Feeling lost in a sea of interview questions? Landed that dream interview for Production Superintendent but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Production Superintendent interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

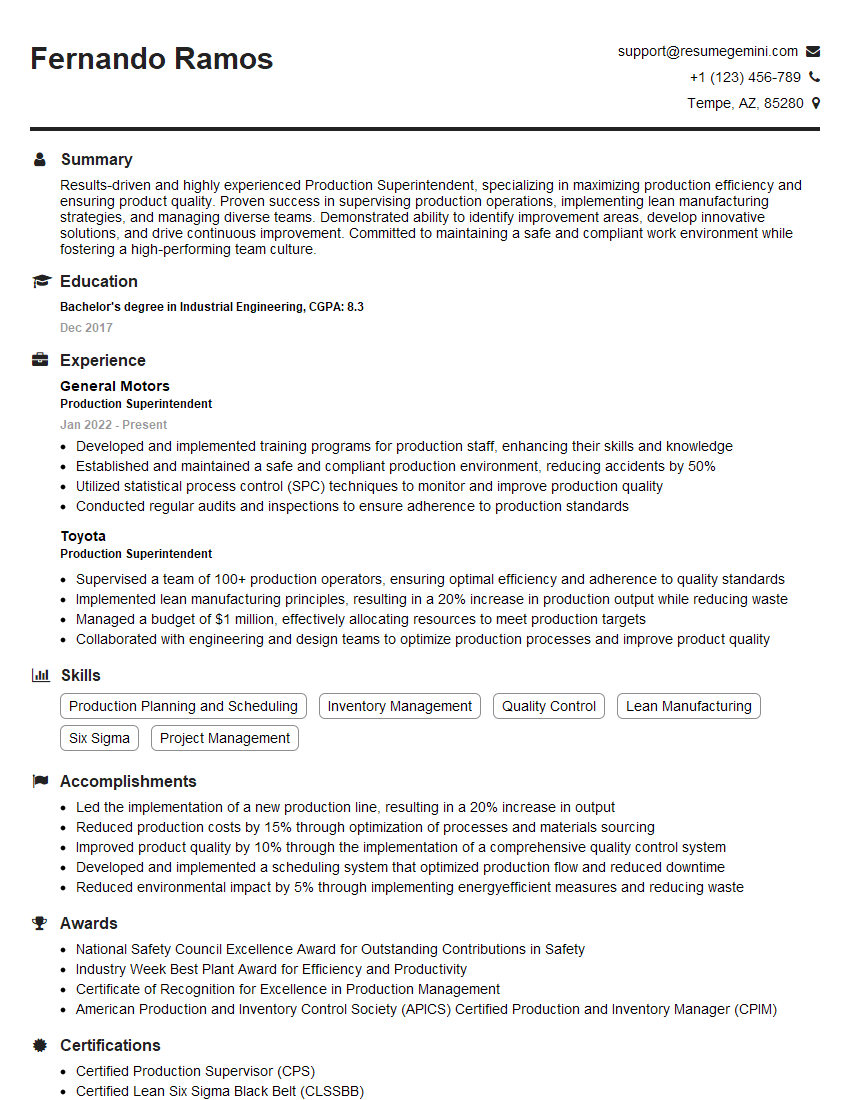

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Superintendent

1. What are the key performance indicators (KPIs) you would use to measure the effectiveness of a production line?

The key performance indicators (KPIs) I would use to measure the effectiveness of a production line are:

- Output: The number of units produced per hour.

- Quality: The percentage of units that meet quality standards.

- Efficiency: The percentage of time that the line is running at its optimal speed.

- Utilization: The percentage of time that the line is actually producing product.

- Cost: The total cost of production, including materials, labor, and overhead.

2. What are the most common problems that you have encountered on a production line and how did you solve them?

Safety Issues

- Inappropriate use of tools

- Lack of safety training

Quality Issues

- Improperly calibrated equipment

- Inadequate inspection procedures

Efficiency Issues

- Poorly designed work processes

- Inadequate training of operators

Cost Issues

- Excessive waste of materials

- Inefficient use of energy

3. What are the different types of production schedules and which one would you use in a given situation?

The different types of production schedules are:

- Make-to-stock: This schedule is used when the demand for a product is relatively stable and predictable. The production schedule is based on the forecast demand for the product.

- Make-to-order: This schedule is used when the demand for a product is highly variable and unpredictable. The production schedule is based on the actual orders that are received from customers.

- Just-in-time (JIT): This schedule is used when the demand for a product is highly volatile and unpredictable. The production schedule is based on the actual demand for the product, and the goal is to produce only what is needed, when it is needed.

4. How do you motivate and lead a team of production workers?

I motivate and lead a team of production workers by:

- Setting clear goals and expectations.

- Providing regular feedback and coaching.

- Recognizing and rewarding success.

- Creating a positive and supportive work environment.

- Empowering my team members to make decisions and take ownership of their work.

5. What are the most important safety considerations for a production line?

The most important safety considerations for a production line are:

- Properly guarding all moving parts.

- Providing adequate lighting and ventilation.

- Training employees on all safety procedures.

- Enforcing safety rules and regulations.

- Conducting regular safety inspections.

6. How do you ensure that products are produced to the highest quality standards?

I ensure that products are produced to the highest quality standards by:

- Establishing clear quality standards.

- Training employees on quality control procedures.

- Conducting regular quality inspections.

- Using statistical process control (SPC) techniques to monitor and improve quality.

- Taking corrective action when quality problems occur.

7. How do you control costs on a production line?

I control costs on a production line by:

- Optimizing the production process to reduce waste.

- Negotiating favorable prices with suppliers.

- Implementing cost-saving initiatives, such as lean manufacturing.

- Monitoring costs and taking corrective action when necessary.

- Investing in preventive maintenance to avoid costly breakdowns.

8. How do you improve the efficiency of a production line?

I improve the efficiency of a production line by:

- Analyzing the production process and identifying bottlenecks.

- Implementing lean manufacturing techniques to reduce waste and improve flow.

- Automating tasks to reduce labor costs.

- Improving the training of employees.

- Investing in new equipment and technology.

9. How do you handle customer complaints?

I handle customer complaints by:

- Listening to the customer’s complaint and understanding their needs.

- Investigating the complaint to determine the cause of the problem.

- Taking corrective action to resolve the complaint.

- Following up with the customer to ensure that they are satisfied with the resolution.

- Using customer complaints as an opportunity to improve the production process.

10. What are your strengths and weaknesses as a Production Superintendent?

My strengths as a Production Superintendent include:

- Strong technical knowledge of production processes.

- Proven ability to lead and motivate a team of production workers.

- Excellent problem-solving skills.

- Strong commitment to quality and safety.

- Ability to work independently and as part of a team.

My weaknesses include:

- Limited experience with some newer production technologies.

- Tendency to be perfectionistic at times.

- Can be impatient with others who do not share my commitment to quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Superintendents oversee the entire production process, ensuring that operations run smoothly and efficiently. Their responsibilities encompass:

1. Production Management

Oversee and coordinate all production activities, including planning, scheduling, and executing production runs.

- Develop and implement production plans to meet customer demand and specifications.

- Schedule and allocate resources, including personnel, equipment, and materials, to optimize production.

2. Quality Control

Maintain high standards of product quality by implementing and enforcing quality control procedures.

- Establish and monitor quality standards throughout the production process.

- Conduct quality inspections and audits to ensure adherence to specifications.

3. Cost Control

Control production costs by optimizing resource utilization and minimizing waste.

- Monitor production costs and identify areas for improvement.

- Negotiate with suppliers to secure favorable pricing and terms.

4. Team Management

Lead and motivate a team of production personnel to achieve production goals.

- Hire, train, and develop production staff.

- Foster a positive and productive work environment.

Interview Tips

To ace a Production Superintendent interview, it’s crucial to prepare thoroughly and demonstrate your understanding of the role’s responsibilities. Here are some essential tips:

1. Research the Company and Position

Gather information about the company’s industry, products, and operations. Study the job description to identify key qualifications and responsibilities.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Practice Answering Common Interview Questions

Prepare answers to expected interview questions, such as:

- “Describe your experience in production management.”

- “How would you improve the efficiency of a production line?”

- “What strategies do you use to ensure product quality?”

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience, such as:

- Production planning and scheduling.

- Quality control and inspection.

- Cost analysis and optimization.

- Team leadership and motivation.

4. Showcase Your Problem-Solving Abilities

Describe situations where you faced challenges in production and how you developed and implemented solutions.

- Use the STAR method (Situation, Task, Action, Result) to present your experiences.

- Quantify your accomplishments whenever possible.

5. Be Enthusiastic and Confident

Demonstrate your passion for production and your confidence in your abilities.

- Maintain a positive and professional demeanor throughout the interview.

- Ask thoughtful questions to show your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Superintendent interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.