Feeling lost in a sea of interview questions? Landed that dream interview for Production Hardener but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Production Hardener interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

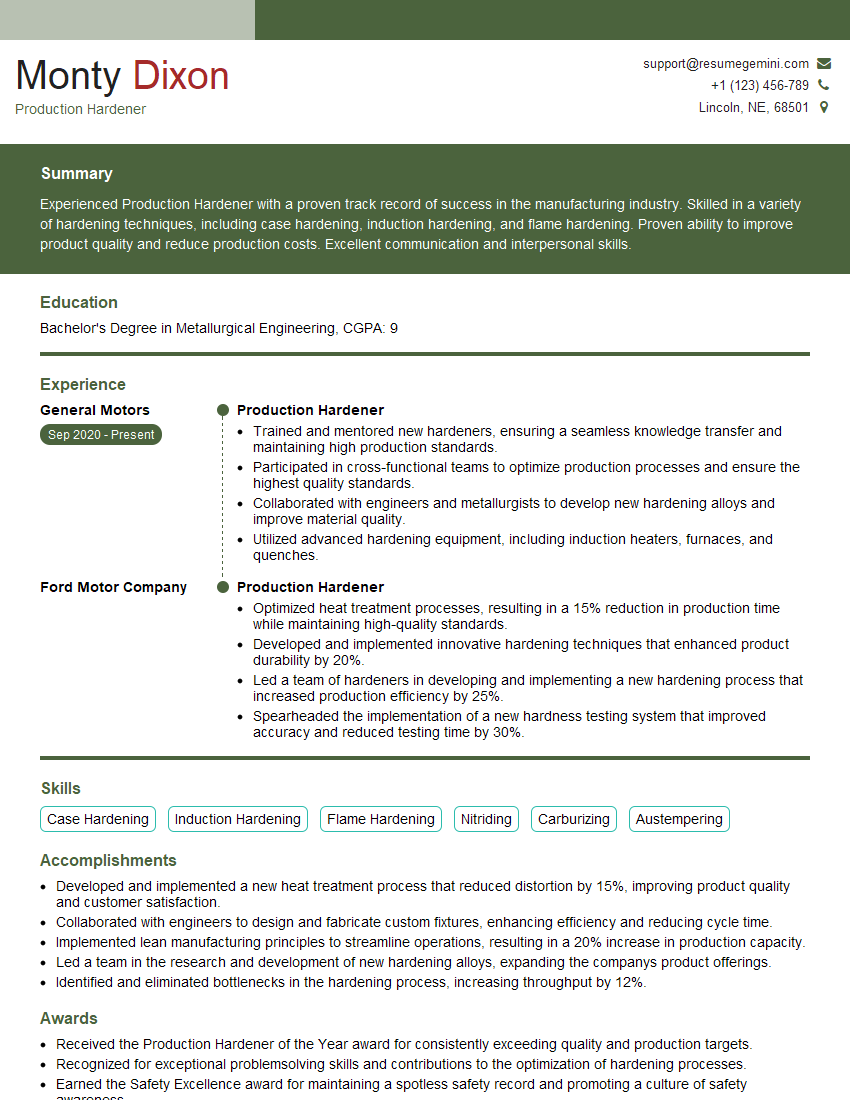

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Hardener

1. What are the different types of hardening processes and their applications?

Answer:

- Flame hardening: Used to harden the surface of steel components, providing wear and abrasion resistance.

- Induction hardening: Generates heat through induction, resulting in a hardened surface while maintaining a softer core.

- Carburizing: Diffuses carbon into the surface of steel, creating a hard and wear-resistant case.

- Nitriding: Diffuses nitrogen into the surface of steel, improving wear resistance and surface hardness.

2. Describe the steps involved in the flame hardening process.

Answer:

- Preheat: Heat the component to a specific temperature below the critical point.

- Heating: Focus a flame on the surface to be hardened, raising the temperature above the critical point.

- Quenching: Rapidly cool the heated surface using water or oil to increase hardness.

3. What are the advantages of induction hardening over flame hardening?

Answer:

- Selective hardening: Allows for precise hardening of specific areas.

- Minimal distortion: Induces less thermal stress, resulting in minimal warping or bending.

- Improved surface quality: Produces a fine-grained structure, improving wear resistance.

4. Explain the process of gas carburizing and its benefits.

Answer:

- Process: Exposes the component to a carbon-rich atmosphere, allowing carbon to diffuse into the surface.

- Benefits: Creates a hard and wear-resistant surface while maintaining a ductile core, improves fatigue strength, and reduces friction.

5. What are the different factors to consider when selecting a quenching medium?

Answer:

- Cooling rate: Determines the hardness and microstructure of the hardened surface.

- Quenching severity: Influences the risk of cracking or distortion.

- Safety: Some quenching media, such as oil, require precautions to avoid fire hazards.

