Are you gearing up for a career in Production Control Manager? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Production Control Manager and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

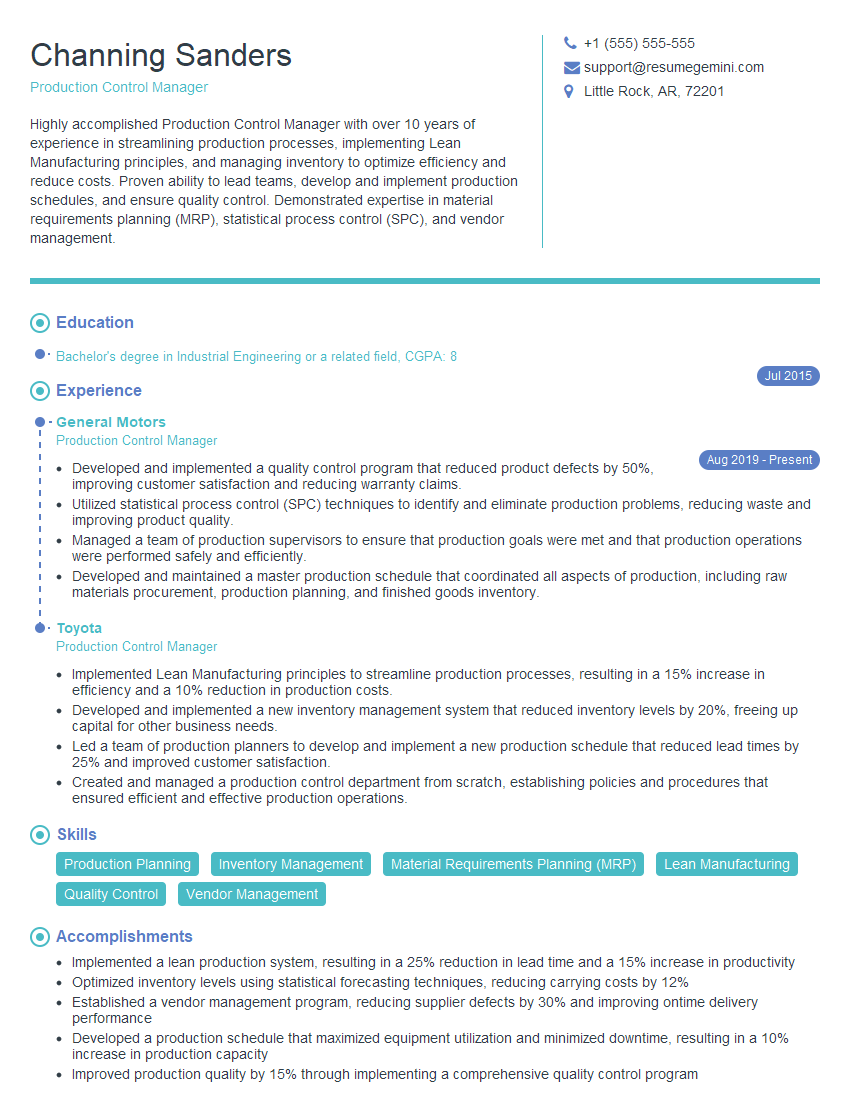

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Control Manager

1. How do you ensure that production schedules are met and that orders are completed on time?

To ensure that production schedules are met and that orders are completed on time, I employ the following strategies:

- Establish realistic schedules: Developing realistic schedules that account for factors such as machine capacity, material availability, and labor productivity is crucial.

- Monitor production progress: Regularly tracking production progress and identifying potential bottlenecks allows for timely adjustments and corrective actions.

- Communicate with stakeholders: Open communication with production teams, suppliers, and customers is essential to address any issues or changes that may impact schedules.

- Implement contingency plans: Having backup plans and alternative resources in place can help mitigate delays caused by unexpected events.

2. What techniques do you use to optimize production processes and improve efficiency?

Lean Manufacturing Principles

- Eliminate waste: Identify and eliminate non-value-added activities to streamline processes.

- Continuous improvement: Implement kaizen initiatives to encourage ongoing process improvements.

- Visual management: Use visual aids like Kanban boards to track progress and identify areas for optimization.

Technology and Automation

- Deploy automated systems: Leverage automation for repetitive tasks to improve accuracy and efficiency.

- Implement real-time data collection: Use sensors and data analytics to monitor production in real-time and identify inefficiencies.

3. How do you handle quality control and ensure that products meet customer specifications?

- Establish quality standards: Clearly define product specifications and adherence criteria.

- Implement quality control measures: Conduct inspections at various stages of production to identify and address defects.

- Empower employees: Engage production team members in quality control efforts to foster ownership and accountability.

- Conduct root cause analysis: Investigate quality issues to identify underlying causes and implement corrective actions.

- Seek customer feedback: Regularly collect and analyze customer feedback to identify areas for quality improvement.

4. What inventory management techniques do you use to optimize inventory levels and minimize costs?

- Implement Just-in-Time (JIT) inventory: Reduce inventory holding costs by receiving materials and components only when needed.

- Employ inventory optimization software: Utilize tools to forecast demand, set optimal inventory levels, and generate purchase orders.

- Establish safety stock levels: Determine appropriate buffer stock levels to minimize the risk of stockouts.

- Conduct regular inventory audits: Verify inventory accuracy and identify potential shrinkage or overstock.

- Collaborate with suppliers: Foster strong relationships with suppliers to ensure timely delivery and quality.

5. How do you manage production capacity and ensure that resources are utilized effectively?

- Forecast demand: Utilize historical data and market trends to forecast future demand and adjust capacity accordingly.

- Load leveling: Distribute workload evenly across production lines to minimize idle time and optimize resource utilization.

- Optimize production schedules: Create efficient schedules that consider factors such as batch sizes, machine availability, and material lead times.

- Implement flexible production systems: Utilize equipment and processes that can adapt to changing demand and product specifications.

- Collaborate with other departments: Coordinate with sales, engineering, and procurement to ensure alignment and efficient resource allocation.

6. How do you measure and evaluate production performance and identify areas for improvement?

- Establish performance metrics: Define key performance indicators (KPIs) such as production output, quality, efficiency, and cost.

- Collect and analyze data: Gather data through production reports, quality inspections, and customer feedback.

- Identify trends and deviations: Analyze data to identify trends, bottlenecks, and areas for improvement.

- Implement corrective actions: Develop and execute plans to address identified performance gaps.

- Continuous improvement: Regularly review and adjust performance measurement systems to enhance effectiveness.

7. How do you motivate and lead a team of production employees to achieve high performance?

- Communicate clear expectations: Establish clear goals, roles, and responsibilities for team members.

- Foster a positive work environment: Create a supportive and empowering atmosphere where employees feel valued.

- Provide training and development opportunities: Invest in training and development to enhance employee skills and knowledge.

- Recognize and reward achievements: Acknowledge and celebrate employee successes to boost morale and motivation.

- Empower team members: Delegate responsibilities and provide autonomy to employees to encourage ownership and accountability.

8. How do you stay updated on the latest trends and technologies in production management?

- Attend industry conferences and workshops: Participate in events to learn about new technologies and best practices.

- Read industry publications and blogs: Stay informed through magazines, websites, and online forums.

- Network with professionals: Connect with other production managers and experts to share knowledge and insights.

- Seek certifications and professional development: Enhance credibility and stay abreast of industry standards through certifications and training programs.

- Experiment with new technologies: Explore and evaluate emerging technologies to identify potential benefits and applications.

9. How do you handle production emergencies and minimize their impact on operations?

- Establish emergency response plans: Develop clear protocols for handling emergencies such as equipment breakdowns, power outages, and quality issues.

- Train employees on emergency procedures: Ensure that all employees are trained on emergency response plans and their roles and responsibilities.

- Identify and prioritize critical tasks: Determine which production activities are most essential and focus on maintaining those during emergencies.

- Communicate with stakeholders: Inform customers, suppliers, and management about the emergency and any potential impacts on orders or deliveries.

- Document and review emergency incidents: Analyze emergency events to identify areas for improvement and prevent recurrence.

10. How do you ensure that production aligns with the overall business strategy and goals?

- Collaborate with senior management: Regularly communicate with senior management to understand business objectives and align production activities accordingly.

- Translate business goals into production metrics: Establish clear production targets that support the overall business strategy, such as cost reduction or revenue growth.

- Monitor production performance against business goals: Track key production metrics and make adjustments as needed to ensure alignment with business objectives.

- Communicate production performance to senior management: Regularly report on production performance and its contribution to achieving business goals.

- Support product development and innovation: Collaborate with product development teams to ensure that production capabilities meet market demands and support product innovation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Control Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Control Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Production Control Manager is in charge of managing the processes and resources involved in the production of goods and services. They are responsible for ensuring that production is efficient, cost-effective, and meets customer requirements.

1. Planning and Scheduling

Production Control Managers are in charge of planning and scheduling the production process. They need to determine the resources and materials needed for production, as well as the timeline for each stage of the process.

- Developing production plans and schedules

- Identifying and sourcing materials and resources

- Allocating resources and assigning tasks

- Monitoring progress and making adjustments as needed

2. Maintaining Inventory

Production Control Managers are also responsible for maintaining inventory levels. They need to ensure that there is enough inventory to meet production needs, but they also need to avoid overstocking.

- Establishing and maintaining inventory levels

- Monitoring inventory levels and identifying potential issues

- Coordinating with suppliers and vendors

- Implementing inventory control systems

3. Quality Control

Production Control Managers are responsible for ensuring that the products or services meet quality standards. They need to establish and implement quality control procedures, and they need to monitor production to ensure that these procedures are followed.

- Developing and implementing quality control procedures

- Monitoring production processes and products

- Identifying and correcting quality issues

- Maintaining quality records

4. Cost Control

Production Control Managers are responsible for controlling production costs. They need to identify opportunities for cost reduction and they need to implement measures to reduce costs.

- Identifying and analyzing production costs

- Developing and implementing cost-reduction measures

- Monitoring production costs and identifying areas for improvement

- Reporting on production costs and cost-reduction initiatives

Interview Tips

Preparing for an interview for a Production Control Manager position can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview:

1. Do your research

Before you go into your interview, take some time to research the company and the position. This will help you understand the company’s culture and what they are looking for in a Production Control Manager.

- Visit the company’s website

- Read the job description carefully

- Look up the company on social media

2. Practice your answers

Once you have done your research, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Use the STAR method to answer questions

- Focus on your skills and experience

- Be clear and concise

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in production control. Be prepared to talk about your successes and failures, and how you have learned from your experiences.

- Use specific examples to demonstrate your skills

- Quantify your results whenever possible

- Be honest about your weaknesses

4. Ask questions

Asking questions shows the interviewer that you are interested in the position and that you are engaged in the interview process. It also gives you a chance to learn more about the company and the position.

- Ask about the company’s culture

- Ask about the company’s goals for the future

- Ask about the position’s responsibilities

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Control Manager interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!