Are you gearing up for an interview for a Programmable Logic Controller Programmer (PLC Programmer) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Programmable Logic Controller Programmer (PLC Programmer) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

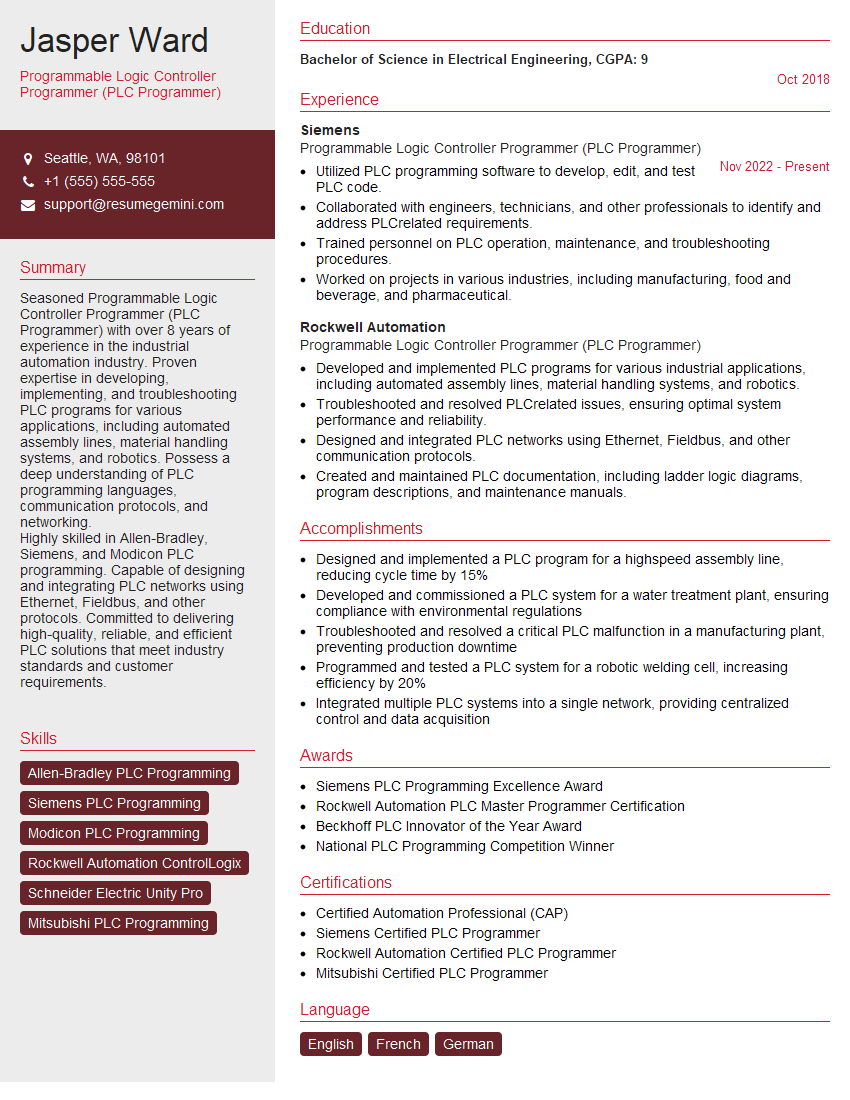

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Programmable Logic Controller Programmer (PLC Programmer)

1. Explain the Ladder Logic Programming and its use?

Ladder logic programming is a graphical programming language used to program PLCs. It is based on the relay ladder logic used in electrical control systems. Ladder logic programs are written using a series of contacts and coils, which are connected together to form a ladder diagram. The contacts represent the inputs to the PLC, and the coils represent the outputs. When an input is turned on, it causes the corresponding contact to close, which in turn causes the corresponding coil to turn on. This allows the PLC to control the outputs based on the inputs.

2. Elaborate on Function Block Diagram (FBD) and its advantages?

Benefits of FBD

- Increased code readability and maintainability

- Improved code reusability

- Reduced development time

- Enhanced debugging capabilities

FBD Description

FBD is a graphical programming language used to program PLCs. It is based on the function block diagram notation used in electrical engineering. FBD programs are written using a series of function blocks, which are connected together to form a diagram. The function blocks represent the functions that the PLC will perform, such as mathematical operations, logical operations, and data manipulation. FBD is a powerful programming language that can be used to create complex control programs.

3. Discuss the role of HMI in PLC systems and its importance?

HMI (Human Machine Interface) is a user interface that allows operators to interact with PLCs. It provides a graphical representation of the PLC program, making it easy for operators to monitor and control the system. HMIs can also be used to input data into the PLC, such as setpoints and parameters. The importance of HMI in PLC systems cannot be overstated. It provides a user-friendly interface that allows operators to easily interact with the system, making it more efficient and productive.

4. How do you approach troubleshooting a PLC program?

Troubleshooting a PLC program involves a systematic approach to identify and resolve errors. Here are the steps involved:

- Check the PLC hardware for any loose connections or faulty components.

- Verify the PLC program for any syntax errors or logical errors.

- Use the PLC’s diagnostic tools to identify any errors or faults in the program.

- Make necessary changes to the PLC program to resolve the errors.

- Test the PLC program to ensure that it is functioning correctly.

5. Explain the concept of PID control and its implementation in PLC programming?

PID Control Concept

PID control (Proportional-Integral-Derivative control) is a widely used control algorithm in industrial automation. It calculates an error value as the difference between a desired setpoint and the measured process variable. This error value is then used to adjust the control output in order to minimize the error.

PID Control Implementation

PID control can be implemented in PLC programming using a variety of methods. One common method is to use a PID function block provided by the PLC manufacturer. This function block typically takes the setpoint, process variable, and error as inputs, and calculates the control output.

6. Elaborate on the different types of PLC communication protocols and their applications?

- Modbus: A widely used protocol for industrial automation, Modbus allows for communication between PLCs, HMIs, and other devices over a variety of physical layers, including RS-232, RS-485, and Ethernet.

- EtherNet/IP: An industrial Ethernet protocol developed by Rockwell Automation, EtherNet/IP is used for high-speed communication between PLCs, HMIs, and other devices on an Ethernet network.

- CANbus: A serial communication protocol designed for automotive applications, CANbus is also used in industrial automation for communication between PLCs, sensors, and other devices in a distributed control system.

- DeviceNet: A communication protocol developed by Rockwell Automation, DeviceNet is used for low-cost communication between PLCs, sensors, and other devices in a distributed control system.

7. Describe the different types of PLC memory and their uses?

- Program Memory: Stores the PLC program code and data.

- Data Memory: Stores data that is used by the PLC program, such as input and output values, timers, and counters.

- Bit Memory: Stores individual bits that can be used for a variety of purposes, such as flags, status indicators, and control signals.

- Timer Memory: Stores the values of timers that are used by the PLC program.

- Counter Memory: Stores the values of counters that are used by the PLC program.

8. Explain the difference between a PLC and a DCS?

- PLC (Programmable Logic Controller): A PLC is a solid-state electronic device that is used to control industrial processes. It is typically used in small to medium-sized applications, such as conveyor systems, packaging machines, and robotics.

- DCS (Distributed Control System): A DCS is a computer-based control system that is used to control large and complex industrial processes. It is typically used in large-scale applications, such as power plants, refineries, and chemical plants.

9. Discuss the importance of documentation in PLC programming?

Proper documentation is essential for PLC programming. It helps to ensure that the program is clear, concise, and maintainable. Good documentation should include:

- A description of the program

- A list of the variables used in the program

- A description of the logic used in the program

- A troubleshooting guide

10. How do you stay up-to-date with the latest trends and technologies in PLC programming?

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Participating in online forums and discussion groups

- Taking online courses and certification programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Programmable Logic Controller Programmer (PLC Programmer).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Programmable Logic Controller Programmer (PLC Programmer)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Programmable Logic Controller Programmer, often abbreviated as PLC Programmer, plays a vital role in the automation industry, with key responsibilities that include:

1. PLC Programming and Design

Designing and developing PLC programs to automate industrial processes and control machinery.

2. PLC Installation and Configuration

Installing and configuring PLCs, ensuring proper integration with other components and systems.

- Point 1

- Point 2

3. Troubleshooting and Maintenance

Troubleshooting and resolving PLC-related issues, maintaining and updating PLC programs for optimal performance.

4. Documentation and Testing

Documenting PLC programs, creating test plans, and performing rigorous testing to ensure accuracy and reliability.

- Point 1

- Point 2

5. Collaboration with Cross-Functional Teams

Working closely with engineers, technicians, and other stakeholders to gather requirements and ensure the alignment of PLC programs with overall project goals.

- Point 1

- Point 2

Interview Tips

To ace your PLC Programmer interview, consider these tips:

1. Brush Up on PLC Programming Fundamentals

Familiarize yourself with key PLC programming concepts, including ladder logic, function blocks, and structured text.

2. Practice Problem-Solving

Practice solving PLC programming challenges to demonstrate your ability to analyze and resolve complex issues.

3. Showcase Your Experience

Highlight your hands-on experience with specific PLC brands and platforms, providing concrete examples of your contributions.

4. Seek Out Industry Certifications

Consider obtaining industry-recognized PLC certifications, such as those from Siemens or Rockwell Automation, to validate your skills.

5. Prepare for Technical Questions

Be prepared to discuss technical concepts, algorithms, and programming techniques related to PLC programming.

6. Research the Company and Position

Thoroughly research the company and the specific PLC Programmer role to tailor your responses and demonstrate your interest.

7. Ask Thoughtful Questions

Prepare insightful questions about the company, team, and project to show your engagement and enthusiasm.

Next Step:

Now that you’re armed with the knowledge of Programmable Logic Controller Programmer (PLC Programmer) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Programmable Logic Controller Programmer (PLC Programmer) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini