Are you gearing up for a career in Production Welder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Production Welder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

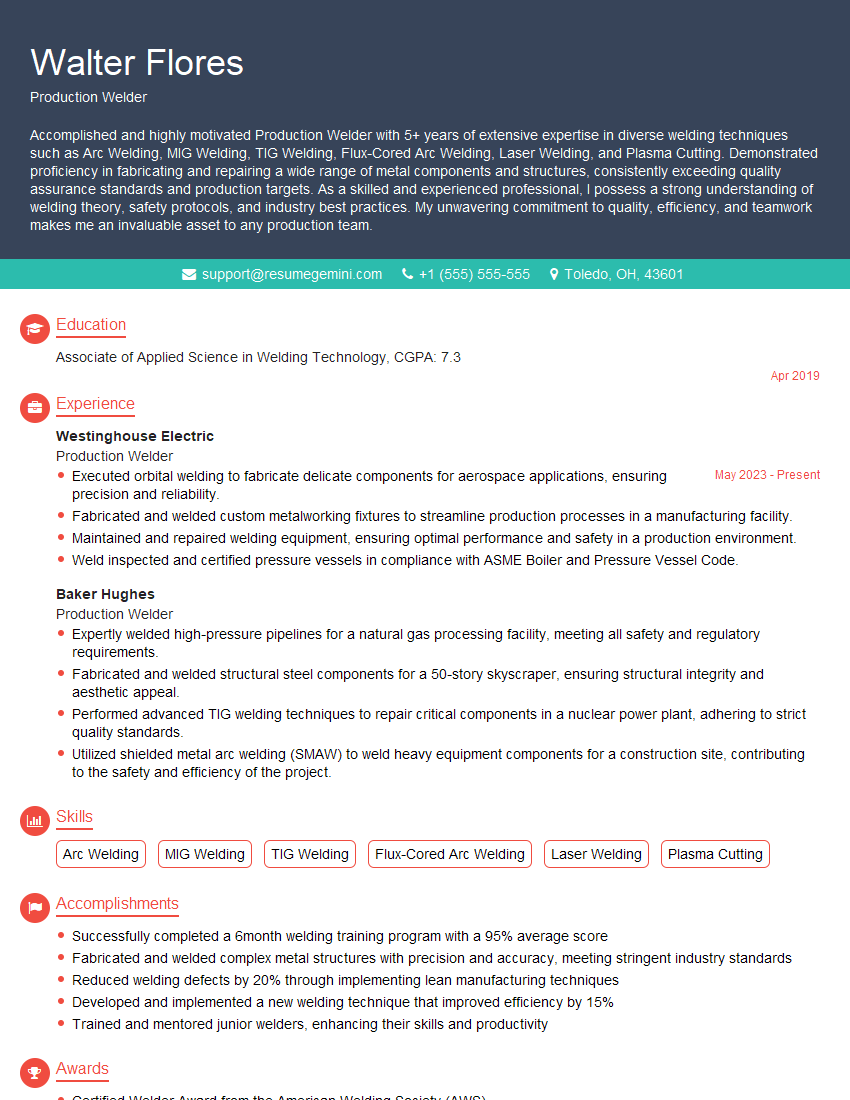

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Welder

1. Which types of welding processes are you familiar with?

I have experience in various welding processes, including:

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Shielded Metal Arc Welding (SMAW)

- Flux-Cored Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

2. What are the different types of welding joints?

Butt joint

- Two pieces of metal abutted together

Edge joint

- Two pieces of metal placed side by side and joined along their edges

Corner joint

- Two pieces of metal joined at a right angle

T-joint

- One piece of metal placed perpendicular to another

Lap joint

- Two pieces of metal overlapped and joined along their edges

3. What are the safety precautions that need to be followed when welding?

I always adhere to strict safety protocols when welding, including:

- Wearing appropriate personal protective equipment (PPE)

- Ensuring proper ventilation and air flow

- Inspecting equipment regularly for any damage

- Following established safety procedures and guidelines

- Storing and handling welding materials safely

4. How do you ensure the quality of your welds?

I maintain high-quality welds through the following practices:

- Thoroughly cleaning and preparing the surfaces to be joined

- Selecting the appropriate welding process and parameters

- Using the correct welding techniques and maintaining proper weld settings

- Visually inspecting welds for any defects or inconsistencies

- Conducting non-destructive testing, such as radiographic or ultrasonic inspection, when required

5. What are the common welding defects and how do you avoid them?

I am familiar with various welding defects and employ preventive measures to minimize their occurrence:

- Porosity: Caused by entrapped gases; avoided by using proper shielding gas and maintaining cleanliness

- Cold lap: Incomplete fusion; avoided by using appropriate welding speed and heat input

- Undercut: Base metal melted away at the edge of the weld; avoided by controlling heat input and torch angle

- Cracks: Occurs due to stress or heat buildup; avoided by preheating, using proper welding techniques, and stress relieving

- Slag inclusions: Trapped slag; avoided by cleaning weld surfaces and using appropriate flux

6. How do you troubleshoot welding problems?

I follow a systematic approach to troubleshoot welding problems:

- Identify the problem and gather information

- Review welding parameters, material specifications, and equipment settings

- Conduct visual inspection and non-destructive testing if necessary

- Consult with experienced welders or engineers

- Adjust parameters, modify techniques, or perform repairs as required

7. What is your experience with welding different types of materials?

I have experience in welding various materials, including:

- Mild steel

- Stainless steel

- Aluminum

- Copper

- Titanium

8. What are the different types of welding equipment that you are familiar with?

I am familiar with a range of welding equipment, such as:

- Welding machines (power sources)

- Welding torches and welding rods

- Shielding gases and regulators

- Welders’ masks and protective gear

- Welding tables and clamps

9. How do you stay up to date with the latest welding techniques and technologies?

I am committed to continuous learning and staying abreast of the latest welding advancements:

- Attend industry workshops and conferences

- Read technical journals and magazines

- Engage in online forums and discussions

- Consult with welding experts and manufacturers

- Pursue further education or certifications

10. Why are you interested in joining our company?

I am eager to join your company because I am impressed by:

- Your commitment to quality and innovation

- The scope and complexity of your production processes

- The opportunity to contribute my skills and experience to your team

- Your reputation for providing ongoing professional development and growth opportunities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Welders play a crucial role in the manufacturing and fabrication industries. They are responsible for joining metal components by applying heat and pressure to fuse them together.

1. Welding Tasks

Production Welders are proficient in various welding techniques, including:

- Arc welding (e.g., MIG, TIG, stick)

- Gas welding (e.g., oxy-acetylene)

- Resistance welding (e.g., spot welding)

2. Reading and Interpreting Technical Drawings

They must be able to precisely follow engineering drawings and specifications to create welds that meet design requirements.

3. Maintaining Equipment

Production Welders are responsible for maintaining their welding equipment, including cleaning and calibrating welding machines.

4. Quality Control

They perform inspections and testing on welded joints to ensure they meet quality standards.

5. Safety Compliance

Production Welders must prioritize safety by following established protocols and wearing appropriate protective gear.

Interview Tips

Preparing thoroughly for a production welder interview can significantly improve your chances of success. Here are some tips to help you ace the interview:

1. Research the Company

- Familiarize yourself with the company’s profile, products/services, and industry standing.

- Learn about their welding processes and technologies.

2. Practice Welding Techniques

- Demonstrate your welding skills by practicing before the interview.

- Focus on precision, consistency, and safety.

3. Prepare for Common Interview Questions

- Review common interview questions related to welding, such as:

- “Describe your experience with different welding techniques”

- “How do you ensure the quality of your welds?”

- “What are the safety precautions you take when welding?”

4. Highlight transferable skills

- Emphasize transferable skills relevant to the role, such as attention to detail, problem-solving abilities, and teamwork.

- Provide examples from your previous work experience to support your claims.

5. Dress professionally

- First impressions matter. Dress appropriately for the interview, considering the industry and company culture.

- Wear comfortable clothing that allows you to move freely.

6. Be enthusiastic and ask questions

- Demonstrate your interest in the position and the company.

- Ask thoughtful questions about the role, the company, and the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!