Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Product Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

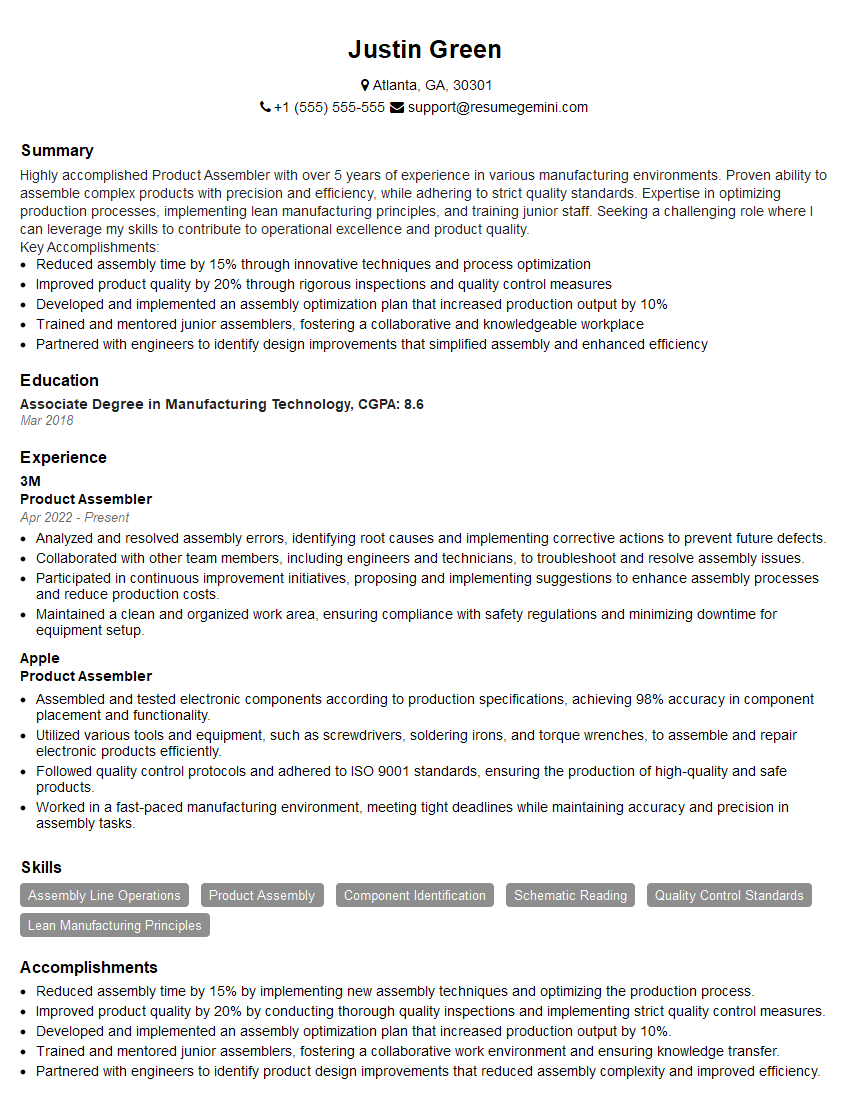

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Product Assembler

1. What are the different types of assembly lines and their key characteristics?

There are three main types of assembly lines: manual, semi-automated, and fully automated. Manual assembly lines are operated entirely by hand, while semi-automated lines use a combination of manual labor and machines. Fully automated lines are operated entirely by machines.

- Manual assembly lines are typically used for low-volume production or for products that require a high degree of customization. They are relatively inexpensive to set up and operate, but they can be slow and inefficient.

- Semi-automated assembly lines are used for medium-volume production or for products that require a moderate degree of customization. They are more expensive to set up and operate than manual lines, but they can be more efficient and productive.

- Fully automated assembly lines are used for high-volume production or for products that require a low degree of customization. They are the most expensive to set up and operate, but they can be the most efficient and productive.

2. What are the key factors to consider when designing an assembly line?

Factors to consider include:

- Product volume – The number of units that need to be produced per hour, day, or week.

- Product complexity – The number and complexity of the components that make up the product.

- Available space – The amount of space available for the assembly line.

- Budget – The amount of money that is available to invest in the assembly line.

Additional factors to consider include:

- Ergonomics – The design of the assembly line should be comfortable and safe for workers.

- Efficiency – The assembly line should be designed to minimize waste and maximize productivity.

- Flexibility – The assembly line should be able to adapt to changes in product design or production volume.

3. What are some of the common challenges faced by product assemblers?

Some of the common challenges faced by product assemblers include:

- Meeting production targets – Product assemblers are often under pressure to meet production targets, which can lead to stress and errors.

- Working with tight tolerances – Product assemblers often have to work with tight tolerances, which can be difficult and time-consuming.

- Repetitive work – Product assembly work can be repetitive and monotonous, which can lead to boredom and fatigue.

- Physical demands – Product assembly work can be physically demanding, which can lead to injuries.

4. What are some of the key skills and qualities of a successful product assembler?

Some of the key skills and qualities of a successful product assembler include:

- Attention to detail – Product assemblers must be able to pay attention to detail and follow instructions carefully.

