Are you gearing up for an interview for a Profiling Machine Setup Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Profiling Machine Setup Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

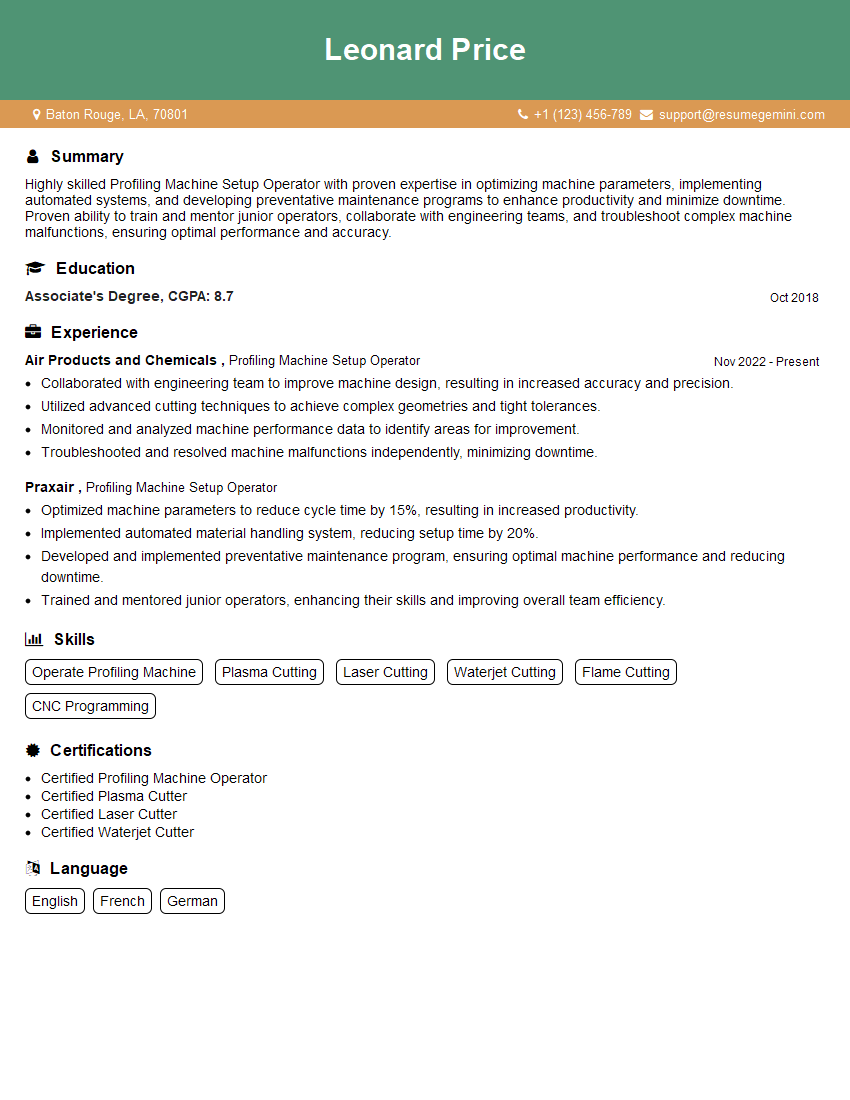

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Profiling Machine Setup Operator

1. What are the key responsibilities of a Profiling Machine Setup Operator?

As a Profiling Machine Setup Operator, I would be responsible for:

- Setting up and calibrating profiling machines to ensure they meet specifications.

- Loading and unloading materials from the machine.

- Monitoring the machine’s operation and making adjustments as needed.

- Troubleshooting and resolving technical issues.

- Maintaining a clean and organized work area.

2. What are the different types of profiling machines and their applications?

There are several types of profiling machines, each with its own applications:

Flame Profiling Machines:

- Used for cutting intricate shapes from metal using an oxy-fuel torch.

- Applications include shipbuilding, automotive, and aerospace industries.

Plasma Profiling Machines:

- Use plasma to cut metal, producing high-quality edges.

- Applications include architectural, automotive, and construction industries.

Waterjet Profiling Machines:

- Utilize a high-pressure water jet to cut a wide range of materials, including metal, glass, and ceramic.

- Applications include aerospace, medical, and jewelry industries.

