Are you gearing up for an interview for a Production Potter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Production Potter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

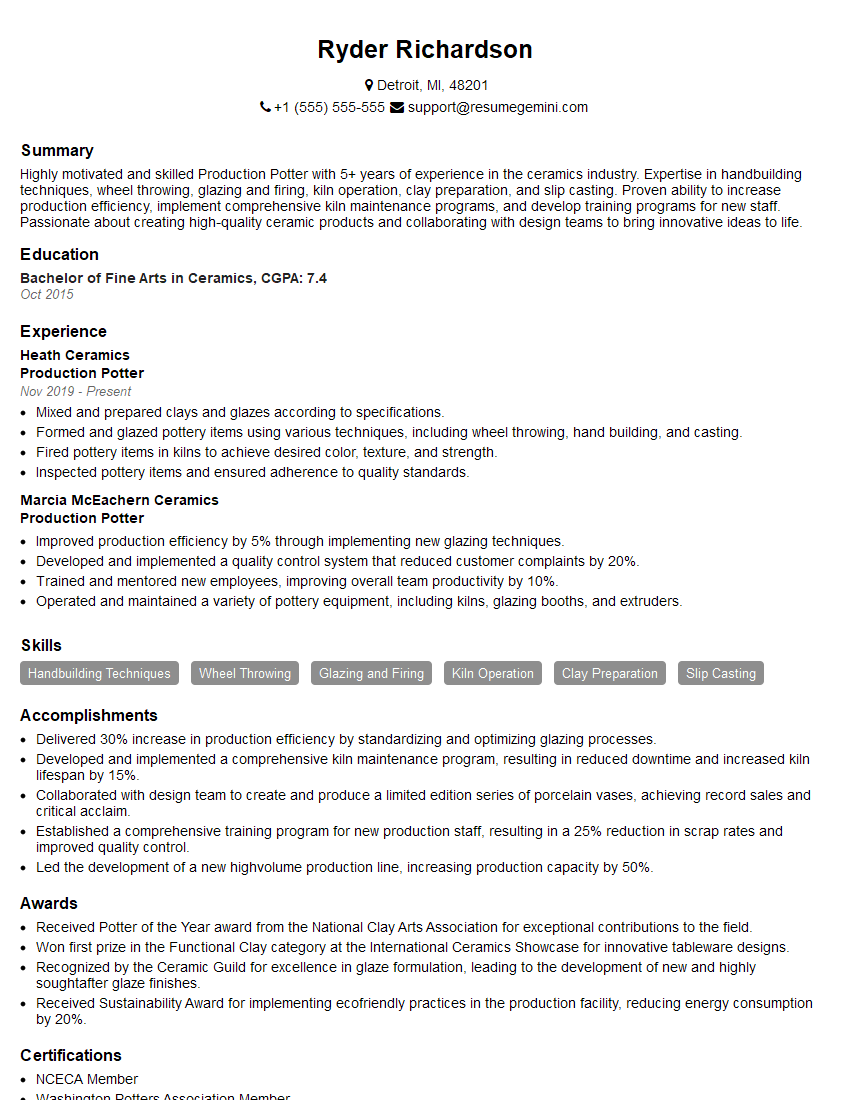

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Potter

1. What are the different types of clays used in pottery and their properties?

- Earthenware clay: Low-firing clay that is porous and opaque, and typically used for making flower pots, tiles, and other decorative items.

- Stoneware clay: Higher-firing clay that is denser and less porous than earthenware, and typically used for making dinnerware, cookware, and other functional items.

- Porcelain clay: Highest-firing clay that is very dense and non-porous, and typically used for making fine china, tiles, and other high-end items.

2. How is clay prepared for use in pottery?

- The clay is first mined from the ground and then crushed into a fine powder.

- The powder is then mixed with water to form a slurry called slip.

- The slip is then filtered to remove any impurities, and then poured into molds or shaped by hand.

- Once the clay has dried, it is fired in a kiln to harden it.

3. What are the different techniques used to shape clay?

- Throwing: Using a potter’s wheel to shape clay by spinning it and using your hands to form it.

- Handbuilding: Shaping clay by hand using techniques such as pinching, coiling, and slab building.

- Casting: Pouring slip into a mold and allowing it to harden, then removing the mold.

- Pressing: Using a press to shape clay into a desired form.

4. What are the different types of glazes used in pottery and their effects?

- Clear glaze: A transparent glaze that allows the color of the clay to show through.

- Colored glaze: A glaze that contains pigments to add color to the pottery.

- Matte glaze: A glaze that has a dull, non-reflective finish.

- Glossy glaze: A glaze that has a shiny, reflective finish.

5. What are the different types of kilns used in pottery and their advantages and disadvantages?

- Electric kiln: Uses electricity to heat the kiln, and is typically used for firing small to medium-sized pieces.

- Gas kiln: Uses gas to heat the kiln, and is typically used for firing large pieces or for achieving higher temperatures.

- Wood-fired kiln: Uses wood to heat the kiln, and is typically used for creating unique and artistic effects.

6. What are the different safety precautions that must be taken when working with pottery?

- Wear a dust mask when working with dry clay to avoid inhaling dust.

- Wear gloves when handling wet clay to avoid skin irritation.

- Avoid touching your face or eyes when working with clay, as it can contain bacteria.

- Never eat or drink in the pottery studio.

- Be aware of the location of the fire extinguisher and know how to use it.

7. What are the different quality control checks that must be performed on pottery before it is sold?

- Check the pottery for any cracks, chips, or other defects.

- Check the pottery for the correct size, shape, and color.

- Check the pottery for any lead or other harmful chemicals.

- Test the pottery to ensure that it is food-safe.

8. What are the different trends in pottery design?

- Minimalism: Simple and understated designs with clean lines and neutral colors.

- Handmade: Pottery with a unique and handmade look, often featuring irregularities and imperfections.

- Sustainability: Pottery made from recycled or sustainable materials, with a focus on reducing environmental impact.

- Technology: Use of 3D printing and other technologies to create innovative and complex designs.

9. What are the different career opportunities for a Production Potter?

- Production Potter: Works in a pottery factory or studio to produce pottery on a large scale.

- Studio Potter: Works independently to create and sell their own pottery.

- Ceramic Artist: Creates unique and artistic pottery, often for galleries or exhibitions.

- Teacher: Teaches pottery classes at schools, community centers, or private studios.

10. What are your strengths and weaknesses as a Production Potter?

- Strengths:

- Ability to produce high-quality pottery in a timely manner

- Excellent attention to detail

- Strong understanding of clay and glazing techniques

- Weaknesses:

- Limited experience with large-scale production

- Not familiar with all types of pottery equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Potter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Potter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Potters are responsible for crafting various ceramic and pottery products in a mass production setting. Key job responsibilities include:

1. Material Preparation and Forming

Preparing clay mixtures, glazes, and other materials used in pottery production.

- Ensuring proper consistency and composition of materials for optimal results.

- Operating machines like pug mills and slip agitators to prepare and mix clay.

2. Molding and Shaping

Using pottery wheels, molds, or other techniques to shape clay into desired forms.

- Creating various shapes and designs as per production specifications.

- Ensuring accurate dimensions and uniformity of products.

3. Drying and Firing

Managing the drying and firing processes of pottery to achieve desired strength and durability.

- Controlling temperature and humidity during drying to prevent cracking or warping.

- Operating kilns and firing pottery according to established temperature and firing schedules.

4. Glazing and Decoration

Applying glazes and decorative elements to enhance the aesthetic appeal and functionality of pottery.

- Choosing and applying appropriate glazes based on desired results.

- Using techniques like dipping, spraying, or brushing to apply glazes evenly.

Interview Tips

To ace an interview for a Production Potter position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and production methods.

- Tailor your responses to highlight your understanding of their specific production processes.

2. Showcase Your Technical Skills

Emphasize your proficiency in pottery-making techniques, including molding, shaping, glazing, and firing.

- Provide specific examples of your experience and highlight your attention to detail and precision.

3. Highlight Your Knowledge of Materials

Demonstrate your understanding of different types of clay, glazes, and other materials used in pottery production.

- Explain how you ensure proper material selection and preparation for optimal results.

4. emphasize Your Quality Control Mindset

Showcase your commitment to quality control and your ability to identify and correct any defects or errors in the production process.

- Discuss your experience in implementing quality control measures and your attention to detail.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Potter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!