Are you gearing up for an interview for a Programmable Logic Controller Technician (PLC Technician) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Programmable Logic Controller Technician (PLC Technician) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

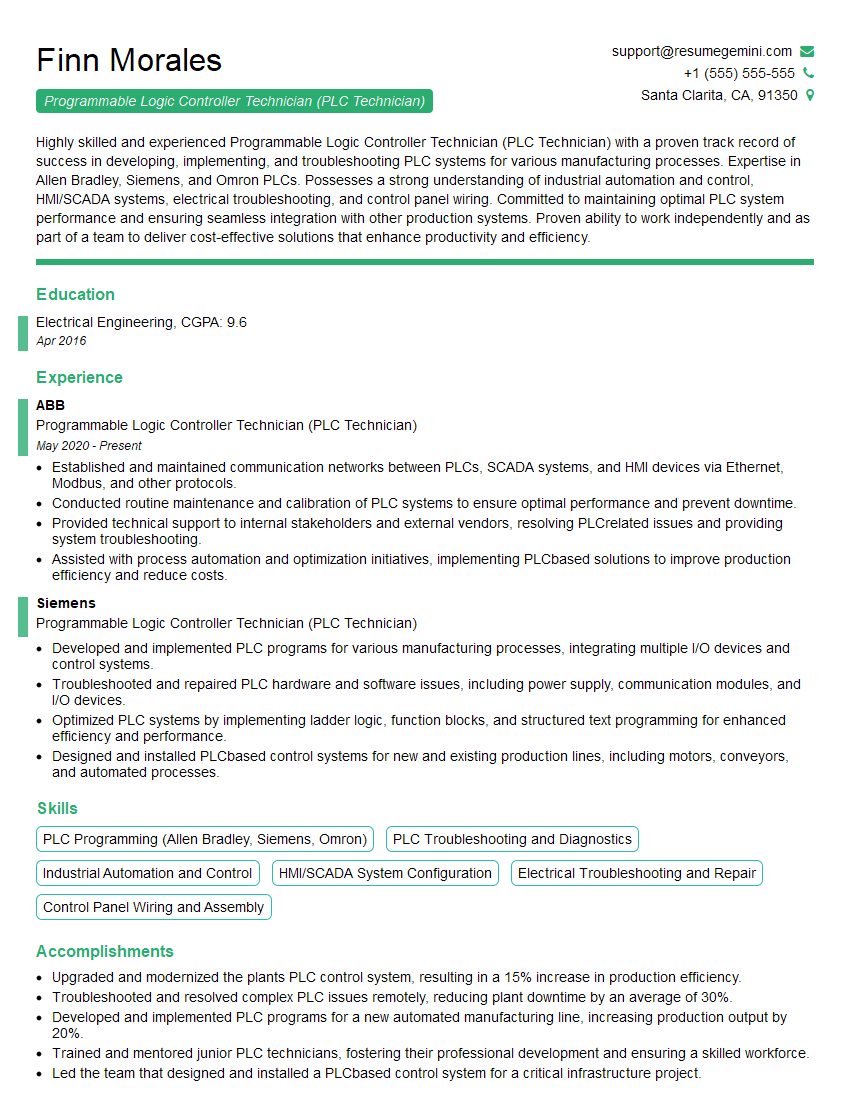

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Programmable Logic Controller Technician (PLC Technician)

1. Explain the difference between a PLC and a DCS?

Answer

- PLC (Programmable Logic Controller) is a solid-state control system designed to automate industrial processes. It consists of a processor unit, input/output modules, a power supply, and a communication interface. PLCs are typically used for small to medium-sized control systems.

- DCS (Distributed Control System) is a computerized control system designed to manage large and complex industrial processes. It consists of a network of controllers, input/output devices, and a central computer system. DCSs are typically used for large-scale control systems.

2. What are the different types of PLC programming languages?

Structured Text

- High-level language based on IEC 61131-3.

- Uses a text editor to create programs.

- Well-suited for complex control applications.

Ladder Logic

- Graphical language that resembles electrical ladder diagrams.

- Easy to understand and use.

- Suitable for simple to medium-sized control applications.

3. What are the different types of PLC input and output modules?

Answer

- Digital Input Modules: Accept binary input signals (on or off) from sensors, switches, or other devices.

- Digital Output Modules: Provide binary output signals (on or off) to control actuators, solenoids, or other devices.

- Analog Input Modules: Convert analog input signals (voltage or current) from sensors or other devices into digital signals.

- Analog Output Modules: Convert digital signals into analog output signals (voltage or current) to control devices such as motors, valves, or transducers.

4. How do you troubleshoot a PLC system?

Answer

- Check the power supply and grounding.

- Check the input and output modules.

- Check the program logic.

- Use a PLC diagnostic tool.

