Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Profiler Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

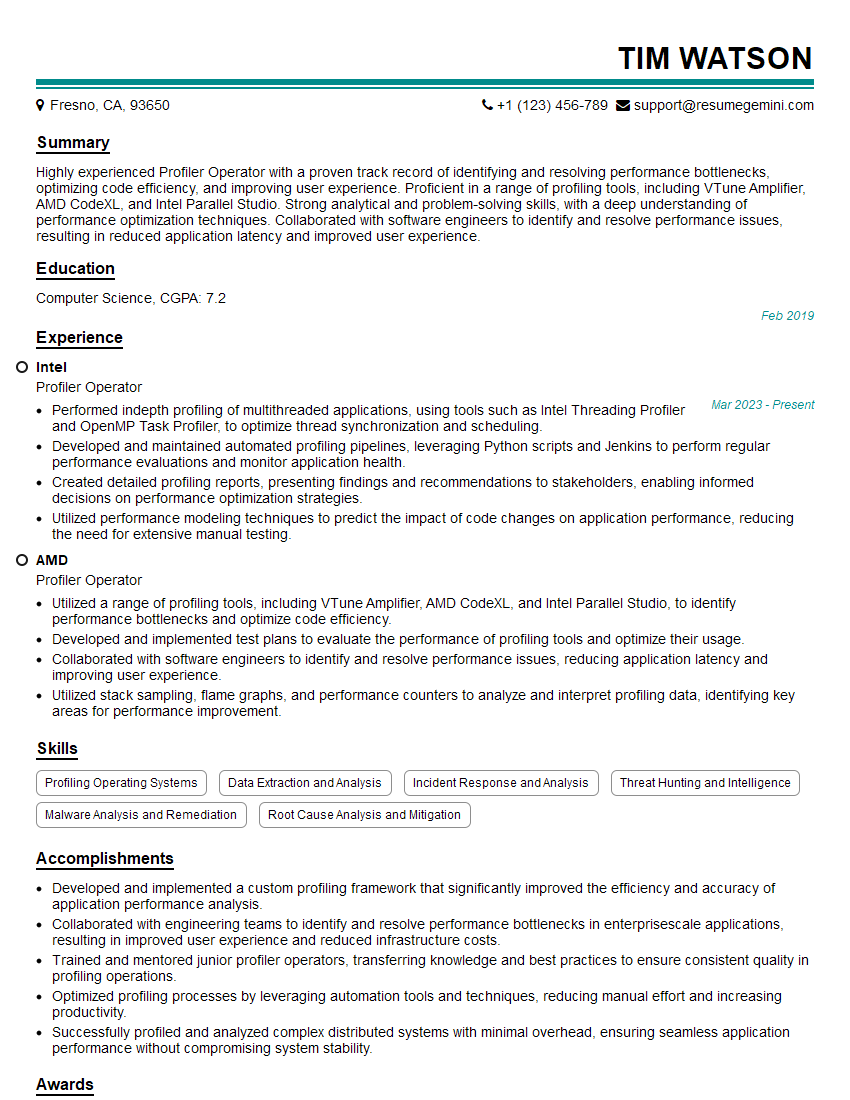

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Profiler Operator

1. What are the key responsibilities of a Profiler Operator?

As a Profiler Operator, my key responsibilities would include:

- Operating and maintaining profile machines to produce high-quality extrusions

- Monitoring and controlling the extrusion process to ensure product quality and efficiency

2. Can you describe the different types of profile extrusion machines and their applications?

Injection Molding Machines

- Produce parts by injecting molten plastic into a mold

- Used for high-precision, complex parts

Extrusion Blow Molding Machines

- Form hollow plastic containers by extruding molten plastic into a mold and then blowing it into shape

- Used for bottles, jugs, and other containers

Thermoforming Machines

- Shape plastic sheets or films by heating and then forming them over a mold

- Used for packaging, automotive parts, and other applications

3. What are the important safety procedures to follow when operating a profile extrusion machine?

The important safety procedures to follow when operating a profile extrusion machine include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Keeping the work area clean and free of tripping hazards

