Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Leader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

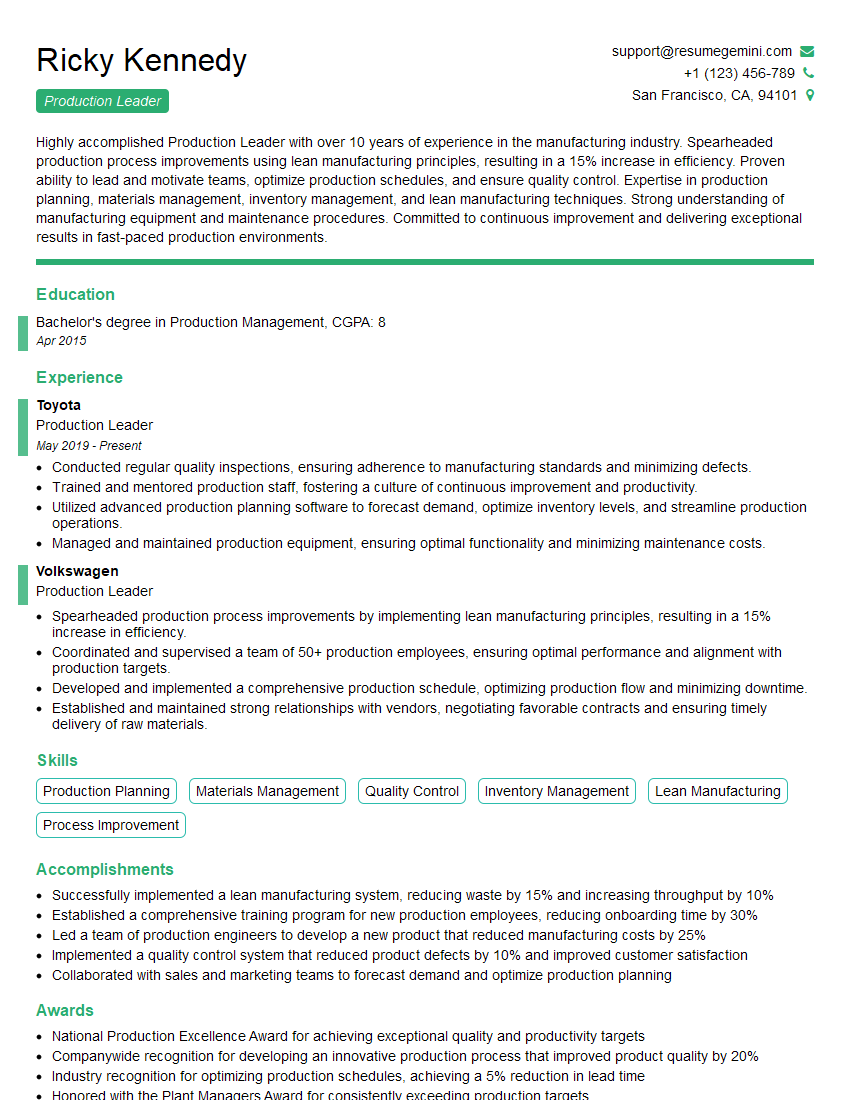

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Leader

1. What are the key performance indicators (KPIs) you would use to measure the success of a production team?

KPIs are used to measure and track a team’s performance. Some KPIs are used to gauge the production team’s efficiency and effectiveness.

- Overall Equipment Effectiveness (OEE)

- First Pass Yield (FPY)

- Throughput

- Downtime

- Quality

2. How would you improve the efficiency of a production process?

Reduce waste and improve flow

- Identify and eliminate waste in the production process to make it more efficient.

- Optimize the flow of materials and products through the production process to reduce bottlenecks.

Improve equipment utilization

- Ensure that equipment is properly maintained and calibrated to minimize downtime.

- Use preventive maintenance techniques to identify and fix potential problems before they cause major breakdowns.

Increase productivity

- Provide training to employees to improve their skills and knowledge.

- Implement incentives and rewards to motivate employees to improve their performance.

3. What are the different types of production scheduling techniques?

Here are some of the common production scheduling techniques:

- First-in, first-out (FIFO)

- Last-in, first-out (LIFO)

- Shortest job first (SJF)

- Longest job first (LJF)

- Critical path method (CPM)

- Program evaluation and review technique (PERT)

4. How would you manage a team of production workers?

Here are some of the strategies for managing a team of production workers:

- Set clear goals and expectations to ensure that employees understand what is expected of them.

- Provide regular feedback to employees to help them improve their performance.

- Motivate and engage employees to keep them engaged and productive.

- Create a positive and supportive work environment to encourage teamwork and collaboration.

5. What are the different types of production equipment?

There are many different types of production equipment that can be used in a manufacturing environment. Some common types of production equipment include:

- Assembly machines

- Cutting machines

- Forming machines

- Joining machines

- Inspection machines

- Packaging machines

6. How would you troubleshoot a production problem?

To troubleshoot a production problem, you can follow the following steps:

- Identify the problem

- Gather information

- Analyze the information

- Develop a solution

- Implement the solution

- Evaluate the solution

7. What are the different types of production processes?

There are many different types of production processes that can be used to manufacture products. Some common types of production processes include:

- Batch production

- Continuous production

- Job production

- Project production

8. How would you ensure the quality of a product?

There are many different ways to ensure the quality of a product. Some common methods include:

- Establishing quality standards

- Implementing quality control procedures

- Conducting quality inspections

- Providing training to employees

9. What are the different types of production planning and control techniques?

There are many different types of production planning and control techniques that can be used to improve the efficiency of a production process. Some common types of production planning and control techniques include:

- Material requirements planning (MRP)

- Capacity planning

- Scheduling

- Inventory control

10. How would you improve the safety of a production environment?

There are many different ways to improve the safety of a production environment. Some common methods include:

- Establishing safety rules and procedures

- Providing training to employees

- Conducting safety inspections

- Providing safety equipment

- Encouraging employees to report safety hazards

11. What are the different types of production information systems?

There are many different types of production information systems that can be used to improve the efficiency and effectiveness of a production process. Some common types of production information systems include:

- Manufacturing execution systems (MES)

- Enterprise resource planning (ERP) systems

- Computer-aided design (CAD) systems

- Computer-aided manufacturing (CAM) systems

- Product lifecycle management (PLM) systems

12. How would you manage a production budget?

To manage a production budget, you can follow the following steps:

- Estimate the costs of production

- Identify potential cost savings

- Develop a budget

- Track actual costs

- Control costs

13. What are the different types of production reports?

There are many different types of production reports that can be used to provide information about the performance of a production process. Some common types of production reports include:

- Production schedules

- Production orders

- Inventory reports

- Quality reports

- Cost reports

14. How would you motivate a production team?

There are many different ways to motivate a production team. Some common methods include:

- Providing clear goals and expectations

- Providing feedback and recognition

- Creating a positive work environment

- Offering incentives and rewards

- Providing training and development opportunities

15. What are the different types of production certifications?

There are many different types of production certifications that are available to individuals who want to demonstrate their knowledge and skills in the field of production. Some common types of production certifications include:

- Certified Production Manager (CPM)

- Certified Manufacturing Engineer (CMfgE)

- Certified Production and Inventory Manager (CPIM)

- Certified Six Sigma Green Belt (CSSGB)

- Certified Lean Six Sigma Black Belt (CSSBB)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Leader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Leader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Production Management

Plan, direct, and control all aspects of production, including daily operations, inventory management, and quality assurance.

- Schedule and coordinate production activities, considering resource availability and deadlines.

- Monitor and adjust production schedules as needed to meet demand and ensure efficient operations.

- Implement quality control measures and resolve production issues.

- Maintain production records and documentation for audit and compliance purposes.

2. Team Leadership and Development

Lead, motivate, and develop a workforce of production personnel, ensuring a productive and safe work environment.

- Communicate production goals, policies, and procedures to team members.

- Delegate responsibilities appropriately and hold team members accountable for performance.

- Provide training and support to improve the skills and capabilities of team members.

- Build and maintain a positive and collaborative work environment.

3. Process Optimization and Problem Solving

Identify and implement process improvements to enhance productivity, reduce costs, and improve quality.

- Conduct production audits to identify areas for improvement.

- Develop and execute improvement plans to streamline processes and increase efficiency.

- Troubleshoot and resolve production problems promptly, minimizing downtime.

- Stay abreast of industry best practices and implement innovative solutions.

4. Supply Chain Management

Collaborate with suppliers and external vendors to ensure a reliable and efficient supply chain.

- Establish and manage relationships with suppliers, negotiating contracts and securing material availability.

- Monitor inventory levels and coordinate timely deliveries to meet production requirements.

- Identify and evaluate new suppliers to optimize costs and improve quality.

- Stay informed about supply chain trends and disruptions.

Interview Tips

1. Research the Company and Industry

Demonstrate your knowledge of the company’s products, services, and industry. Show that you understand the company’s goals and how your skills can contribute to their success.

2. Prepare for Behavioral Questions

Review common behavioral interview questions and prepare examples that highlight your leadership, problem-solving, and communication skills. Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

3. Showcase Your Production Expertise

Emphasize your experience in production management, team leadership, and process optimization. Provide quantifiable results and metrics to demonstrate your impact.

4. Highlight Your Problem-Solving Abilities

Share examples of how you identified and resolved production issues. Describe the steps you took to diagnose the problem, develop a solution, and implement it successfully.

5. Ask Insightful Questions

Ask questions about the company’s production processes, performance metrics, and future initiatives. This shows your interest in the role and your ability to contribute to the company’s growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Leader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!