule repairs and minimize downtime.

4. Safety Management

Implementing and enforcing safety procedures to ensure a safe working environment.

Providing safety training to employees and ensuring compliance with safety regulations.

Interview Tips

Preparing for the interview as a Processing Talc and Borate Supervisor requires a thorough understanding of the role’s responsibilities and key industry knowledge.

1. Research the company and industry:

Study the company’s website, mission statement, and industry trends to demonstrate your interest and knowledge.

Research the specific types of talc and borate products the company produces, as well as their applications.

2. Highlight relevant experience and skills:

Emphasize your experience in supervising production processes, maintaining quality standards, and ensuring safety.

Showcase your knowledge of talc and borate processing techniques, equipment, and safety regulations.

3. Prepare examples of your accomplishments:

Provide specific examples of how you have successfully managed production operations, ensured product quality, and implemented safety measures.

Use the STAR method (Situation, Task, Action, Result) to structure your answers and highlight your accomplishments.

4. Demonstrate your problem-solving and decision-making skills:

Share examples of how you have resolved production issues, improved processes, or made difficult decisions in a timely and effective manner.

Emphasize your ability to analyze data, identify root causes, and develop innovative solutions.

5. Be prepared for technical questions:

The interviewer may ask technical questions about talc and borate processing techniques, equipment, and safety procedures.

Review your industry knowledge and be ready to discuss specific examples of your expertise.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Processing Talc and Borate Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!