Are you gearing up for an interview for a Production Counter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Production Counter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

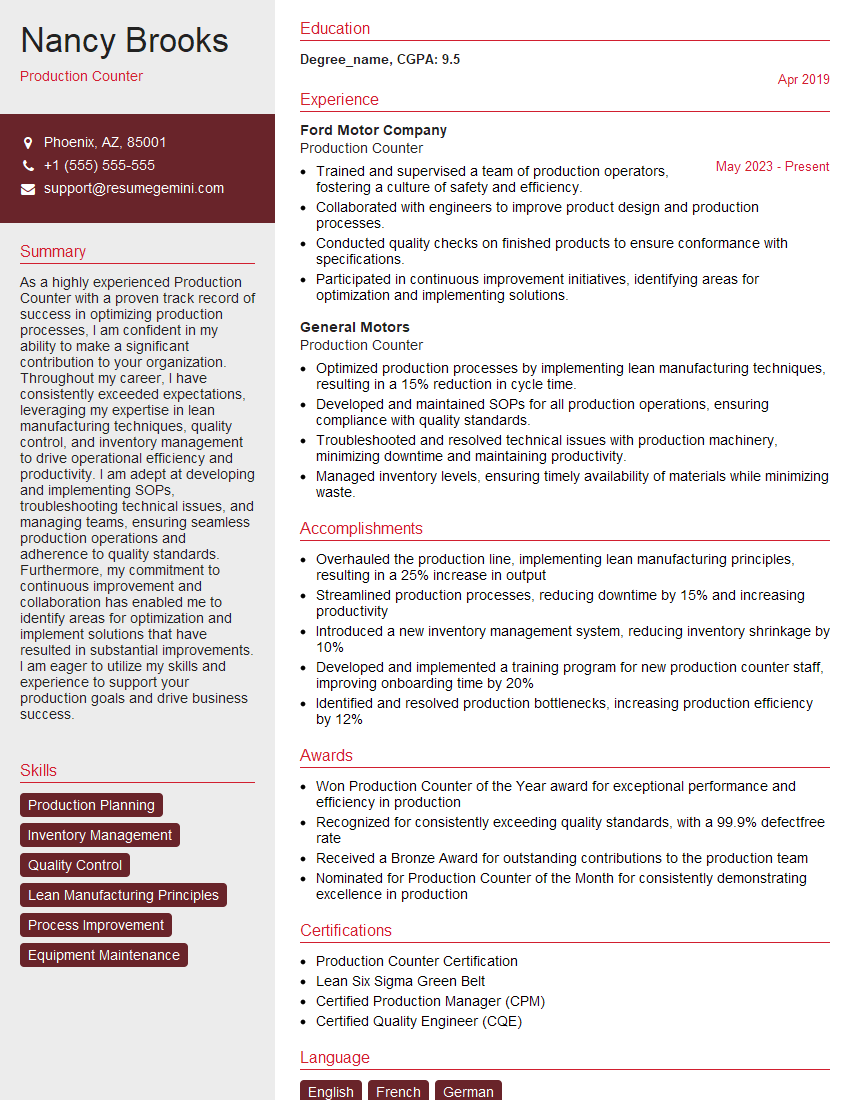

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Counter

1. Explain the process of receiving and inspecting raw materials at the production counter?

The process of receiving and inspecting raw materials at the production counter involves the following steps:

- Receiving the raw materials from suppliers and ensuring the delivery matches the purchase order.

- Conducting a thorough inspection of the raw materials to check for quality, quantity, and any potential defects or damages.

- Verifying the materials against the specifications, purchase orders, and quality standards.

- Documenting the inspection results and any discrepancies found.

- Storing the inspected raw materials in designated areas to maintain their quality and prevent spoilage.

2. Describe the procedures for maintaining accurate production records and tracking inventory levels.

- Utilizing a robust inventory management system to track the movement and quantities of all raw materials and finished goods.

- Regularly updating the inventory records to reflect the receipt of new materials, consumption during production, and shipment of finished products.

- Conducting periodic inventory audits to ensure the accuracy of the records and to identify any discrepancies or shrinkage.

- Maintaining a clear and organized system for tracking production orders, work-in-progress, and completed products.

- Providing timely and accurate reports on inventory levels, production output, and resource utilization.

3. Explain the importance of following standard operating procedures (SOPs) in the production process.

Adhering to SOPs in the production process is crucial for various reasons, including:

- Ensuring consistency and quality in product manufacturing by providing clear instructions and guidelines for all production tasks.

- Promoting safety in the workplace by outlining safe work practices and minimizing the risk of accidents or injuries.

- Facilitating knowledge transfer and training by providing a standardized reference for employees to follow.

- Improving efficiency and productivity by eliminating variations in production methods and reducing the need for rework.

- Maintaining compliance with industry regulations and quality standards, reducing the risk of non-conformance or product recalls.

4. Describe your experience in troubleshooting and resolving production issues.

- Identifying the root cause of production problems through systematic analysis and investigation.

- Implementing corrective actions to solve the issues efficiently and prevent recurrence.

- Documenting the troubleshooting process and solutions for future reference and continuous improvement.

- Collaborating with team members, supervisors, and engineers to find comprehensive solutions.

- Staying up-to-date on new technologies and industry best practices for resolving production challenges.

5. Explain the role of production counters in ensuring product quality.

- Performing thorough inspections of raw materials, in-process products, and finished goods to identify any defects or non-conformances.

- Monitoring production processes to ensure compliance with quality standards and specifications.

- Maintaining accurate quality records and documentation, including inspection reports and test results.

- Participating in quality improvement initiatives and suggesting measures to enhance product quality.

- Communicating quality issues to relevant personnel, including supervisors, engineers, and customers.

6. Describe your experience in managing multiple production lines simultaneously.

- Coordinating and overseeing multiple production lines to ensure efficient operations and meet production targets.

- Monitoring production progress, identifying bottlenecks, and adjusting schedules to optimize output.

- Allocating resources effectively across different production lines to maximize capacity utilization.

- Communicating with operators, supervisors, and other departments to ensure smooth coordination and resolve any issues.

- Maintaining a safe and organized work environment on all production lines.

7. Explain the importance of workplace safety in a production environment.

Workplace safety in a production environment is paramount for several reasons:

- Protecting the health and well-being of employees by minimizing the risk of accidents, injuries, and occupational hazards.

- Ensuring compliance with safety regulations and industry standards to avoid legal liabilities and penalties.

- Creating a positive and productive work environment where employees feel safe and motivated.

- Preventing production delays and disruptions caused by accidents or injuries.

- Maintaining a good reputation for the company as a responsible and safety-conscious organization.

8. Describe your experience in working with automated production equipment.

- Operating and maintaining automated machines, including robots, CNC machines, and assembly lines.

- Understanding the principles of automation and programming logic controllers (PLCs).

- Troubleshooting and resolving technical issues with automated equipment.

- Performing routine maintenance and calibration to ensure optimal performance.

- Collaborating with engineers and technicians to implement new automation technologies.

9. Explain the principles of lean manufacturing and how they can be applied to production processes.

- Understanding the principles of waste reduction, continuous improvement, and value-added activities.

- Identifying and eliminating waste in production processes, such as overproduction, inventory, defects, and waiting time.

- Streamlining production processes to improve efficiency, reduce cycle times, and enhance quality.

- Implementing lean tools and techniques, such as 5S, Kanban, and value stream mapping.

- Continuously monitoring and evaluating production processes to identify areas for further improvement.

10. Describe your communication and interpersonal skills in a production environment.

- Communicating effectively with operators, supervisors, engineers, and other departments to ensure smooth production operations.

- Providing clear instructions and updates on production status to all relevant personnel.

- Collaborating with team members to solve problems, share knowledge, and support each other.

- Building positive relationships with colleagues and maintaining a respectful and professional work environment.

- Adapting communication styles to different audiences and situations, both in person and through written communication.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Counter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Counter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Counters play a crucial role in ensuring efficient and accurate production processes within manufacturing environments.

1. Production Monitoring and Counting

Accurately count and verify the quantity of produced items to maintain production targets and inventory control.

- Utilize counting devices such as scales, counters, or manual counting methods to ensure precision.

- Maintain detailed records of production counts for tracking and analysis.

2. Quality Control and Inspection

Inspect produced items for defects, non-conformities, or deviations from specifications.

- Utilize established quality control procedures and checklists to identify and report irregularities.

- Collaborate with quality assurance teams to investigate and resolve quality issues.

3. Data Entry and Reporting

Enter production data into computerized systems or manual records for tracking and reporting purposes.

- Maintain accurate and timely records of production counts, quality checks, and other relevant information.

- Generate reports and summaries to provide data for production analysis and decision-making.

4. Equipment Maintenance and Calibration

Perform routine maintenance and calibration of production equipment to ensure optimal performance.

- Clean and inspect equipment to identify wear and tear or potential issues.

- Follow standard operating procedures (SOPs) for calibration to maintain equipment accuracy.

Interview Preparation Tips

To enhance your performance in a Production Counter interview, consider these preparation tips:

1. Research the Company and Industry

Thoroughly research the company you’re applying to and the industry it operates in.

- Visit the company’s website to gather information about their products, services, and company culture.

- Read industry publications and news articles to stay abreast of current trends and challenges.

2. Practice Common Interview Questions

Prepare for common interview questions by researching online resources and practicing your answers.

- Anticipate questions related to your production counting experience, quality control procedures, and data management skills.

- Consider using the STAR method (Situation, Task, Action, Result) to frame your answers and demonstrate your abilities.

3. Highlight Your Skills and Experience

Tailor your resume and cover letter to emphasize skills and experience that are relevant to the production counter role.

- Quantify your accomplishments using specific metrics whenever possible.

- Use action verbs and industry-specific terminology to demonstrate your proficiency.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions to ask the interviewer shows your engagement and interest in the role.

- Ask about the production processes, quality standards, and team dynamics.

- Inquire about opportunities for professional development and advancement within the company.

Next Step:

Now that you’re armed with the knowledge of Production Counter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Production Counter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini