Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Production Gear Cutting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Production Gear Cutting Machine Operator so you can tailor your answers to impress potential employers.

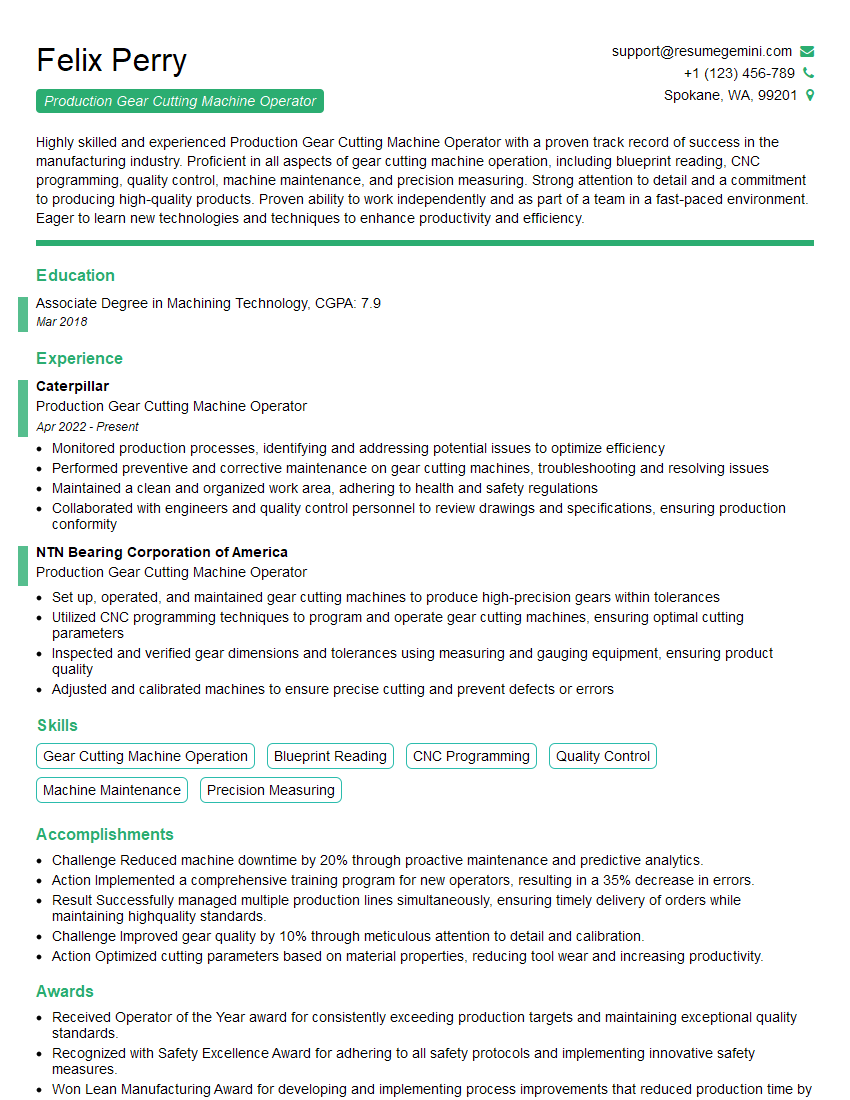

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Gear Cutting Machine Operator

1. Explain the safety precautions you take when operating a production gear cutting machine?

- Always wear appropriate safety gear, including eye protection, earplugs, and gloves.

- Be aware of the machine’s surroundings and keep clear of moving parts.

- Never operate the machine under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions for the safe operation of the machine.

- Report any unsafe conditions to your supervisor immediately.

2. What are the different types of gear cutting machines and their applications?

Types of Gear Cutting Machines

- Hobbing machines use a hob to cut gears.

- Shaping machines use a shaper to cut gears.

- Milling machines use a milling cutter to cut gears.

- Broaching machines use a broach to cut gears.

- Grinding machines use a grinding wheel to cut gears.

Applications of Gear Cutting Machines

- Hobbing machines are used to cut spur gears, helical gears, and worm gears.

- Shaping machines are used to cut spur gears and helical gears.

- Milling machines are used to cut spur gears, helical gears, bevel gears, and worm gears.

- Broaching machines are used to cut internal gears.

- Grinding machines are used to finish gears and to cut gears with a high degree of precision.

3. How do you set up and operate a production gear cutting machine?

- Mount the workpiece on the machine table.

- Select the appropriate cutting tool.

- Set the machine’s speed and feed rate.

- Start the machine and monitor the cutting process.

- Stop the machine when the cutting process is complete.

4. How do you maintain a production gear cutting machine?

- Clean the machine regularly.

- Lubricate the machine’s moving parts.

- Inspect the machine’s cutting tools for wear and tear.

- Calibrate the machine regularly.

- Follow the manufacturer’s instructions for maintenance.

5. How do you troubleshoot common problems with a production gear cutting machine?

- If the machine is not cutting properly, check the cutting tool for wear and tear.

- If the machine is making excessive noise, check the machine’s bearings for wear and tear.

- If the machine is vibrating excessively, check the machine’s foundation for stability.

- If the machine is not stopping properly, check the machine’s brakes for wear and tear.

- If the machine is not starting properly, check the machine’s electrical connections.

6. What are the different types of gear materials and their properties?

- Steel is the most common material used for gears.

- Stainless steel is a good choice for gears that are exposed to corrosive environments.

- Aluminum is a lightweight material that is often used for gears in applications where weight is a concern.

- Bronze is a good choice for gears that are exposed to high loads.

- Nylon is a lightweight material that is often used for gears in applications where noise is a concern.

7. How do you select the appropriate gear material for a specific application?

- Consider the load that the gear will be subjected to.

- Consider the environment in which the gear will be used.

- Consider the weight of the gear.

- Consider the cost of the gear material.

- Consider the availability of the gear material.

8. What are the different types of gear tooth profiles and their advantages and disadvantages?

- Spur gears have straight teeth.

- Helical gears have teeth that are cut at an angle to the axis of the gear.

- Bevel gears have teeth that are cut on a cone-shaped surface.

- Worm gears have a worm-shaped gear that meshes with a gear with teeth.

9. How do you calculate the gear ratio of a gear train?

- The gear ratio of a gear train is the ratio of the number of teeth on the driving gear to the number of teeth on the driven gear.

- For example, if the driving gear has 20 teeth and the driven gear has 40 teeth, the gear ratio is 20:40 or 1:2.

- The gear ratio of a gear train can be used to calculate the speed of the driven gear.

10. What are the different types of gear trains and their applications?

- Simple gear trains consist of two gears that are engaged directly with each other.

- Compound gear trains consist of two or more gears that are engaged with each other in a series.

- Planetary gear trains consist of a central gear that is engaged with two or more planet gears.

- Epicyclic gear trains consist of a central gear that is engaged with two or more planet gears and a ring gear.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Gear Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Gear Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Production Gear Cutting Machine Operator, you will play a pivotal role in producing high-quality gears for various industrial applications. Your responsibilities will include:

1. Machine Operation and Maintenance

Setting up, operating, and monitoring production gear cutting machines to ensure optimal performance.

- Properly loading and securing raw materials.

- Selecting and installing appropriate tooling and fixtures.

- Adjusting machine parameters for specific production requirements.

2. Quality Control and Inspection

Conducting regular inspections and quality checks to verify the accuracy and quality of gears produced.

- Measuring and documenting dimensions using precision instruments.

- Observing gears for signs of defects or wear.

- Ensuring compliance with established quality standards.

3. Troubleshooting and Maintenance

Identifying and resolving any machine malfunctions or production issues.

- Diagnosing mechanical, electrical, or hydraulic problems.

- Performing repairs and preventive maintenance as needed.

4. Process Improvement and Productivity

Continuously improving production processes to enhance efficiency and output.

- Monitoring operational data to identify areas for optimization.

- Collaborating with colleagues to develop and implement process improvements.

Interview Tips

To prepare effectively for your Production Gear Cutting Machine Operator interview, consider the following tips:

1. Research the Company and Position

Thoroughly research the company’s website, industry reports, and any available information about the specific position.

- Understand the company’s products, services, and market position.

- Learn about the role’s specific responsibilities and requirements.

2. Practice Your Technical Skills

Review and practice the technical aspects of gear cutting, such as:

- Gear nomenclature and terminology.

- Machine operation and maintenance procedures.

- Quality control techniques and industry standards.

3. Highlight Your Experience and Skills

Clearly articulate your relevant experience in operating and maintaining production gear cutting machines.

- Quantify your accomplishments with specific examples and metrics.

- Emphasize your troubleshooting and problem-solving abilities.

4. Prepare for Behavioral Questions

Anticipate behavioral interview questions that assess your:

- Teamwork and collaboration skills.

- Attention to detail and commitment to quality.

- Problem-solving and decision-making abilities.

Next Step:

Now that you’re armed with the knowledge of Production Gear Cutting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Production Gear Cutting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini