Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Dispatcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

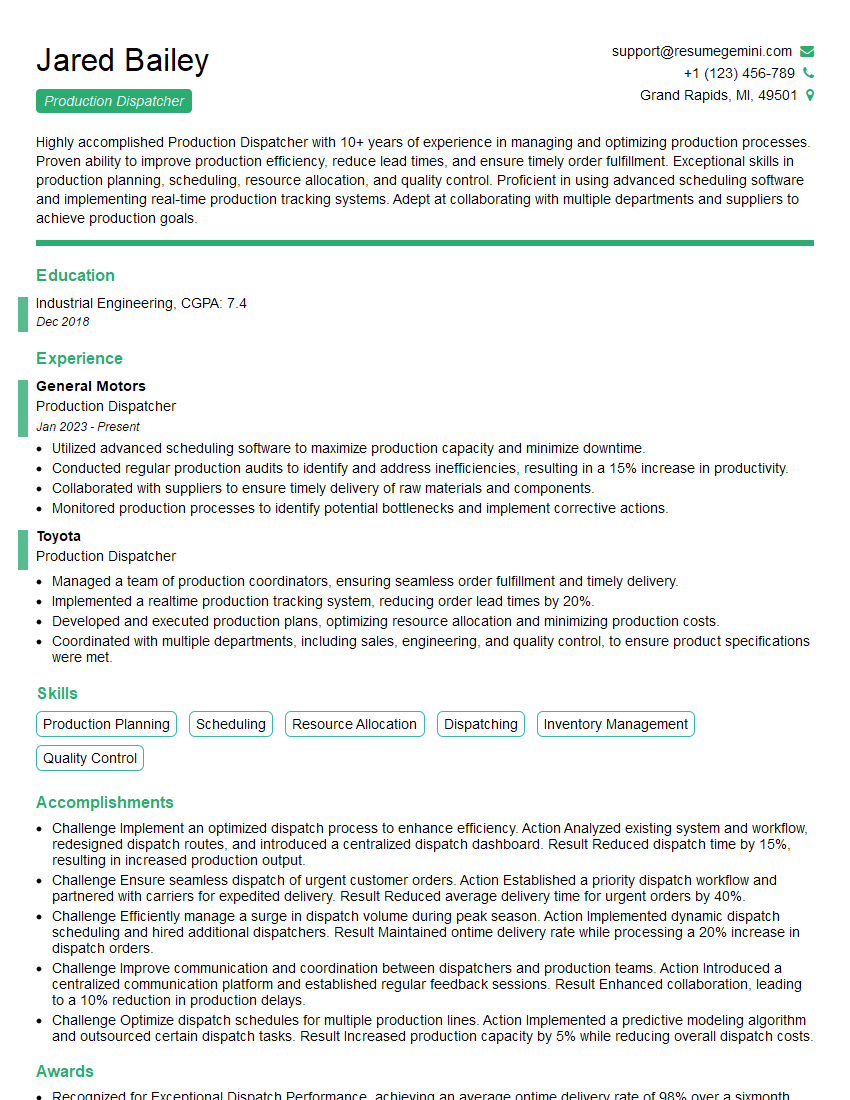

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Dispatcher

1. What is the role of a Production Dispatcher?

- Oversee and coordinate production activities to ensure timely and efficient delivery of products

- Monitor production schedules, identify potential bottlenecks, and take corrective actions to minimize delays

- Manage and allocate resources, including personnel, equipment, and materials, to optimize production flow

- Track and communicate production data, including inventory levels, production outputs, and quality control metrics

- Collaborate with other departments, such as sales, engineering, and purchasing, to ensure alignment of production activities with business objectives

2. How do you prioritize and manage multiple production tasks simultaneously?

Time Management Techniques

- Use task lists and prioritization methods (e.g., Eisenhower Matrix)

- Break down complex tasks into smaller, manageable units

- Delegate responsibilities to team members and monitor their progress

Communication and Coordination

- Establish clear communication channels with team members and stakeholders

- Regularly update on task progress and identify potential obstacles

- Hold team meetings to discuss priorities and coordinate efforts

3. How do you handle equipment failures or production delays?

- Assess the situation and identify the root cause of the failure or delay

- Develop a plan to address the issue and mitigate any potential consequences

- Implement corrective actions promptly to restore production operations as soon as possible

- Communicate the issue and the expected resolution timeline to relevant stakeholders

- Document the incident for future reference and improvement purposes

4. What software or tools do you use for production scheduling and monitoring?

- Enterprise Resource Planning (ERP) systems

- Manufacturing Execution Systems (MES)

- Production Planning and Scheduling software

- Data visualization tools (e.g., dashboards, reports)

5. How do you ensure that the production process meets quality standards?

- Implement quality control procedures and inspections at different stages of production

- Collaborate with quality assurance personnel to identify and address potential quality issues

- Provide regular training to production staff on quality standards and best practices

- Review and analyze production data to identify trends and areas for improvement

- Use Six Sigma or other quality improvement methodologies to enhance process efficiency and reduce defects

6. How do you manage inventory levels to avoid shortages or overstocking?

- Monitor inventory levels regularly and forecast future demand

- Implement inventory control systems (e.g., Just-in-Time Inventory)

- Collaborate with the purchasing department to ensure timely replenishment of materials

- Optimize inventory storage and handling processes to minimize waste and damage

7. How do you handle customer orders and ensure timely delivery?

- Receive and process customer orders accurately and promptly

- Coordinate with production and shipping departments to plan and execute delivery schedules

- Track order status and provide updates to customers as needed

- Resolve any issues related to order fulfillment efficiently

8. What safety protocols do you follow in a production environment?

- Adhere to established safety regulations and procedures

- Wear appropriate personal protective equipment (PPE)

- Identify and mitigate potential hazards in the work area

- Report unsafe conditions or incidents promptly

- Participate in safety training programs and drills

9. How do you measure and improve the efficiency of production processes?

- Collect and analyze production data using key performance indicators (KPIs)

- Identify bottlenecks and areas for improvement

- Implement process improvement initiatives (e.g., Six Sigma, Lean Manufacturing)

- Regularly review and adjust production schedules to optimize efficiency

10. What are the key challenges you have faced as a Production Dispatcher and how did you overcome them?

Provide specific examples of challenges encountered, the steps taken to resolve them, and the outcomes achieved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Dispatcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Dispatcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Dispatchers are the backbone of manufacturing operations, ensuring that production runs smoothly and efficiently. Their key responsibilities include:

1. Production Planning and Scheduling

Collaborating with production managers to develop production plans and schedules.

- Allocating resources, such as materials, equipment, and labor.

- Monitoring production progress and making adjustments as needed.

2. Material Management

Ensuring that the right materials are available at the right time and place.

- Coordinating with suppliers and purchasing departments

- Tracking material inventory and initiating replenishment orders

3. Equipment Maintenance and Repair

Working with maintenance personnel to ensure that equipment is operating in optimal condition.

- Scheduling preventive maintenance and repairs

- Responding to equipment failures and minimizing downtime

4. Quality Control

Monitoring production processes to ensure that products meet quality standards.

- Inspecting products and identifying defects

- Initiating corrective actions and collaborating with quality control personnel

5. Customer Service

Interfacing with customers to provide product information and assist with order fulfillment.

- Answering customer inquiries and complaints

- Tracking orders and providing delivery information

Interview Tips

Preparing for a Production Dispatcher interview requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s operations, products, and industry landscape. This will demonstrate your interest and enthusiasm for the role.

2. Highlight Your Production Planning and Scheduling Skills

Provide specific examples of how you have successfully planned and scheduled production operations. Share metrics or outcomes that demonstrate the positive impact of your work.

3. Emphasize Your Material Management Expertise

Discuss your experience in coordinating with suppliers, managing inventory, and optimizing material flow. Highlight any initiatives you have led that improved material availability or reduced lead times.

4. Showcase Your Equipment Maintenance Knowledge

Demonstrate your understanding of equipment maintenance principles and your ability to work effectively with maintenance teams. Share examples of how you have proactively identified and resolved equipment issues.

5. Highlight Your Commitment to Quality

Express your passion for ensuring product quality. Provide examples of your attention to detail, your ability to identify and address defects, and your commitment to continuous improvement.

6. Showcase Your Customer Service Skills

Share experiences where you have effectively interacted with customers, resolved their queries, and provided excellent service. Highlight your communication skills, empathy, and ability to build relationships.

7. Prepare for Common Interview Questions

Research common interview questions for Production Dispatchers, such as “Describe your experience in production planning and scheduling” or “How do you handle equipment failures during production?” Prepare thoughtful and specific answers that demonstrate your expertise and capabilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Dispatcher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.