- Following the manufacturer’s instructions for operating the machine

- Never putting hands or other body parts near moving machinery

4. How do you ensure the quality of the extruded profiles?

I ensure the quality of the extruded profiles by:

- Regularly monitoring the extrusion process and making adjustments as needed

- Inspecting the extruded profiles for defects

- Taking corrective action if any defects are found

5. What are the common problems that can occur during the extrusion process and how do you troubleshoot them?

Some common problems that can occur during the extrusion process and how I troubleshoot them include:

- Poor surface finish: This can be caused by a variety of factors, such as incorrect die temperature, improper melt temperature, or contamination of the raw material. I would start by checking these factors and making adjustments as needed.

- Dimensional variations: This can be caused by incorrect die dimensions, improper melt temperature, or fluctuations in the extrusion rate. I would start by checking the die dimensions and making sure that the melt temperature is within the specified range. I would also check the extruder controls to make sure that the extrusion rate is stable.

6. How do you maintain and calibrate the profile extrusion machine?

I maintain and calibrate the profile extrusion machine by:

- Performing regular cleaning and lubrication of the machine

- Checking and adjusting the machine’s settings to ensure optimal performance

- Calibrating the machine using a certified calibration standard

7. What are the key performance indicators (KPIs) that you track to measure your performance as a Profiler Operator?

The key performance indicators (KPIs) that I track to measure my performance as a Profiler Operator include:

- Production output

- Quality of the extruded profiles

- Efficiency of the extrusion process

- Downtime

8. How do you stay up-to-date with the latest developments in the field of profile extrusion?

I stay up-to-date with the latest developments in the field of profile extrusion by:

- Reading industry publications

- Attending industry events

- Networking with other professionals in the field

- Participating in online forums and discussion groups

9. What are your strengths and weaknesses as a Profiler Operator?

My strengths as a Profiler Operator include my:

- Strong technical skills

- Attention to detail

- Problem-solving ability

- Teamwork skills

My weaknesses include my:

- Lack of experience with some of the newer profile extrusion machines

- Occasional difficulty in meeting deadlines under pressure

10. Why are you interested in this Profiler Operator position?

I am interested in this Profiler Operator position because it offers me the opportunity to use my skills and experience to contribute to the success of your company. I am confident that I can make a significant contribution to your team and I am eager to learn more about this opportunity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Profiler Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Profiler Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operating and Maintenance of Profiling Equipment

Operate and maintain a variety of profiling equipment, including contour, CNC, and water jet profilers.

- Set up and calibrate equipment according to specifications.

- Load and unload materials onto and off of equipment.

- Monitor equipment during operation and make adjustments as needed.

- Perform routine maintenance on equipment, including cleaning, lubrication, and troubleshooting.

2. Interpreting Engineering Drawings and Specifications

Interpret engineering drawings and specifications to determine the desired shape and dimensions of the workpiece.

- Identify the different types of lines and symbols used in engineering drawings.

- Understand the different dimensions and tolerances that are specified in engineering drawings.

- Calculate the correct cutting parameters based on the engineering drawings and specifications.

3. Programming and Operating CNC Profilers

Program and operate CNC profilers to produce complex parts and shapes.

- Create CNC programs using a variety of software packages.

- Input the correct cutting parameters into the CNC profiler.

- Monitor the CNC profiler during operation and make adjustments as needed.

4. Quality Control and Inspection

Perform quality control inspections on finished products to ensure they meet the required specifications.

- Inspect the finished product for any defects or errors.

- Measure the finished product to ensure it meets the required dimensions and tolerances.

- Document the results of the quality control inspection.

Interview Tips

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and news articles to learn about the company’s competitors and the latest trends in the industry.

- Identify the key skills and experience that the company is looking for in a Profiler Operator.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”

- Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- You can also practice answering questions with a friend or family member.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Profiler Operator.

- Be prepared to discuss your previous jobs, the equipment you have operated, and the types of projects you have worked on.

- Highlight your skills and experience that are relevant to the position you are applying for.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company.

- This shows that you are interested in the position and that you are taking the interview seriously.

- It also gives you an opportunity to learn more about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Profiler Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!