3. What is the importance of proper setup and calibration of profiling machines?

Proper setup and calibration of profiling machines are crucial because they ensure:

- Accurate and precise cuts

- Optimal machine performance

- Minimized material waste

- Enhanced safety conditions

4. How do you troubleshoot and resolve common technical issues related to profiling machines?

Troubleshooting and resolving technical issues involves:

- Identifying the source of the problem

- Analyzing error codes and messages

- Consulting technical documentation and manuals

- Performing diagnostic tests and inspections

- Implementing appropriate corrective actions

5. What safety precautions should be taken when operating profiling machines?

Essential safety precautions include:

- Wearing appropriate personal protective equipment (PPE)

- Ensuring proper ventilation to minimize fume inhalation

- Following established safety procedures and protocols

- Maintaining a clean and organized work area

- Receiving proper training and authorization to operate the machine

6. How do you ensure that the profiled parts meet the required specifications and quality standards?

To ensure part quality:

- Verify dimensions and tolerances using measuring instruments

- Inspect for defects, such as burrs, scratches, or inconsistencies

- Compare parts to blueprints and specifications

- Make adjustments to the machine or setup as needed

7. How do you handle situations where multiple orders need to be processed simultaneously?

When faced with multiple orders:

- Prioritize orders based on urgency and deadlines

- Plan and schedule machine usage efficiently

- Coordinate with other operators to optimize production

- Communicate effectively with supervisors and customers regarding order status

8. How do you stay updated with the latest advancements in profiling technology?

To stay current:

- Attend industry conferences and workshops

- Read technical publications and articles

- Participate in online forums and discussions

- Network with other professionals in the field

9. How do you maintain a positive and productive work environment?

For a positive work environment:

- Communicate clearly and effectively with colleagues

- Respect diversity and individual differences

- Offer assistance and support to others

- Maintain a positive attitude and enthusiasm

- Contribute to a team-oriented approach

10. Can you provide an example of a situation where you successfully resolved a challenging technical issue on a profiling machine?

During a production run, the plasma cutter on the profiling machine malfunctioned. The error codes indicated a power supply issue. I:

- Isolated the power supply and conducted electrical tests

- Identified a faulty capacitor and replaced it with a spare

- Recalibrated the power supply and tested the cutter

- Resumed production with minimal downtime

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Profiling Machine Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Profiling Machine Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Profiling Machine Setup Operator is accountable for setting up, operating, and maintaining profiling machining equipment. They are also responsible for monitoring the profiling process and ensuring that the products meet the required specifications. Some of the other key job responsibilities include:

1. Programming and operating profiling machines to cut materials to specifications

This involves programming the CNC machine to follow a specific path when cutting materials such as metal, plastic, or wood. The operator must also ensure that the machine is properly set up and that the cutting tools are sharp and in good condition

2. Inspecting and measuring cut parts to verify that they meet customer specifications

The operator will inspect the parts to make sure that they meet the required size, shape, and tolerance. They will also typically use measuring tools to verify the dimensions of the parts

3. Maintaining and troubleshooting profiling equipment to keep it in good working condition

The operator will be responsible for performing routine maintenance on the CNC machine. This may include cleaning and lubricating the machine, replacing worn parts, and adjusting the machine settings. The operator must also be able to identify and fix any problems that arise with the machine

4. Monitoring the profiling process and making adjustments as needed to ensure that parts are being cut to the correct specifications

The operator will monitor the profiling process to ensure that the machine is cutting the material correctly. They will make adjustments to the machine as needed to ensure that parts are being cut to the required specifications

5. Working with other team members to ensure that the profiling process is running smoothly

The operator will work with other members of the production team to ensure that the profiling process is running smoothly. This may include setting up the job, loading and unloading the machine, and cleaning up the work area

Interview Tips

In order to ace the interview, it is important to prepare in advance. Here are a few tips to help you do well:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position. This will help you to understand the company’s culture and what they are looking for in a candidate.

2. Practice answering common interview questions

There are a few common interview questions that you can expect to be asked. It is a good idea to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Dress professionally and arrive on time

It is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you respect the company. You should also arrive on time for your interview. This shows that you are respectful of the interviewer’s time.

4. Be enthusiastic and positive

When you are interviewing for a job, it is important to be enthusiastic and positive. This shows the interviewer that you are excited about the opportunity and that you believe in yourself. It is also important to be positive about your skills and experiences. This will help the interviewer to see that you are confident in your abilities.

5. Follow up after the interview

After the interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you appreciate their time. You can send a thank-you note or an email to the interviewer. In your message, you can reiterate your interest in the position and thank the interviewer for their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Profiling Machine Setup Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Profiling Machine Setup Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.