6. Describe the tempering process and its effects on hardened steel.

Answer:

- Process: Reheating hardened steel to a specific temperature below the critical point and then cooling it slowly.

- Effects: Reduces brittleness, increases toughness, and relieves residual stresses, making the steel more suitable for practical applications.

7. What are the common defects associated with hardening processes and how can they be prevented?

Answer:

- Warpage or distortion: Can be prevented by ensuring uniform heating and cooling, and by using fixtures or supports.

- Cracking: Can be prevented by selecting an appropriate quenching medium and tempering the hardened steel.

- Soft spots: Can be prevented by thorough heating and ensuring proper quenching techniques.

8. How do you ensure the quality of hardened products?

Answer:

- Testing: Conduct hardness tests, microstructure analysis, and mechanical testing to verify properties.

- Process control: Implement rigorous quality control measures throughout the hardening process.

- Equipment calibration: Regularly calibrate equipment and maintain accurate temperature control.

9. Describe the safety precautions that should be taken when working with hardening equipment.

Answer:

- Protective gear: Wear appropriate PPE, including gloves, safety glasses, and protective clothing.

- Proper ventilation: Ensure adequate ventilation to avoid exposure to fumes or gases.

- Training: Ensure that all operators are trained and certified to operate equipment safely.

10. How do you stay up-to-date with the latest advancements in hardening technology?

Answer:

- Industry publications: Subscribe to magazines and journals dedicated to hardening processes.

- Workshops and conferences: Attend industry events to learn about new techniques and equipment.

- Online resources: Utilize online forums, technical articles, and webinars to stay informed.

- Collaboration: Network with other professionals in the field to share knowledge and experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Hardener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Hardener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Hardeners are responsible for the proper hardening and tempering of metal components. They work in a manufacturing environment and use specialized equipment to heat treat metals to the desired hardness and strength. The key job responsibilities of a Production Hardener include:

1. Preparing Metals for Hardening

Production Hardeners prepare metals for hardening by cleaning and inspecting them. They then determine the proper hardening temperature and time for the specific type of metal.

- Clean and inspect metal components to remove any dirt, oil, or other contaminants.

- Determine the proper hardening temperature and time for the specific type of metal.

2. Hardening Metals

Production Hardeners heat metals to the desired temperature in a furnace or oven. They then quench the metals in water, oil, or another cooling medium to harden them.

- Heat metals to the desired temperature in a furnace or oven.

- Quench the metals in water, oil, or another cooling medium to harden them.

3. Tempering Metals

Production Hardeners temper metals to reduce their hardness and increase their toughness. They do this by heating the metals to a lower temperature and then cooling them slowly.

- Heat metals to a lower temperature to temper them.

- Cool the metals slowly to increase their toughness.

4. Testing Metals

Production Hardeners test metals to ensure that they meet the desired hardness and strength specifications. They use a variety of testing methods, such as Rockwell hardness testing and tensile testing.

- Test metals to ensure that they meet the desired hardness and strength specifications.

- Use a variety of testing methods, such as Rockwell hardness testing and tensile testing.

Interview Tips

Here are some tips to help you ace your interview for a Production Hardener position:

1. Research the company and the position

Before your interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience that they are looking for in a Production Hardener.

- Visit the company’s website to learn about their history, products, and services.

- Read articles and reviews about the company to get an idea of their reputation in the industry.

- Use LinkedIn to connect with current and former employees of the company to get insights into the company culture and the specific position you are applying for.

2. Practice your answers to common interview questions

There are a number of common interview questions that you should be prepared to answer, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.” Practice answering these questions in advance so that you can deliver confident and well-thought-out responses.

- Use the STAR method to answer interview questions. The STAR method stands for Situation, Task, Action, Result. When answering an interview question, start by describing a specific situation that you were in. Then, explain the task that you had to complete in that situation. Next, describe the actions that you took to complete the task. Finally, explain the results of your actions.

3. Be prepared to talk about your experience

In your interview, you will be asked about your experience as a Production Hardener. Be prepared to talk about your specific skills and accomplishments, as well as your knowledge of the industry. Highlight your experience in preparing metals for hardening, hardening metals, tempering metals, and testing metals.

- Quantify your accomplishments whenever possible. For example, instead of saying “I hardened metals,” say “I hardened over 100,000 metal components per month.”.

- Use specific examples to illustrate your skills and experience. For example, instead of saying “I am a skilled metal tester,” say “I used Rockwell hardness testing and tensile testing to ensure that metal components met the desired hardness and strength specifications.”.

4. Be prepared to ask questions

At the end of your interview, you will be given an opportunity to ask questions. This is a great opportunity to learn more about the company and the position, as well as to show the interviewer that you are interested and engaged. Some good questions to ask include:

- What are the company’s goals for the future?

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Hardener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!