Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Production Weigher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Production Weigher so you can tailor your answers to impress potential employers.

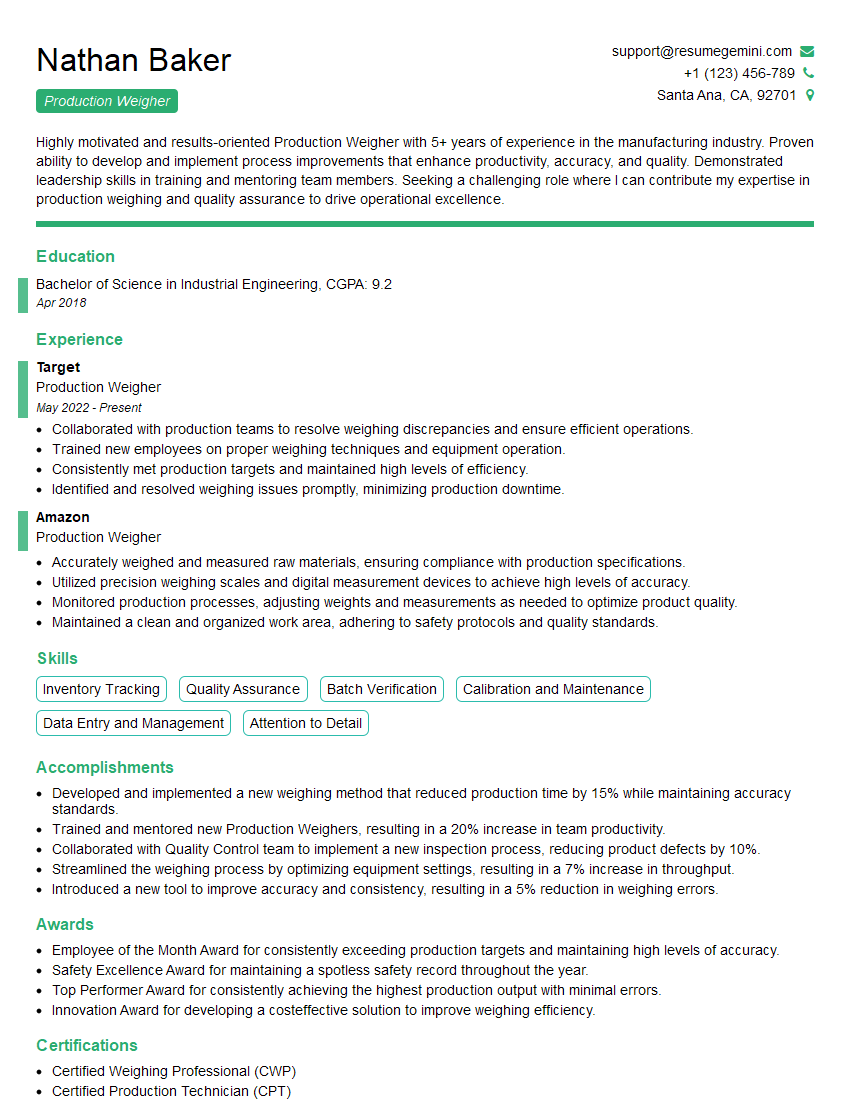

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Weigher

1. How do you ensure the accuracy of your weighing equipment?

To ensure the accuracy of my weighing equipment, I perform the following steps:

- Regular calibration: I calibrate my weighing equipment on a regular basis using certified weights.

- Daily zeroing: I zero the scale daily before using it to ensure that it is accurate.

- Routine maintenance: I perform routine maintenance on my weighing equipment to keep it in good working condition.

- Verification: I verify the accuracy of my weighing equipment by comparing it to other scales or using a reference weight.

2. What is your process for weighing products?

Checking the work order

- I first check the work order to confirm the required weight, quantity, and product details.

Preparing the weighing area

- I prepare the weighing area by ensuring it is clean and free from any debris that could affect the accuracy of the weighing.

Weighing the products

- I place the products on the scale and ensure they are evenly distributed.

- I record the weight and compare it to the specified value on the work order.

Packaging and labeling

- I package the weighed products according to the required specifications.

- I attach the appropriate labels, including the weight, product name, and other relevant information.

3. What do you do if you identify a discrepancy in the weight of a product?

If I identify a discrepancy in the weight of a product, I take the following steps:

- Recheck the weight: I recheck the weight of the product to ensure the initial reading was accurate.

- Inspect the product: I inspect the product for any damage or defects that could have affected its weight.

- Calibrate the scale: I recalibrate the scale to ensure its accuracy.

- Report the issue: I report the discrepancy to my supervisor and provide them with the details.

- Document the incident: I document the incident in the appropriate log or database.

4. How do you maintain a clean and organized weighing area?

To maintain a clean and organized weighing area, I adhere to the following practices:

- Regular cleaning: I clean the weighing area and equipment regularly using appropriate cleaning agents.

- Decluttering: I keep the weighing area free from unnecessary items and materials to prevent clutter.

- Designated storage areas: I designate specific storage areas for equipment, materials, and products to maintain organization.

- Training: I ensure that all individuals using the weighing area are trained on proper cleaning and maintenance procedures.

5. How do you handle the safe disposal of hazardous materials used in the weighing process?

When handling hazardous materials used in the weighing process, I follow strict safety guidelines and procedures:

- Proper storage: I store hazardous materials in designated and secure areas according to regulations.

- Personal protective equipment: I wear appropriate personal protective equipment (PPE) when handling hazardous materials.

- Safe disposal: I dispose of hazardous materials in accordance with established environmental regulations and procedures.

- Training: I am trained on the proper handling and disposal of hazardous materials.

6. How do you ensure that your weighing data is accurate and reliable?

To ensure the accuracy and reliability of my weighing data, I adhere to the following practices:

- Calibration and maintenance: I regularly calibrate and maintain my weighing equipment to meet specified tolerances.

- Proper technique: I use proper weighing techniques and procedures to minimize errors.

- Data recording: I accurately record weighing data and maintain detailed records.

- Review and verification: I review and verify weighing data to identify and correct any discrepancies.

7. How do you prioritize your tasks and manage your time effectively?

To prioritize my tasks and manage my time effectively, I employ the following strategies:

- Prioritization: I prioritize tasks based on their importance and urgency.

- Time management techniques: I use time management techniques such as the Eisenhower Matrix or Pomodoro Technique.

- To-do lists: I create daily to-do lists to stay organized and track my progress.

- Delegation: I delegate tasks to others when appropriate to optimize efficiency.

8. How do you stay up-to-date with the latest weighing industry standards and best practices?

To stay up-to-date with the latest weighing industry standards and best practices, I engage in the following activities:

- Industry publications: I read industry publications, attend conferences, and participate in webinars.

- Professional development: I seek opportunities for professional development, such as training programs and certifications.

- Networking: I network with other professionals in the field to exchange knowledge and best practices.

9. How do you ensure that the products you weigh are packaged and labeled according to customer specifications?

I ensure that the products I weigh are packaged and labeled according to customer specifications by following these steps:

- Reviewing specifications: I carefully review the customer’s specifications for packaging and labeling.

- Preparing packaging materials: I gather the necessary packaging materials and prepare them according to the specifications.

- Packaging products: I package the products carefully and securely, ensuring they are protected from damage and contamination.

- Applying labels: I apply the appropriate labels to the packages, including information such as weight, product name, and any required warnings or instructions.

- Verifying accuracy: I double-check that the packaging and labeling are complete and accurate before dispatching the products.

10. What do you enjoy most about working as a Production Weigher?

I find the following aspects of working as a Production Weigher particularly enjoyable:

- Accuracy and Precision: The role requires meticulous attention to detail and precision, which I enjoy.

- Contribution to Quality Control: I take pride in contributing to the production of high-quality products by ensuring accurate weighing.

- Varied Responsibilities: The job involves a variety of tasks, from weighing products to maintaining equipment and ensuring compliance with regulations.

- Teamwork and Collaboration: I enjoy working as part of a team and interacting with other professionals in the production process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

Production Weighers are responsible for weighing and inspecting products to ensure they meet quality and regulatory standards.

1. Weigh and Inspect Products

A Production Weigher’s primary responsibility is to weigh and inspect products using various weighing equipment such as scales, balances, or weight indicators. They compare actual weight against a predetermined specification to determine if products meet the required weight or weight range.

2. Maintain Equipment and Records

Production Weighers are responsible for maintaining and calibrating weighing equipment to ensure accuracy. They also keep detailed records of all weighing activities, including product type, weight, date, and any discrepancies.

3. Enforce Quality Standards

Production Weighers ensure that products meet safety and quality regulations by inspecting products for defects or contamination. They may also work in conjunction with laboratory personnel to analyze product samples.

4. Product Packaging

In some cases, Production Weighers may also be responsible for packaging weighed products or preparing them for shipment. This may involve placing products in containers, boxes, or bags.

Interview Tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Production Weigher position. This helps you understand the company’s culture and what they are looking for in a candidate.

2. Highlight Your Attention to Detail and Accuracy

Production Weighers must be able to perform their duties with a great degree of precision. Highlight your attention to detail and accuracy on your resume and in the interview.

3. Demonstrate Your Knowledge of Weighing Equipment

If you have previous experience with weighing equipment, make sure to mention this during the interview, providing specific examples of the equipment you have used.

4. Prepare for Industry-Specific Questions

Be prepared to answer questions about your knowledge of industry-specific regulations and standards related to product weighing and inspection.

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions to the interviewer. This shows your interest in the position and the company.

Next Step:

Now that you’re armed with the knowledge of Production Weigher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Production Weigher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini