Are you gearing up for a career in Proof Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Proof Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

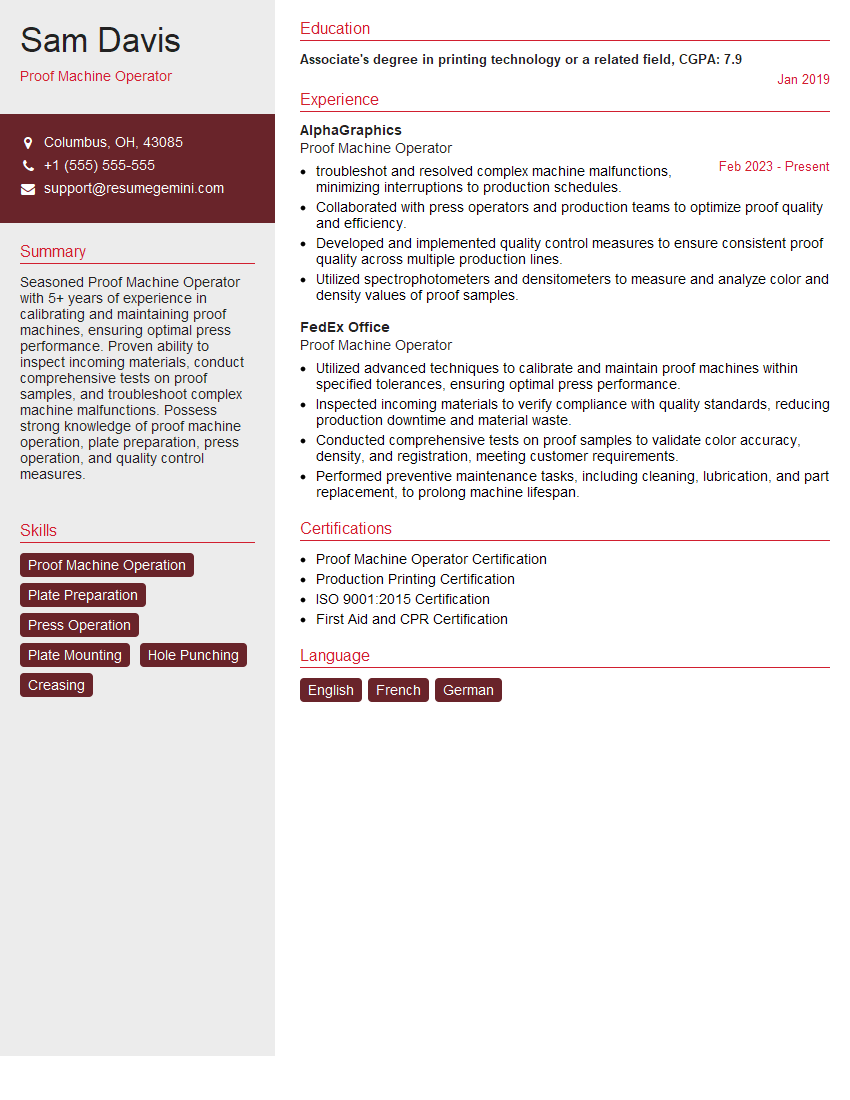

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Proof Machine Operator

1. How do you ensure the accuracy of the proofing process?

To ensure the accuracy of the proofing process, I follow a comprehensive approach that includes:

- Careful plate setup: Meticulously installing printing plates to precise specifications, ensuring proper alignment and pressure.

- Precise ink mixing: Accurately blending inks to match desired colors, using scales or spectrophotometers for precise measurements.

- Substrate preparation: Treating substrates to optimize ink adherence and ensure sharp, high-quality prints.

- Regular machine maintenance: Adhering to scheduled maintenance intervals and inspections, calibrating equipment, and replacing worn parts as needed.

- Proofing verification: Cross-checking proofs against original artwork, using tools such as magnifying glasses or microscopes to identify any deviations.

2. Describe the different types of printing processes and their respective strengths and weaknesses.

Offset printing

- Strengths: Produces high-quality prints with sharp images and accurate colors; suitable for large print runs.

- Weaknesses: Requires complex setup and maintenance; can be expensive for short runs.

Flexography printing

- Strengths: Durable and versatile, suitable for printing on a wide range of materials; cost-effective for long runs.

- Weaknesses: Limited image quality compared to offset printing; not suitable for fine details.

Digital printing

- Strengths: Fast and cost-effective for short runs; allows for variable data printing and personalization.

- Weaknesses: Image quality may not match offset printing; limited substrate options.

3. Explain the role of proof approvals in the printing process.

Proof approvals play a crucial role in the printing process by:

- Ensuring accuracy: Proofs allow clients to review and approve the final product before printing, minimizing the risk of errors.

- Saving costs: Identifying and correcting any issues before printing can prevent costly reprints and delays.

- Maintaining quality standards: Proof approvals ensure that the printed product meets the client’s expectations and conforms to the agreed-upon specifications.

4. How do you handle deviations from the proofed color in the final printed product?

- Identify the cause: Determine if the deviation is due to factors such as paper quality, press conditions, or ink formulation.

- Communicate with the client: Inform the client about the issue and discuss possible solutions, such as adjusting press settings or using alternative materials.

- Implement corrective measures: Make necessary adjustments to the printing process or materials to achieve the desired color match.

- Monitor and document: Keep a record of all corrective actions taken and monitor the results to ensure consistent color accuracy.

5. How do you stay updated with advancements in printing technology?

To stay current with advancements in printing technology, I:

- Attend industry events and conferences: Network with peers and learn about new products and techniques.

- Read trade publications and online resources: Stay informed about the latest industry trends and best practices.

- Seek training and certifications: Enhance my knowledge and skills through workshops and courses.

- Collaborate with vendors and equipment manufacturers: Gain insights into emerging technologies and their potential applications.

6. Describe the safety protocols you follow when operating a proof machine.

When operating a proof machine, I strictly adhere to the following safety protocols:

- Wear appropriate safety gear: Safety glasses, gloves, and earplugs to protect against potential hazards.

- Inspect the machine before use: Check for any loose wires, damaged parts, or leaks.

- Follow proper loading and unloading procedures: Handle materials carefully to avoid injury or equipment damage.

- Never reach into the machine while it’s running: Keep hands and fingers clear of moving parts.

- Report any malfunctions or accidents immediately: Notify supervisors of any issues or potential hazards.

7. How do you troubleshoot common proof machine issues?

- Poor ink flow: Check ink levels, clean nozzles, and inspect ink lines for blockages.

- Proofing defects: Analyze the type of defect (e.g., banding, ghosting) and adjust settings or clean the machine accordingly.

- Machine jams: Identify the source of the jam and carefully remove the paper without damaging the machine.

- Electrical malfunctions: Check power connections, fuses, and circuit breakers; if necessary, contact an electrician.

- Software errors: Restart the machine, check for software updates, and ensure proper driver installation.

8. In a fast-paced printing environment, how do you prioritize and manage your workload effectively?

In a fast-paced printing environment, I prioritize and manage my workload effectively by:

- Planning and organizing: Establishing clear priorities and creating a schedule to ensure timely completion of tasks.

- Multitasking and delegation: Handling multiple tasks simultaneously and delegating responsibilities to colleagues when possible.

- Communicating effectively: Keeping supervisors and colleagues informed about workload and progress, and seeking assistance when needed.

- Utilizing technology: Automating tasks and leveraging software tools to streamline workflow and improve efficiency.

- Maintaining a positive attitude: Staying motivated and focused even under pressure, and approaching challenges with a proactive mindset.

9. Describe a time when you had to handle a challenging proofing project. What steps did you take to ensure its successful completion?

Recently, I encountered a challenging proofing project involving a complex design with intricate colors. To ensure its successful completion, I:

- Consulted with the client: Clarified their expectations and discussed potential challenges.

- Prepared thoroughly: Conducted thorough research on substrate options and ink formulations, and calibrated the proof machine precisely.

- Conducted multiple proofing iterations: Produced proofs using different combinations of settings and materials until the desired results were achieved.

- Communicated regularly: Kept the client informed throughout the process, and sought their feedback after each iteration.

- Ensured accurate color matching: Utilized spectrophotometers and visual comparisons to verify that the proof colors accurately reflected the original artwork.

10. What are your career goals and how do you see this role contributing to them?

My long-term career goal is to become a Production Manager in the printing industry. I believe this role as a Proof Machine Operator will contribute to my goals by:

- Developing foundational skills: Gaining a deep understanding of proofing processes, color management, and printing technologies.

- Building a strong work ethic: Operating a proof machine requires precision, attention to detail, and the ability to work effectively under pressure.

- Understanding production processes: Getting firsthand experience in the prepress phase of printing, and developing insights into the workflow and coordination required for successful print production.

- Networking and collaboration: Interacting with colleagues in other departments and building relationships within the printing industry.

- Demonstrating my commitment: Embracing the responsibilities of this role and delivering high-quality results will showcase my dedication to the printing field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Proof Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Proof Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Proof Machine Operators are responsible for operating and maintaining proof machines, which are used to create proofs of printed materials such as books, magazines, and newspapers. Their primary duties involve ensuring the accuracy and quality of the proofs and adhering to established production schedules.

- Operate proof machines to produce accurate and high-quality proofs.

- Calibrate and maintain proof machines to ensure optimal performance and prevent malfunctions.

- Monitor machine operations and troubleshoot any technical issues that arise.

- Inspect proofs carefully to identify and correct errors in text, layout, or color matching.

- Evaluate proofs to ensure they meet the required quality standards and customer specifications.

- Provide feedback to the production team regarding any necessary adjustments or modifications to the printing process.

- Plan and schedule proof production to meet deadlines and ensure timely delivery to customers.

- Maintain accurate records of proof production, including job details, materials used, and production times.

- Coordinate with the production team to ensure smooth workflow and minimize delays.

- Establish and implement quality control measures to ensure the accuracy and consistency of proofs.

- Inspect proofs for defects and errors, and take corrective actions to prevent their recurrence.

- Maintain a clean and organized work area to promote quality and efficiency.

1. Machine Operation

2. Proof Inspection and Evaluation

3. Production Management

4. Quality Control

Interview Tips

Preparing thoroughly for a Proof Machine Operator interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

- Gather information about the company, its products or services, and the specific requirements of the Proof Machine Operator position.

- This will enable you to tailor your answers to the interviewer’s questions and demonstrate your understanding of the role.

- Emphasize your proficiency in operating and maintaining proof machines, as well as your attention to detail and accuracy.

- Provide specific examples from your previous work experience that showcase your ability to identify and correct errors, maintain quality standards, and meet production deadlines.

- Anticipate questions about the technical aspects of proof machine operation, such as calibration, troubleshooting, and quality control procedures.

- Review the specifications of different proof machines and be prepared to discuss your knowledge of their capabilities and limitations.

- Proof Machine Operators often work as part of a production team and need to communicate effectively with other team members.

- Highlight your ability to collaborate, provide constructive feedback, and contribute to maintaining a positive work environment.

- Asking thoughtful questions at the end of the interview shows your interest in the position and the company.

- Prepare questions about the company’s production processes, quality control measures, and opportunities for professional development.

1. Research the Company and Position

2. Highlight Relevant Skills and Experience

3. Prepare for Technical Questions

4. Demonstrate Your Communication and Teamwork Skills

5. Prepare Questions for the Interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Proof Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!