Are you gearing up for an interview for a Production Checker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Production Checker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

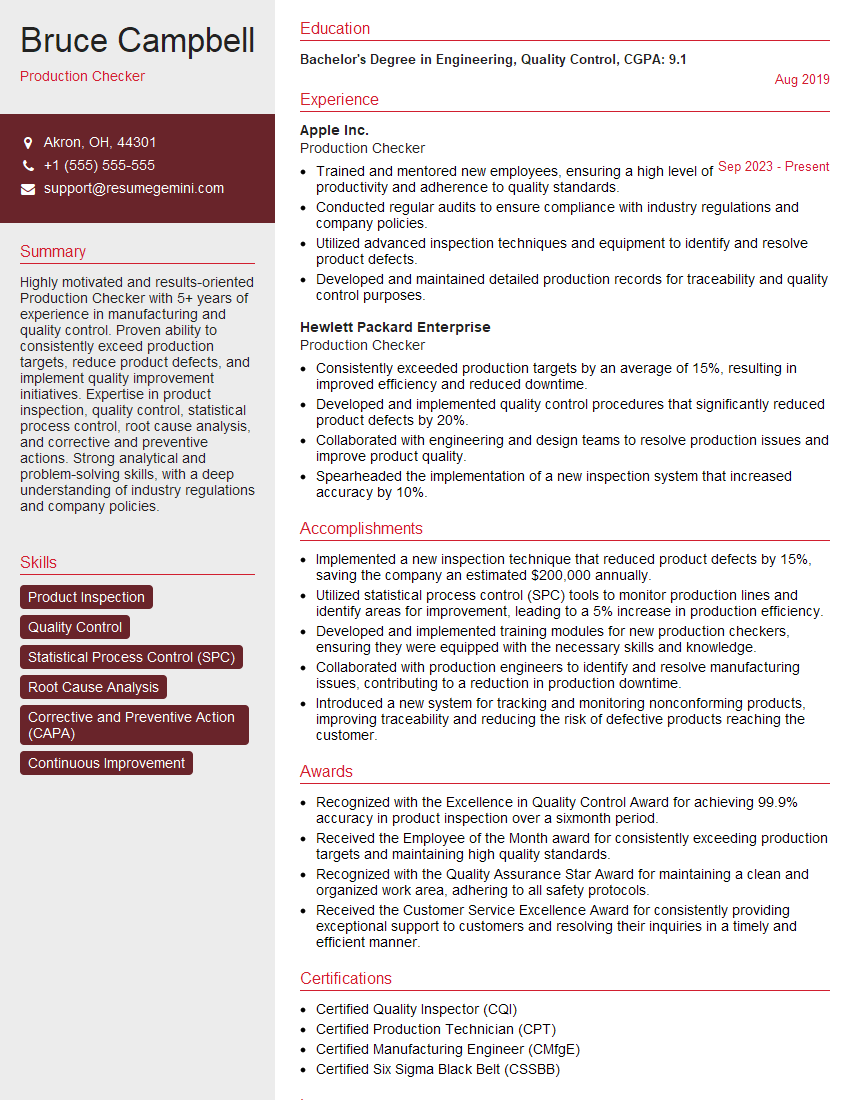

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Checker

1. How do you ensure the accuracy of production data?

To ensure the accuracy of production data, I employ a comprehensive approach that encompasses the following steps:

- Regular Data Validation: I routinely cross-check data from multiple sources to identify and rectify any discrepancies or errors.

- Quality Control Checks: I implement stringent quality control measures throughout the production process, including regular audits and inspections to maintain data integrity.

2. Describe the process you follow for identifying and resolving production issues.

Identifying Production Issues

- Active Monitoring: I continuously monitor production processes to proactively identify any potential issues.

- Real-Time Alerts: I leverage monitoring systems that provide real-time alerts, enabling me to respond promptly to emerging problems.

Resolving Production Issues

- Root Cause Analysis: I conduct thorough root cause analysis to determine the underlying cause of production issues.

- Problem-Solving: I employ analytical and problem-solving skills to develop and implement effective solutions.

- Collaboration: I collaborate with relevant stakeholders, such as production team members and engineers, to gather insights and resolve issues efficiently.

3. How do you manage production schedules and ensure timely delivery of products?

I utilize a combination of planning, coordination, and monitoring to effectively manage production schedules and ensure timely delivery:

- Production Planning: I collaborate with planning teams to develop realistic and optimized production schedules.

- Resource Allocation: I allocate resources efficiently to balance production capacity and meet delivery deadlines.

- Progress Monitoring: I regularly monitor production progress and identify potential delays to take proactive action.

- Communication: I maintain open communication with stakeholders to keep them informed about production status and any potential schedule adjustments.

4. Describe your understanding of production quality control processes.

Production quality control processes are essential for ensuring the production of high-quality products. My understanding of these processes includes:

- Inspection and Testing: I conduct thorough inspections and testing of raw materials, in-process products, and finished goods to identify and prevent defects.

- Statistical Process Control (SPC): I utilize SPC techniques to monitor and analyze production data to identify and eliminate variation, improving overall quality.

- Corrective and Preventive Actions (CAPA): I implement CAPA measures to address non-conformances, prevent their recurrence, and continually improve production processes.

5. How do you prioritize and manage multiple production orders?

To prioritize and manage multiple production orders effectively, I employ a methodical approach:

- Order Classification: I categorize orders based on priority, delivery deadlines, and customer requirements.

- Resource Allocation: I allocate resources strategically to ensure that critical orders are processed first.

- Scheduling Optimization: I optimize production schedules to minimize delays and maximize efficiency.

- Communication: I maintain clear communication with customers and production teams to keep them informed about order status and any potential adjustments.

6. How do you ensure compliance with industry regulations and quality standards in production?

To ensure compliance with industry regulations and quality standards, I adhere to the following practices:

- Regulatory Knowledge: I stay up-to-date with industry regulations and quality standards relevant to my role.

- Compliance Audits: I conduct regular internal and external audits to assess compliance with established standards.

- Corrective Actions: I promptly address any non-conformances identified during audits and implement corrective actions to maintain compliance.

- Quality Assurance: I engage in continuous quality assurance activities to ensure that production processes and products meet or exceed established standards.

7. How do you handle production emergencies or unexpected events?

In the event of production emergencies or unexpected events, I follow a structured approach:

- Rapid Response: I respond swiftly to identify the nature and severity of the emergency.

- Problem Assessment: I assess the potential impact on production, safety, and quality.

- Action Plan Development: I develop and implement a clear action plan to mitigate the situation effectively.

- Communication: I communicate regularly with stakeholders to provide updates and coordinate efforts.

- Continuous Monitoring: I monitor the situation closely to ensure that the emergency is resolved efficiently and effectively.

8. How do you stay updated with the latest production technologies and best practices?

To stay updated with the latest production technologies and best practices, I engage in the following activities:

- Industry Conferences and Webinars: I attend industry conferences and webinars to learn about innovative technologies and emerging trends.

- Professional Development: I participate in professional development programs and certifications to enhance my knowledge and skills.

- Collaboration: I collaborate with peers and experts in the field to exchange ideas and share best practices.

- Industry Publications: I regularly read industry publications and research articles to stay informed about advancements in production techniques.

9. Describe a challenging production issue you resolved and the steps you took to overcome it.

In a previous role, we encountered a significant production issue where a critical production machine malfunctioned, halting production. I took the following steps to resolve the issue:

- Rapid Diagnosis: I quickly diagnosed the issue by analyzing error codes and consulting with technical experts.

- Problem-Solving: I worked with an engineering team to identify the root cause of the malfunction and develop a solution.

- Temporary Resolution: I implemented a temporary workaround to minimize production downtime while the permanent solution was being developed.

- Permanent Solution: I oversaw the repair and installation of a new part, ensuring that the machine was fully operational.

- Lessons Learned: I documented the issue and the steps taken to resolve it for future reference and continuous improvement.

10. How do you contribute to continuous improvement initiatives in production?

I actively participate in continuous improvement initiatives in production through the following activities:

- Process Analysis: I analyze production processes to identify areas for improvement and develop optimization strategies.

- Employee Feedback: I gather feedback from production team members to gain insights into potential pain points and areas where improvements can be made.

- Data-Driven Decisions: I utilize data and metrics to support improvement initiatives and measure their effectiveness.

- Benchmarking: I benchmark our production processes against industry best practices to identify opportunities for improvement.

- Collaboration: I collaborate with stakeholders across departments to facilitate knowledge sharing and foster a culture of continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Production Checker, you will play a crucial role in ensuring quality and maintaining production efficiency. Here are the key responsibilities you will be responsible for:

1. Quality Control Inspections

Conduct thorough inspections of products or components to verify their compliance with quality standards, specifications, and customer requirements.

- Examine products for defects, errors, or deviations from established standards.

- Use measuring instruments and testing equipment to ensure dimensional accuracy, functionality, and adherence to customer specifications.

2. Production Monitoring

Monitor production processes to ensure they are operating smoothly and efficiently.

- Observe production lines and equipment for any potential issues or deviations from standard procedures.

- Identify and address bottlenecks or inefficiencies in the production process.

3. Documentation and Record Keeping

Maintain accurate records of production checks, inspections, and quality control data.

- Document inspection findings, test results, and any non-conformances or deviations.

- Prepare and maintain quality control reports, charts, and other documentation.

4. Communication and Collaboration

Communicate effectively with production staff, supervisors, and management to report findings, initiate corrective actions, and provide feedback.

- Provide timely and clear information on quality issues and suggest improvements to production processes.

- Collaborate with other departments, such as engineering and maintenance, to troubleshoot and resolve quality-related problems.

Interview Tips

To ace your interview for a Production Checker position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This shows the interviewer that you are genuinely interested in the role and the company’s mission.

- Visit the company’s website, read industry publications, and attend relevant events.

- Identify the company’s competitors and be prepared to discuss their strengths and weaknesses.

2. Highlight Your Quality Control Expertise

Emphasize your experience and skills in quality control inspections and production monitoring. Provide specific examples of your ability to identify and resolve quality issues.

- Quantify your results whenever possible, such as the number of defects detected or the percentage reduction in production errors.

- Explain how you use measuring instruments and testing equipment to ensure accuracy and compliance with specifications.

3. Demonstrate Attention to Detail and Analytical Skills

Production Checkers need to be highly detail-oriented and analytical. Show the interviewer that you possess these skills by providing examples of your ability to detect and resolve even minor quality issues.

- Discuss your experience in using statistical methods or quality control tools to improve production processes.

- Explain how you identify and analyze trends in quality data to identify potential problems.

4. Emphasize Communication and Teamwork Skills

Effective communication and teamwork are essential for Production Checkers. Showcase your ability to work independently and as part of a team to solve problems and ensure quality.

- Provide examples of how you have communicated quality issues effectively to production staff and management.

- Explain how you have collaborated with other departments to improve production processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Checker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!