- Contact the PLC manufacturer’s technical support.

5. What are the different types of PLC communication protocols?

Answer

- Modbus: A widely used protocol for communication between PLCs and other devices.

- Ethernet/IP: A protocol developed by Rockwell Automation for use in industrial automation systems.

- DeviceNet: A protocol developed by Allen-Bradley for use in small to medium-sized automation systems.

- PROFIBUS: A protocol developed by Siemens for use in automation systems.

6. What are the different types of PLC software?

Answer

- Ladder Logic Software: Software that allows you to create ladder logic programs.

- Structured Text Software: Software that allows you to create structured text programs.

- Function Block Software: Software that allows you to create function block programs.

- PLC Simulation Software: Software that allows you to simulate a PLC system.

7. What are the advantages of using a PLC?

Answer

- Reliability: PLCs are designed to be reliable and robust.

- Flexibility: PLCs can be easily programmed to perform different tasks.

- Cost-effectiveness: PLCs are relatively inexpensive.

- Ease of use: PLCs are easy to install and use.

8. What are the disadvantages of using a PLC?

Answer

- Complexity: PLCs can be complex to program.

- Troubleshooting: Troubleshooting a PLC system can be challenging.

- Limited I/O: PLCs typically have a limited number of input and output channels.

9. What are the different types of field devices that can be connected to a PLC?

Answer

- Sensors: Sensors detect physical variables such as temperature, pressure, and flow.

- Actuators: Actuators control physical devices such as motors, valves, and solenoids.

- Transducers: Transducers convert one type of signal into another.

10. What are the different types of PLC applications?

Answer

- Manufacturing: PLCs are used to control a wide variety of manufacturing processes.

- Robotics: PLCs are used to control robots.

- Building Automation: PLCs are used to control HVAC systems, lighting systems, and other building systems.

- Transportation: PLCs are used to control traffic signals, rail systems, and other transportation systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Programmable Logic Controller Technician (PLC Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Programmable Logic Controller Technician (PLC Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Programmable Logic Controller Technician (PLC Technician) plays a pivotal role in ensuring the smooth functioning of automated systems in various industrial settings.

1. PLC Programming and Troubleshooting

PLC Technicians are responsible for programming and troubleshooting PLCs, which are the brains of automated systems. They analyze system requirements, develop ladder logic programs, and optimize code for efficiency.

- Developing ladder logic programs to control and sequence automated equipment

- Troubleshooting PLC faults, diagnosing hardware and software issues, and implementing corrective actions

2. Electrical Maintenance and Repair

Beyond PLC programming, PLC Technicians are proficient in electrical maintenance and repair. They ensure the proper operation of electrical components within automated systems.

- Maintaining and repairing electrical panels, wiring, sensors, actuators, and other electrical components

- Performing electrical inspections, ensuring compliance with safety standards and regulations

3. System Integration and Testing

PLC Technicians are involved in system integration, ensuring that PLCs seamlessly communicate with other components in automated systems.

- Integrating PLCs with HMI (Human Machine Interface) systems, SCADA (Supervisory Control and Data Acquisition) systems, and other automation devices

- Conducting system testing, verifying functionality and identifying potential issues before deployment

4. Training and Support

PLC Technicians often provide training to operators and maintenance personnel on the use and maintenance of automated systems.

- Training operators on PLC programming and troubleshooting techniques

- Providing technical support to users, resolving issues and ensuring system uptime

Interview Tips

Preparing thoroughly for a PLC Technician interview is crucial. Here are some essential tips to help you ace the interview:

1. Research the Company and Industry

Research the company’s business, industry trends, and current projects. This demonstrates your interest and preparation.

- Visit the company’s website and LinkedIn page

- Read industry publications and articles

2. Review Key PLC Concepts

Refresh your knowledge of PLC programming, troubleshooting, and electrical maintenance principles. Use online resources or textbooks to review fundamental concepts.

- Ladder logic programming

- PLC hardware and software

- Electrical troubleshooting techniques

3. Practice Troubleshooting Scenarios

Prepare for troubleshooting scenarios by practicing on simulated or real PLC systems. This will help you demonstrate your problem-solving skills.

- Simulate common PLC faults (e.g., sensor failures, logic errors)

- Use diagnostic tools to identify and resolve issues

4. Highlight Your Relevant Experience

Emphasize your previous experience in PLC programming, troubleshooting, and electrical maintenance. Provide specific examples of projects you have worked on.

- Quantify your accomplishments using metrics (e.g., reduced downtime, improved system efficiency)

- Be prepared to discuss challenges you have faced and how you overcame them

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive for the interview on time. Maintain a professional demeanor throughout the interview process.

- Wear business attire

- Be punctual and respectful

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Programmable Logic Controller Technician (PLC Technician) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!