Are you gearing up for an interview for a Production Engineering Tooling Coordinator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Production Engineering Tooling Coordinator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

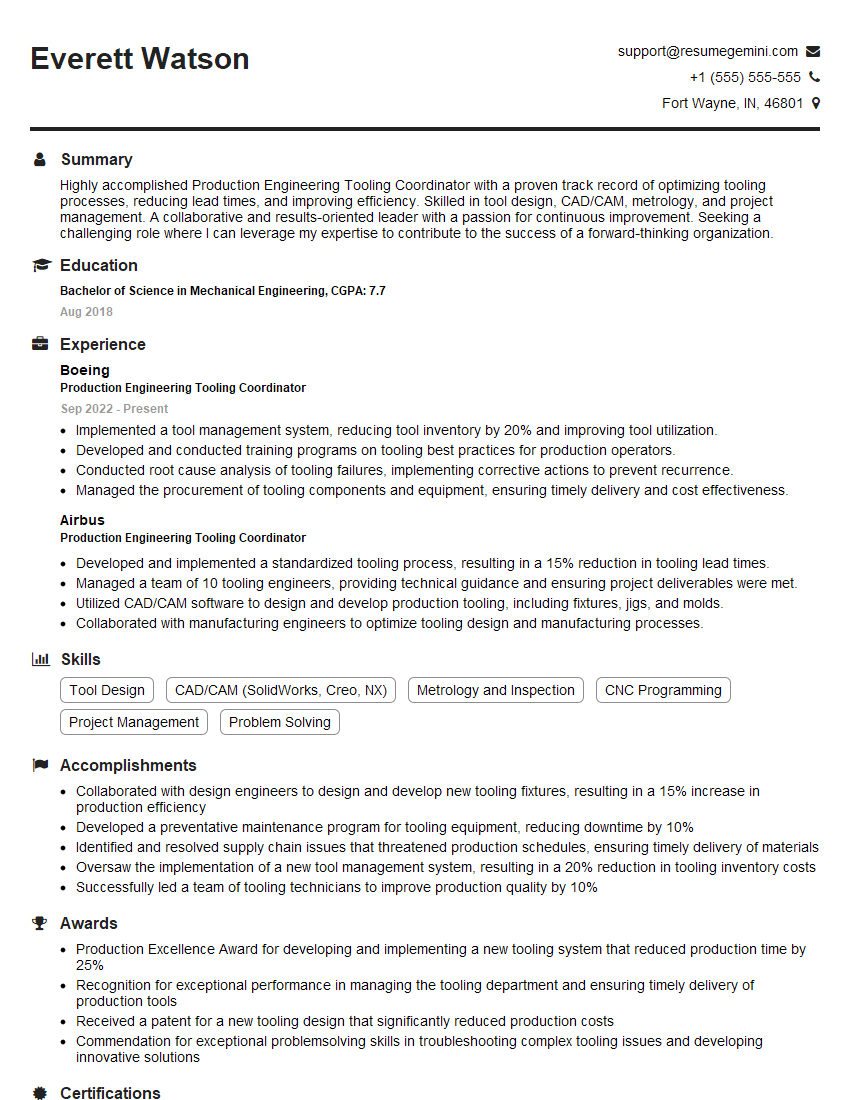

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Engineering Tooling Coordinator

1. What are the key responsibilities of a Production Engineering Tooling Coordinator?

As a Production Engineering Tooling Coordinator, my main responsibilities include:

- Coordinate the design, fabrication, and maintenance of production tooling, jigs, and fixtures.

- Develop and implement tooling processes and procedures to ensure efficient production.

2. What are the different types of tooling used in production engineering?

Types of tooling:

- Cutting tools

- Forming tools

- Jigs and fixtures

Specific examples:

- Milling cutters, drill bits, taps

- Dies, punches, molds

- Clamps, locators, workholding devices

3. How do you ensure the quality of tooling and maintain its performance?

I follow a comprehensive approach to ensure tooling quality and performance:

- Establish clear quality standards and specifications for tooling design and fabrication.

- Conduct regular inspections and maintenance to identify and address any issues early on.

- Implement a preventive maintenance program to minimize downtime and extend tooling life.

4. What are the factors to consider when designing tooling for a specific production process?

When designing tooling, I consider several critical factors:

- Material properties and workpiece geometry.

- Production volume and cycle time requirements.

- Accuracy and precision specifications.

- Cost and availability of materials and manufacturing processes.

5. How do you stay up-to-date with the latest tooling technologies and best practices?

To stay current with industry advancements, I engage in continuous learning:

- Attend industry conferences, workshops, and training programs.

- Read technical publications, journals, and articles.

- Collaborate with tooling suppliers and industry experts.

6. How do you manage relationships with vendors and suppliers of tooling components?

I foster strong relationships with vendors and suppliers to ensure:

- Reliable supply chain for critical tooling components.

- Competitive pricing and timely delivery.

- Technical support and collaboration on tooling design and optimization.

7. What software tools do you use for tooling design and analysis?

- Computer-aided design (CAD) software for 3D modeling and drawing creation.

- Finite element analysis (FEA) software for simulating tooling performance and identifying potential issues.

- Tool management software for tracking tooling inventory, usage, and maintenance schedules.

8. How do you optimize tooling for maximum productivity and efficiency?

Optimization techniques:

- Tool selection based on material properties and cutting conditions.

- Tool geometry design for improved chip removal and reduced cutting forces.

- Proper tooling setup and alignment for precision and accuracy.

9. How do you handle tooling issues that arise during production?

When tooling issues occur, I follow a structured approach:

- Identify the problem and its root cause.

- Develop and implement a solution to resolve the issue.

- Document the solution and implement preventive measures to minimize future occurrences.

10. Describe a project where you successfully implemented a new tooling solution that improved production efficiency.

In a previous role, I led a project to implement a new cutting tool and holder system. By optimizing tool geometry and cutting parameters, we:

- Increased cutting speed by 25%, reducing cycle time.

- Improved surface finish and dimensional accuracy.

- Extended tool life by 30%, reducing downtime and costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Engineering Tooling Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Engineering Tooling Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Production Engineering Tooling Coordinator is responsible for coordination and implementation of tooling programs within the production environment.

1. Tooling Design and Development

Collaborate with design engineers to develop and implement tooling solutions for production processes.

- Review engineering drawings and specifications to assess tooling requirements.

- Design and develop jigs, fixtures, dies, and other tooling components.

2. Tooling Procurement and Management

Manage the procurement and inventory of tooling components.

- Source and negotiate with suppliers for tooling materials and equipment.

- Maintain inventory levels and ensure timely delivery of tooling.

3. Tooling Maintenance and Repair

Supervise the maintenance and repair of tooling components.

- Develop and implement maintenance schedules for tooling.

- Inspect and repair tooling components as needed.

4. Production Support

Provide technical support to production staff on tooling-related issues.

- Troubleshoot production problems related to tooling.

- Train production staff on the use and maintenance of tooling.

Interview Preparation Tips

Interviews can be nerve-wracking, but preparation can boost confidence. Here are some tips to help you ace your Production Engineering Tooling Coordinator interview:

1. Research the Company and Position

Thoroughly research the company, its products or services, and the specific role you’re applying for. This shows the interviewer that you’re genuinely interested in the position and the company.

- Visit the company website and read about their mission, values, and recent news.

- Look for the job description on the company’s website or on job boards. Carefully review the responsibilities and qualifications to understand what the employer is looking for.

2. Practice Your Answers to Common Interview Questions

There are certain questions that are commonly asked in interviews, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions concisely and confidently.

- Use the STAR method to structure your answers: Situation, Task, Action, Result. This helps you provide clear and specific examples of your skills and experience.

- Focus on highlighting your relevant skills and experience, and how they align with the job requirements.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows the interviewer that you’re engaged and interested in the opportunity. It also gives you a chance to gather more information about the company and the position.

- Questions about the company’s culture, growth plans, and industry trends demonstrate your enthusiasm for the company and the role.

- Questions about the specific responsibilities and expectations of the position will indicate your interest in the day-to-day aspects of the job.

4. Dress Professionally and Be On Time

First impressions matter, so make sure to dress professionally and arrive on time for your interview. This shows respect for the interviewer and the company.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Plan your route to the interview location in advance to avoid any delays.

5. Be Enthusiastic and Confident

Interviewers are looking for candidates who are excited about the opportunity and confident in their abilities. Display your passion for the field and your interest in the position throughout the interview.

- Smile, make eye contact, and speak clearly and confidently.

- Emphasize your skills and experience, and explain how you can contribute to the company.

6. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer. This shows your appreciation for their time and consideration. You can also reiterate your interest in the position and mention any additional information you may have forgotten to share during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Engineering Tooling Coordinator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!