Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Production Associate interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Production Associate so you can tailor your answers to impress potential employers.

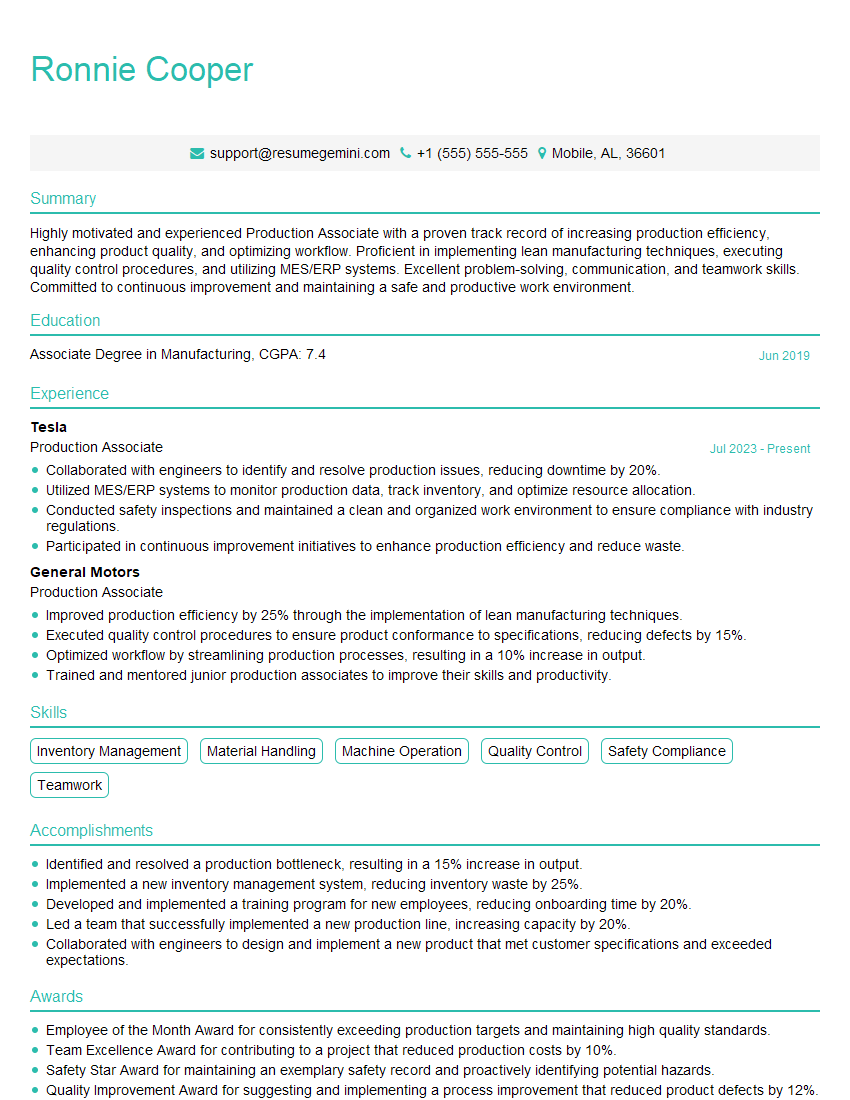

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Associate

1. Describe the key responsibilities of a Production Associate in a manufacturing environment?

As a Production Associate, I would be responsible for the following key tasks in a manufacturing environment:

- Operate and monitor production equipment to ensure efficient and safe production.

- Inspect and test products to maintain quality standards.

- Assemble and package products according to specifications.

- Monitor production processes to identify and resolve any issues.

- Maintain a clean and organized work area.

- Follow safety protocols and regulations.

2. Explain the different types of production processes and their applications?

Assembly line production

- Used in mass production of standardized products.

- Products are moved along a conveyor belt, with each worker performing a specific task.

- Efficient and cost-effective for high-volume production.

Batch production

- Used to produce smaller batches of customized products.

- Products are processed in batches, with each batch having its own unique set of specifications.

- Allows for greater flexibility and customization.

Job shop production

- Used to produce one-of-a-kind or low-volume products.

- Production is based on customer orders.

- Requires high levels of skill and flexibility from workers.

3. Describe the principles of lean manufacturing and how they can be implemented in a production environment?

Lean manufacturing focuses on eliminating waste and maximizing efficiency throughout the production process. Key principles include:

- Identifying and eliminating non-value-added activities.

- Creating a continuous flow of production.

- Reducing inventory levels.

- Empowering employees to identify and solve problems.

- Continuous improvement.

These principles can be implemented through techniques such as:

- Value stream mapping.

- Just-in-time inventory.

- Kanban boards.

- Total productive maintenance.

4. Explain the importance of quality control in manufacturing and discuss different quality control techniques?

Quality control is crucial in manufacturing to ensure that products meet customer requirements and industry standards. Key techniques include:

- Statistical process control (SPC): Monitoring and analyzing production data to identify and control variation.

- Inspection and testing: Verifying the quality of products at various stages of production.

- Root cause analysis: Identifying and eliminating the root causes of quality problems.

- Continuous improvement: Regularly reviewing and enhancing quality control processes.

By implementing these techniques, manufacturers can improve product quality, reduce defects, and increase customer satisfaction.

5. Describe the role of maintenance in a production environment and discuss different maintenance strategies?

Maintenance plays a vital role in keeping production equipment and facilities operating efficiently. Key strategies include:

- Preventive maintenance: Regularly scheduled maintenance to prevent equipment breakdowns.

- Predictive maintenance: Using sensors and data analysis to predict and prevent equipment failures.

- Corrective maintenance: Repairing or replacing equipment after it has failed.

- Total productive maintenance (TPM): A comprehensive approach that involves operators in maintenance activities.

Effective maintenance can minimize equipment downtime, improve production efficiency, and reduce maintenance costs.

6. Explain the different types of manufacturing materials and their properties?

There are various types of manufacturing materials, each with its unique properties:

- Metals (e.g., steel, aluminum, copper): Strong, durable, and good conductors of electricity.

- Plastics (e.g., polyethylene, polypropylene): Lightweight, flexible, and resistant to corrosion.

- Ceramics (e.g., porcelain, glass): Hard, brittle, and heat-resistant.

- Composites (e.g., fiberglass, carbon fiber): Combine the properties of different materials to achieve specific characteristics.

Selecting the appropriate material for a particular application depends on factors such as strength, durability, cost, and availability.

7. Describe the different types of manufacturing processes used in the production of metal parts?

- Casting: Creating metal parts by pouring molten metal into a mold.

- Forging: Shaping metal by hammering or pressing it.

- Machining: Removing material from metal using cutting tools.

- Welding: Joining metal parts together using heat and pressure.

- Fabrication: Assembling metal parts into larger structures.

Each process has its own advantages and disadvantages, and the choice of process depends on the specific requirements of the application.

8. Explain the principles of quality assurance in manufacturing and discuss different quality assurance techniques?

Quality assurance focuses on preventing defects and ensuring that products meet quality standards throughout the manufacturing process. Key techniques include:

- Establishing clear quality standards and specifications.

- Implementing quality control processes at all stages of production.

- Providing training to employees on quality assurance practices.

- Regularly reviewing and updating quality assurance systems.

Effective quality assurance can improve product quality, reduce costs, and enhance customer satisfaction.

9. Describe the different types of manufacturing equipment used in a production environment?

- Machine tools: Used for shaping and cutting metal, such as lathes, mills, and drills.

- Material handling equipment: Used for moving and positioning materials, such as forklifts and conveyors.

- Assembly equipment: Used for assembling products, such as robots and automated assembly lines.

- Inspection equipment: Used for checking the quality of products, such as gauges and measuring devices.

- Safety equipment: Used to protect workers from hazards, such as guards and safety glasses.

The selection of equipment depends on the specific requirements of the manufacturing process.

10. Explain the importance of safety in a manufacturing environment and discuss different safety procedures?

Safety is paramount in a manufacturing environment. Key safety procedures include:

- Establishing and enforcing safety rules and regulations.

- Providing training to employees on safety practices.

- Maintaining a clean and organized work area.

- Using appropriate personal protective equipment (PPE).

- Regularly inspecting equipment and facilities for safety hazards.

Effective safety measures can prevent accidents, minimize risks, and ensure a safe working environment for employees.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Associate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Associate‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Associates are responsible for ensuring the smooth operation of a production line. They are responsible for the safety and quality of the products being produced.

1. Machine Operation

Production Associates are responsible for the operation of various machines. They must be able to follow instructions and operate the machines safely and efficiently.

- Operate and maintain production machinery.

- Monitor production processes and make adjustments as needed.

2. Quality Control

Production Associates are responsible for the quality of the products being produced. They must be able to identify and correct defects.

- Inspect products for defects.

- Sort and pack products according to specifications.

3. Material Handling

Production Associates are responsible for the handling of materials. They must be able to move materials safely and efficiently.

- Load and unload materials from machines.

- Move materials around the production area.

4. Maintenance and Cleaning

Production Associates are responsible for the maintenance and cleaning of the production area. They must be able to keep the area clean and free of hazards.

- Clean and maintain production equipment.

- Keep the production area clean and organized.

Interview Tips

Preparing for an interview can be daunting, but with the right strategies, you can increase your chances of success.

1. Research the Company and the Position

The first step is to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position.

- Visit the company’s website.

- Read about the company in the news.

- Talk to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be Yourself

It’s important to be yourself during the interview. Don’t try to be someone you’re not. The interviewer will be able to tell if you’re being fake, and it will hurt your chances of getting the job.

- Be confident in your abilities.

- Be honest about your experience and qualifications.

- Be enthusiastic about the position.

4. Dress Professionally

The way you dress for an interview sends a message to the interviewer. Make sure you dress professionally and appropriately for the position you are applying for.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing too much jewelry or makeup.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Associate interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!