- Dexterity – Product assemblers must have good dexterity and be able to work with small parts.

- Patience – Product assembly work can be repetitive and monotonous, so assemblers must be patient and able to work for long periods of time.

- Physical fitness – Product assembly work can be physically demanding, so assemblers must be in good physical condition.

- Teamwork skills – Product assemblers often work in teams, so they must be able to work well with others.

5. What are some of the latest trends in product assembly?

Some of the latest trends in product assembly include:

- Increased use of automation – Automation is being used to improve efficiency and productivity in product assembly.

- Use of modular design – Modular design makes it easier to assemble and disassemble products, which can save time and money.

- Focus on ergonomics – Ergonomics is being used to improve the safety and comfort of product assemblers.

- Use of lean manufacturing principles – Lean manufacturing principles are being used to reduce waste and improve efficiency in product assembly.

6. What are some of the challenges facing the product assembly industry?

Some of the challenges facing the product assembly industry include:

- Rising labor costs – Labor costs are rising in many parts of the world, which is making it more expensive to manufacture products.

- Increasing competition – The product assembly industry is becoming increasingly competitive, which is putting pressure on companies to reduce costs and improve efficiency.

- Changing consumer demands – Consumer demands are constantly changing, which is forcing companies to adapt their product assembly processes.

- Technological advances – Technological advances are changing the way that products are assembled, which is creating new challenges for companies.

7. What are some of the opportunities for the product assembly industry?

Some of the opportunities for the product assembly industry include:

- Growing demand for products – The demand for products is growing in many parts of the world, which is creating opportunities for product assembly companies.

- New technologies – New technologies are creating new opportunities for product assembly companies to improve their efficiency and productivity.

- Changing consumer trends – Changing consumer trends are creating opportunities for product assembly companies to develop new products and services.

- Globalization – Globalization is creating opportunities for product assembly companies to expand their reach into new markets.

8. What are your strengths as a product assembler?

My strengths as a product assembler include my attention to detail, my dexterity, my patience, my physical fitness, and my teamwork skills. I am also a quick learner and I am always willing to take on new challenges.

9. What are your weaknesses as a product assembler?

My weaknesses as a product assembler include my lack of experience in working with some types of products and my tendency to be a perfectionist. I am also not as fast as some other assemblers.

10. What are your career goals?

My career goal is to become a supervisor in a product assembly company. I would like to use my skills and experience to help my team meet production targets and improve quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Product Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Product Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Product Assemblers are the backbone of any manufacturing operation, working on assembly lines to put together products according to specifications. Their key responsibilities include:

1. Precision Assembly

Assembling products with accuracy and precision, ensuring that all components are securely fastened and properly aligned.

- Following assembly instructions and blueprints

- Using appropriate tools and equipment

- Inspecting assembled products for defects

2. Quality Control

Maintaining high standards of quality, identifying and correcting any errors or defects in the assembly process.

- Adhering to quality control procedures

- Using measuring devices and gauges

- Reporting any quality issues

3. Efficiency and Productivity

Working efficiently to meet production targets without compromising quality.

- Optimizing assembly processes

- Minimizing waste and downtime

- Staying updated with new assembly techniques

4. Teamwork and Communication

Collaborating with team members to ensure smooth assembly operations and open communication with supervisors and quality inspectors.

- Working in a fast-paced environment

- Providing and receiving feedback

- Resolving assembly issues

Interview Tips

Preparing for a Product Assembler interview requires thorough research and a focus on demonstrating your skills and experience. Here are some tips to ace your interview:

1. Research the Company and Role

Thoroughly research the company’s industry, products, and assembly processes to show that you are well-informed and interested in the specific role.

- Visit the company website and social media pages

- Read industry publications and articles

- Connect with employees on LinkedIn

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience, such as precision assembly, quality control, and teamwork. Use specific examples to demonstrate your abilities.

- Quantify your accomplishments using numbers

- Use the STAR method to describe your experiences

- Prepare examples of your problem-solving and decision-making skills

3. Be Prepared for Technical Questions

Anticipate technical questions related to assembly processes, tools, and quality control. Practice answering questions about your understanding of assembly techniques, blueprint interpretation, and defect detection.

- Review common assembly tools and equipment

- Familiarize yourself with industry standards and best practices

- Practice troubleshooting hypothetical assembly problems

4. Showcase Your Teamwork and Communication Skills

Product Assemblers work in team environments, so highlight your teamwork and communication abilities. Provide examples of successful collaborations and how you contributed to resolving assembly issues.

- Emphasize your ability to work effectively in a fast-paced environment

- Share examples of how you provided feedback and collaborated with colleagues

- Explain how you stay updated with new assembly techniques

5. Ask Thoughtful Questions

At the end of the interview, prepare thoughtful questions to demonstrate your interest and engagement. Ask about the company’s assembly processes, quality standards, and growth opportunities.

- Inquire about the company’s commitment to quality

- Ask about the opportunities for professional development

- Express your enthusiasm for the role and the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Product Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.