Are you gearing up for an interview for a Profile Saw Setup Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Profile Saw Setup Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

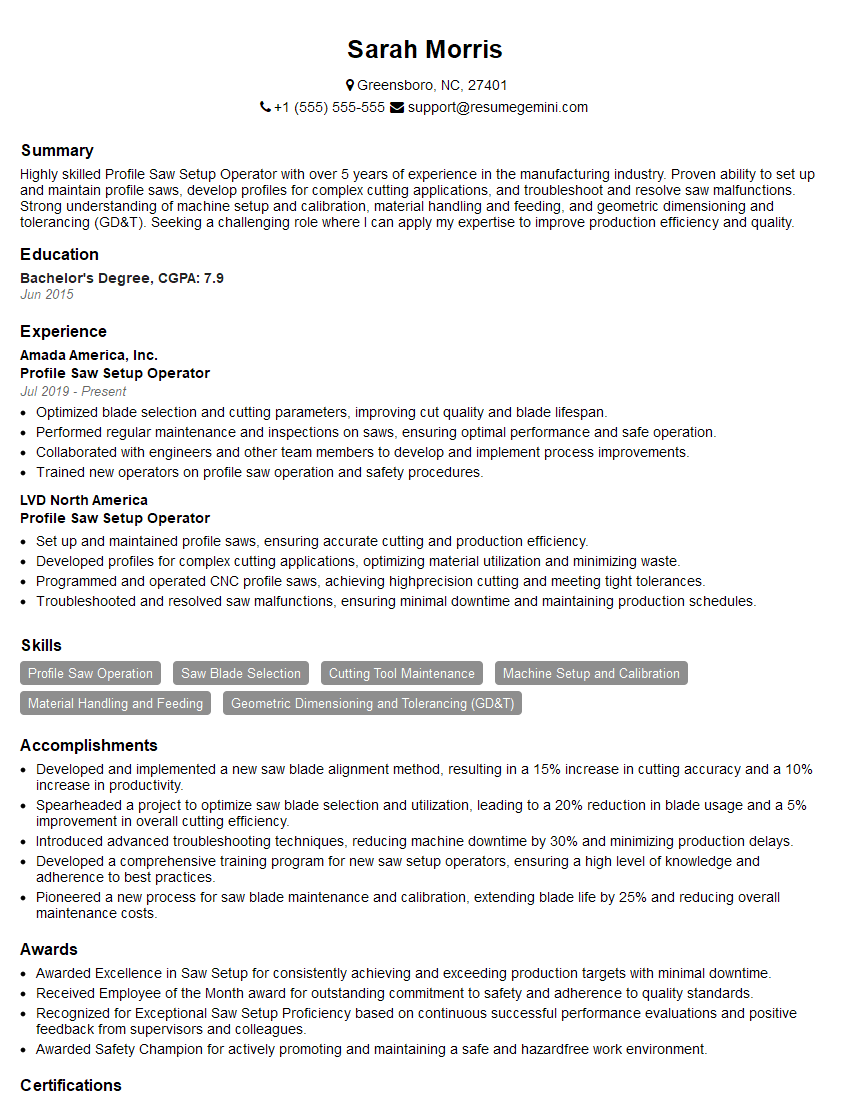

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Profile Saw Setup Operator

1. What are the key responsibilities of a Profile Saw Setup Operator?

As a Profile Saw Setup Operator, my primary responsibilities include:

- Setting up and operating profile saws to cut profiles according to specifications.

- Inspecting raw materials, finished profiles, and cutting tools to ensure quality.

- Monitoring the cutting process, making adjustments as needed to optimize efficiency and minimize waste.

- Maintaining and calibrating equipment, including saws, cutters, and measuring devices.

2. How do you ensure accuracy and precision when setting up profile saws?

Calibrating Equipment

- Regularly calibrate saws, cutters, and measuring devices to industry standards.

- Use precision gauges and measuring tools to ensure accuracy and consistency.

Cutting Tool Selection

- Select the appropriate cutting tool based on the material being cut and the desired profile.

- Adjust the tool’s geometry and cutting parameters to optimize performance.

Setup Process

- Follow established setup procedures and consult technical drawings to ensure proper alignment.

- Use precision shims and spacers to achieve accurate positioning of the cutting tool.

3. What is the importance of coolant in profile sawing?

Coolant plays a crucial role in profile sawing for the following reasons:

- Lubrication: Coolant reduces friction between the cutting tool and workpiece, preventing overheating and tool wear.

- Cooling: It absorbs heat generated during cutting, preventing damage to the workpiece and tool.

- Chip Removal: Coolant flushes away chips and debris, ensuring a clean cutting surface and preventing tool clogging.

- Improved Finish: By cooling the workpiece and tool, coolant reduces thermal distortion and produces a higher-quality finish.

4. Describe the different types of profile saws and their applications.

- Vertical Profile Saws: Used for cutting straight or curved profiles in various materials, including metal, plastic, and wood.

- Horizontal Profile Saws: Suitable for cutting large or heavy workpieces, as they provide better stability and support.

- CNC Profile Saws: Controlled by computer numerical control, these saws offer high precision and accuracy for complex cutting operations.

- Contour Profile Saws: Designed to cut intricate shapes and contours, often used in industries such as aerospace and automotive.

5. What are the safety precautions you observe when operating profile saws?

- Wear appropriate PPE: Safety glasses, gloves, and hearing protection.

- Secure the workpiece: Ensure that workpieces are firmly clamped and secured before cutting.

- Check guards and shields: Verify that saw guards and shields are in place and functioning properly.

- Avoid loose clothing: Remove loose clothing or jewelry that could get caught in moving parts.

- Maintain a clean workspace: Keep the work area clear of debris and ensure proper ventilation.

6. How do you handle and maintain profile saw blades?

To handle and maintain profile saw blades effectively, I follow these steps:

- Proper Storage: Store blades in a cool, dry place away from moisture and impact.

- Regular Inspection: Inspect blades for damage, such as nicks, cracks, or uneven wear, before each use.

- Cleaning: Clean blades regularly using a soft brush or cloth to remove any debris or lubricant.

- Sharpening: Have blades professionally sharpened when they become dull to ensure optimal cutting performance.

- Replacement: Replace blades when they are worn beyond repair or damaged.

7. What are some common problems encountered in profile sawing and how do you resolve them?

- Poor Surface Finish: Can be caused by blunt blades, improper workpiece positioning, or insufficient coolant flow. Resolve by sharpening blades, adjusting setup, or increasing coolant supply.

- Excessive Vibration: May indicate an imbalance in the blade or workpiece. Check for loose components, adjust setup, or replace the blade.

- Blade Chatter: Occurs when the blade resonates at a certain frequency. Adjust the cutting speed, use a different blade, or modify the setup to eliminate resonance.

- Tool Breakage: Can be caused by excessive force, improper tool selection, or hidden defects in the workpiece. Inspect tools carefully, select appropriate tools, and avoid overfeeding.

8. How do you maintain a consistent cutting quality throughout a production run?

To maintain consistent cutting quality throughout a production run, I implement the following measures:

- Standardization: Establish clear and documented cutting parameters, setup procedures, and quality control checks.

- Regular Monitoring: Monitor the cutting process and inspect finished products frequently to identify any deviations from the desired quality.

- Corrective Actions: Promptly address any issues identified during monitoring and implement corrective actions to restore quality.

- Maintenance and Calibration: Regularly maintain and calibrate equipment to ensure optimal performance and accuracy.

9. How do you prioritize competing production demands while maintaining quality standards?

To prioritize competing production demands while maintaining quality standards, I employ the following strategies:

- Communication: Collaborate with production planners and supervisors to understand priorities and timelines.

- Planning: Develop a production schedule that sequences jobs based on urgency and available resources.

- Delegation: Assign tasks to team members based on their skills and capabilities.

- Process Optimization: Continuously improve processes to reduce setup times and cycle times.

- Quality Control: Implement rigorous quality control measures throughout the production process to prevent defects and ensure product quality.

10. How do you stay updated with the latest advancements in profile sawing technology?

To stay updated with the latest advancements in profile sawing technology, I:

- Attend Industry Events: Participate in trade shows and conferences to learn about new technologies and equipment.

- Read Technical Publications: Subscribe to industry magazines and journals to access the latest research and developments.

- Engage with Suppliers: Collaborate with saw manufacturers and suppliers to get insights into emerging trends.

- Online Research: Utilize online resources and technical forums to stay informed about advancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Profile Saw Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Profile Saw Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Profile Saw Setup Operator is responsible for operating and maintaining profile saws, which are used to cut precise shapes into metal. They must be able to read and interpret blueprints, set up and adjust the saw, and operate the machine safely and efficiently. Additional responsibilities may include:

1. Preparing and Setting Up the Saw

This involves ensuring that the saw blade is sharp, the machine is properly calibrated, and all safety guards are in place.

2. Operating the Saw

This involves feeding the metal into the saw, guiding it through the cutting process, and monitoring the progress of the cut.

3. Maintaining the Saw

This involves cleaning and lubricating the machine, as well as performing minor repairs and adjustments.

4. Troubleshooting

This involves identifying and resolving any problems that may occur during the cutting process.

5. Safety

This involves following all safety protocols and procedures, including wearing appropriate protective gear and using the saw only for its intended purpose.

Interview Tips

To prepare for an interview for a Profile Saw Setup Operator position, you should:

1. Research the Company and the Position

This will help you understand the company’s culture and the specific requirements of the position.

2. Practice Answering Common Interview Questions

This will help you feel more confident and prepared during the interview. Some common interview questions for this position include:

- Tell me about your experience operating profile saws.

- How do you ensure that the saw is properly calibrated and maintained?

- What safety protocols do you follow when operating the saw?

- How do you troubleshoot problems that may occur during the cutting process?

- What is your availability?

3. Highlight Your Skills and Experience

Be sure to highlight your skills and experience that are relevant to the position. For example, if you have experience operating a specific type of profile saw, be sure to mention that in your interview.

4. Prepare Questions for the Interviewer

This shows that you are interested in the position and the company. Some good questions to ask include:

- What is the company culture like?

- What are the expectations for this position?

- What opportunities are there for advancement?

5. Dress Professionally

This shows that you are taking the interview seriously and that you are a professional.

6. Be On Time

Punctuality shows that you are reliable and respectful of the interviewer’s time.

7. Be Yourself

The most important thing is to be yourself and to let your personality shine through. This will help you make a good impression on the interviewer and increase your chances of getting the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Profile Saw Setup Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.