Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Control Coordinating Clerk position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

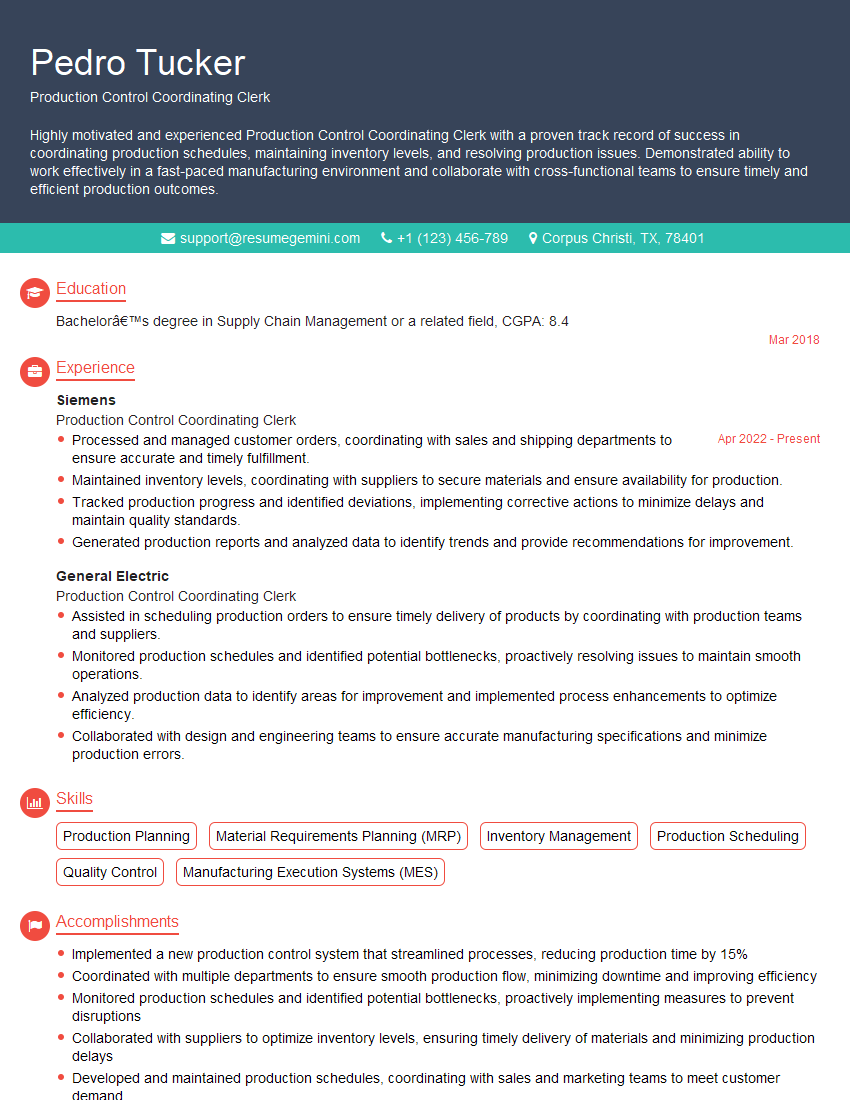

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Control Coordinating Clerk

1. Describe the key responsibilities of a Production Control Coordinating Clerk?

- Scheduling production operations to ensure efficient use of resources

- Coordinating with production staff, suppliers, and customers

- Tracking production progress and identifying potential bottlenecks

- Preparing and maintaining production records and reports

- Updating production control systems with relevant information

2. Explain how you would approach a production schedule that is behind schedule?

- Assess the situation: Analyze the reasons for the delay and identify areas where improvements can be made.

- Communicate with stakeholders: Inform production staff, suppliers, and customers about the delay and discuss potential solutions.

- Reprioritize tasks: Adjust the production schedule to prioritize critical tasks and minimize further delays.

- Increase resources: If necessary, allocate additional resources such as equipment or staff to accelerate production.

- Monitor progress: Track the progress of the revised schedule and make adjustments as needed.

3. What are the key performance indicators (KPIs) you would use to measure the effectiveness of production control?

- Production efficiency: Percentage of time production equipment is in use

- Lead time: Time taken from order placement to product delivery

- Throughput: Number of units produced per hour or day

- Inventory levels: Maintain optimal inventory levels to avoid shortages or overstocking

- Customer satisfaction: Measure customer feedback on product quality and delivery times

4. How would you handle a supplier that is consistently delivering late deliveries?

- Communicate effectively: Discuss the issue with the supplier and understand their reasons for the delays.

- Investigate the cause: Determine if the delays are due to production issues, transportation problems, or other factors.

- Explore alternative suppliers: Consider working with other suppliers as a backup to ensure timely deliveries.

- Negotiate penalties: Establish clear consequences for late deliveries and enforce them when necessary.

- Monitor and improve: Track the supplier’s performance and provide feedback to help them improve their delivery reliability.

5. Describe the role of technology in production control and how you would leverage it?

- Production planning software: Use software to optimize production schedules, track progress, and identify bottlenecks.

- Inventory management systems: Implement systems to maintain optimal inventory levels and streamline inventory processes.

- Data analytics: Analyze production data to identify trends, improve efficiency, and make informed decisions.

- Real-time monitoring systems: Monitor production equipment and processes in real-time to detect any deviations and respond quickly.

- Mobile applications: Utilize mobile apps to access production information remotely and facilitate communication among staff.

6. How would you ensure the accuracy and integrity of production control data?

- Establish clear data entry procedures: Train staff on proper data entry methods to minimize errors.

- Implement data validation processes: Set up automated checks to verify the accuracy of data entered into the system.

- Perform regular data audits: Conduct periodic audits to identify and correct any errors in the production control data.

- Train staff on data integrity: Educate staff on the importance of data integrity and the consequences of providing inaccurate information.

- Establish clear guidelines for data access: Limit access to production control data to authorized personnel only.

7. What is the importance of communication in production control and how would you foster effective communication?

- Regular team meetings: Hold regular meetings with production staff to share updates, discuss issues, and make decisions.

- Establish communication channels: Set up clear communication channels such as email, instant messaging, or video conferencing.

- Use technology to facilitate communication: Leverage technology such as project management software or instant messaging to streamline communication.

- Provide clear instructions and feedback: Ensure that production staff understands instructions and provide regular feedback to improve performance.

- Foster a culture of open communication: Create an environment where staff feels comfortable raising concerns and asking questions.

8. How would you handle a situation where production staff are not meeting performance expectations?

- Gather data: Collect data on production performance, identify areas where staff are falling short, and analyze the reasons for the underperformance.

- Provide feedback and training: Communicate the performance expectations clearly and provide training or support to help staff improve their skills.

- Set clear goals and timelines: Establish specific performance goals and deadlines to provide staff with clear targets to work towards.

- Monitor progress and provide support: Track the progress of staff and offer support and guidance to help them overcome challenges.

- Take disciplinary action if necessary: If staff consistently fail to meet performance expectations after receiving support, consider taking disciplinary action to address the issue.

9. What are the key challenges you anticipate in this role and how would you overcome them?

- Keeping up with production demands: Work closely with production staff to anticipate and meet production demands, optimize production schedules, and identify potential bottlenecks.

- Handling unexpected events: Develop contingency plans to address unexpected events such as equipment failures or supplier delays, and communicate these plans to relevant stakeholders.

- Managing a large volume of data: Leverage technology and efficient data management practices to organize and analyze production data, and identify trends and areas for improvement.

- Collaborating with various departments: Foster strong relationships with other departments such as purchasing, engineering, and sales to ensure smooth communication and coordination.

- Staying up-to-date with industry best practices: Attend industry events, read trade publications, and participate in professional development activities to stay abreast of new technologies and best practices in production control.

10. Why should we hire you for this role?

- Relevant experience: Highlight your previous experience in production control or a related field, emphasizing your skills in scheduling, coordination, and data management.

- Technical proficiency: Demonstrate your proficiency in production control software and other relevant technologies, and explain how you have used them to improve production efficiency.

- Strong communication and interpersonal skills: Emphasize your ability to communicate effectively with production staff, suppliers, and other stakeholders, and build strong working relationships.

- Problem-solving and analytical abilities: Describe your ability to identify and solve production problems, analyze data, and make sound decisions.

- Enthusiasm for continuous improvement: Express your passion for production control and your desire to continuously improve processes and find innovative solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Control Coordinating Clerk.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Control Coordinating Clerk‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Production Control Coordinating Clerk plays a crucial role in ensuring smooth and efficient production processes within an organization. Their key responsibilities include:

1. Production Planning and Scheduling

Coordinating the planning and scheduling of production activities, ensuring that all necessary materials and resources are available.

2. Inventory Management

Maintaining accurate inventory records, monitoring stock levels, and initiating reorders when necessary.

3. Quality Control

Monitoring production processes to ensure that quality standards are met, and coordinating with the quality control team to resolve any issues.

4. Customer Service

Interfacing with customers to address inquiries, resolve issues, and coordinate delivery schedules.

Interview Tips

To ace the interview for a Production Control Coordinating Clerk position, candidates should consider the following preparation tips:

1. Understand the Job Requirements

Thoroughly review the job description and identify the key responsibilities and qualifications required for the role.

2. Prepare for Common Interview Questions

Anticipate questions related to production planning, inventory management, quality control, and customer service. Prepare specific examples from your previous experience that demonstrate your skills in these areas. For instance, you could discuss a time when you successfully planned and scheduled a complex production run, or resolved a customer issue effectively.

3. Highlight Relevant Skills and Experience

Emphasize your experience in production planning, inventory management, quality control, and customer service. Quantify your achievements whenever possible using specific metrics, such as reducing production lead times or improving customer satisfaction ratings.

4. Research the Company

Familiarize yourself with the company’s industry, products, and services. Knowing the company’s background will help you understand their business needs and show that you have a genuine interest in the role.

5. Practice Your Answers

Rehearse your answers to common interview questions aloud. This will help you become more confident and articulate during the actual interview.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive at the interview on time to demonstrate your professionalism and respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Control Coordinating Clerk interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!