Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Honing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

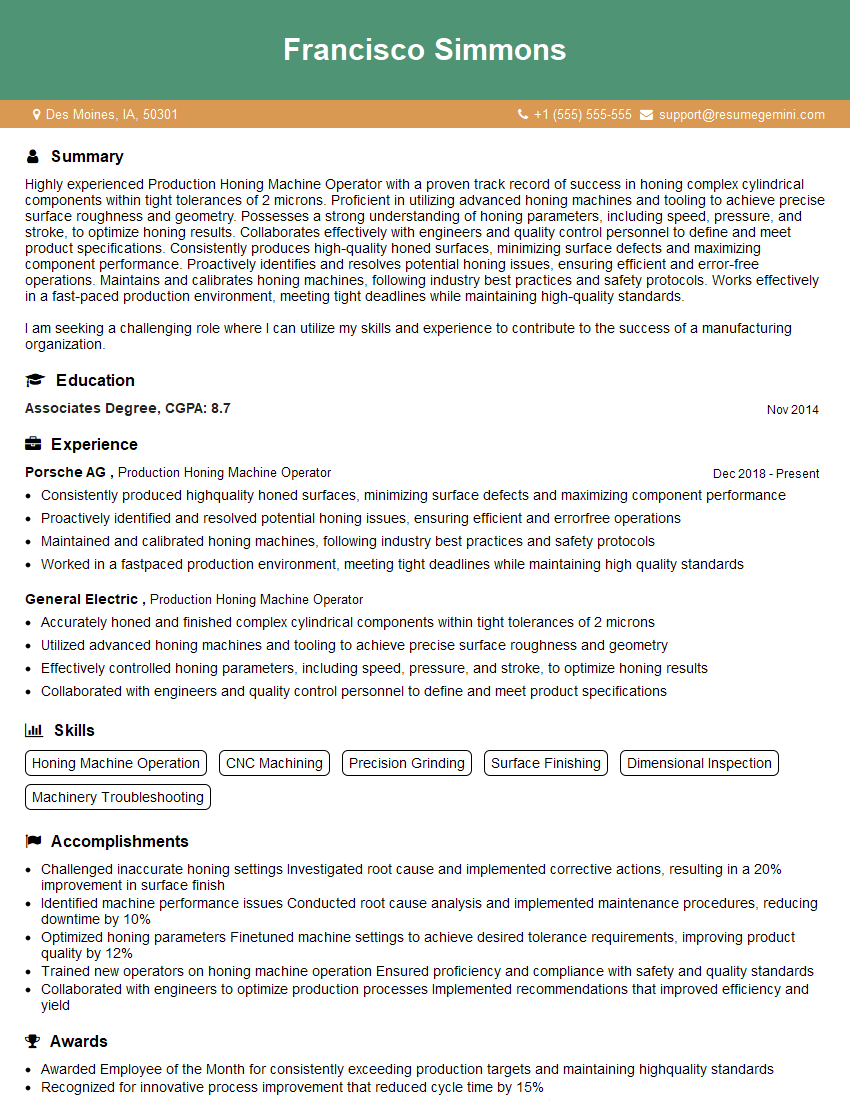

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Honing Machine Operator

1. What is the process of honing?

Honing is a precision machining process that uses a bonded abrasive stick to remove material from the surface of a workpiece. It is typically used to improve the surface finish, dimensional accuracy, and geometric form of a workpiece.

2. What are the different types of honing machines?

There are two main types of honing machines: vertical and horizontal. Vertical honing machines are used for honing long, slender workpieces, such as shafts and cylinders. Horizontal honing machines are used for honing shorter, thicker workpieces, such as gears and castings.

3. What are the key factors that affect the honing process?

- The type of abrasive stick

- The speed of the honing head

- The feed rate of the workpiece

- The dwell time

- The coolant

4. What are the typical tolerances that can be achieved with honing?

Honing can typically achieve tolerances of +/- 0.0001 inch (0.0025 mm) for diameter and +/- 0.0002 inch (0.0051 mm) for length.

5. What are the advantages of honing?

- Improved surface finish

- Increased dimensional accuracy

- Improved geometric form

- Reduced friction and wear

- Increased load-carrying capacity

6. What are the disadvantages of honing?

- Can be a slow process

- Can be expensive

- Requires skilled operators

7. What are the different types of abrasive sticks used in honing?

- Diamond

- CBN

- Aluminum oxide

- Silicon carbide

8. What are the different coolants used in honing?

- Water-soluble oil

- Synthetic coolant

- Mineral oil

9. What are the safety precautions that must be taken when operating a honing machine?

- Wear eye protection

- Wear gloves

- Be aware of pinch points

- Do not operate the machine if it is not properly guarded

10. What is the difference between honing and lapping?

Honing is a more aggressive process than lapping. Honing uses a bonded abrasive stick to remove material from the surface of a workpiece, while lapping uses a loose abrasive to polish the surface of a workpiece. Honing is typically used to improve the surface finish, dimensional accuracy, and geometric form of a workpiece, while lapping is typically used to improve the surface finish of a workpiece.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Honing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Honing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Production Honing Machine Operator plays a crucial role in the manufacturing process. Their primary duties revolve around operating honing machines to refine the surfaces of various metal components. This demanding role demands a combination of technical expertise, precision, and quality consciousness.

1. Machine Operation and Maintenance

Efficiently operates honing machines to remove material, improve surface finish, and achieve the desired dimensions of components.

- Sets up and configures honing machines according to specifications.

- Monitors and adjusts machine parameters, such as spindle speed, feed rate, and abrasive pressure.

- Inspects and maintains honing machines to ensure optimal performance and safety.

2. Quality Control and Inspection

Ensures that honed components meet specified tolerances and quality standards.

- Conducts visual and dimensional inspections using precision measuring tools.

- Identifies and corrects deviations from specifications to maintain high product quality.

- Records inspection results and maintains quality control documentation.

3. Production Monitoring and Reporting

Contributes to production efficiency and productivity.

- Monitors production schedules and adjusts machine settings to optimize output.

- Identifies and reports any production issues or bottlenecks promptly.

- Participates in continuous improvement initiatives to enhance efficiency and reduce waste.

4. Safety and Compliance

Adheres to established safety regulations and procedures to ensure a safe work environment.

- Follows proper machine operation protocols and wears appropriate safety gear.

- Maintains a clean and organized work area to prevent accidents.

- Participates in safety training and refresher courses regularly.

Interview Tips

Preparing for an interview for a Production Honing Machine Operator position requires a blend of technical knowledge, research, and effective communication skills. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company’s history, culture, and the specific requirements of the Production Honing Machine Operator role. This will demonstrate your interest in the opportunity and your understanding of the industry.

- Visit the company’s website to learn about their products, services, and values.

- Check industry publications and online forums to gather insights into the company’s reputation and market standing.

- Review the job description and identify the key responsibilities and qualifications required for the position.

2. Highlight Your Technical Expertise

Emphasize your technical skills and experience in operating honing machines. Provide specific examples of your ability to set up, configure, and maintain these machines effectively.

- Discuss your experience with different types of honing machines and the components you have worked on.

- Explain your understanding of honing parameters and how you optimize them to achieve desired results.

- Showcase your knowledge of quality control techniques and your ability to inspect honed components to ensure precision.

3. Demonstrate Your Problem-Solving Abilities

Production environments often encounter unexpected challenges. Highlight your problem-solving skills and how you have successfully overcome production issues in the past.

- Share examples of situations where you identified and resolved machine malfunctions or production bottlenecks.

- Explain your approach to troubleshooting and your ability to think critically to find solutions.

- Discuss your willingness to collaborate with colleagues and supervisors to address production challenges.

4. Communicate Clearly and Confidently

Effective communication is crucial in any workplace. Demonstrate your ability to communicate clearly and confidently during the interview. Articulate your thoughts and ideas in a concise and engaging manner.

- Practice answering common interview questions and prepare specific examples to support your responses.

- Be prepared to ask thoughtful questions about the company and the position to show your interest and enthusiasm.

- Maintain a professional and positive demeanor throughout the interview, showing respect for the interviewers’ time and expertise.

Next Step:

Now that you’re armed with the knowledge of Production Honing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Production Honing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini