Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Proof Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

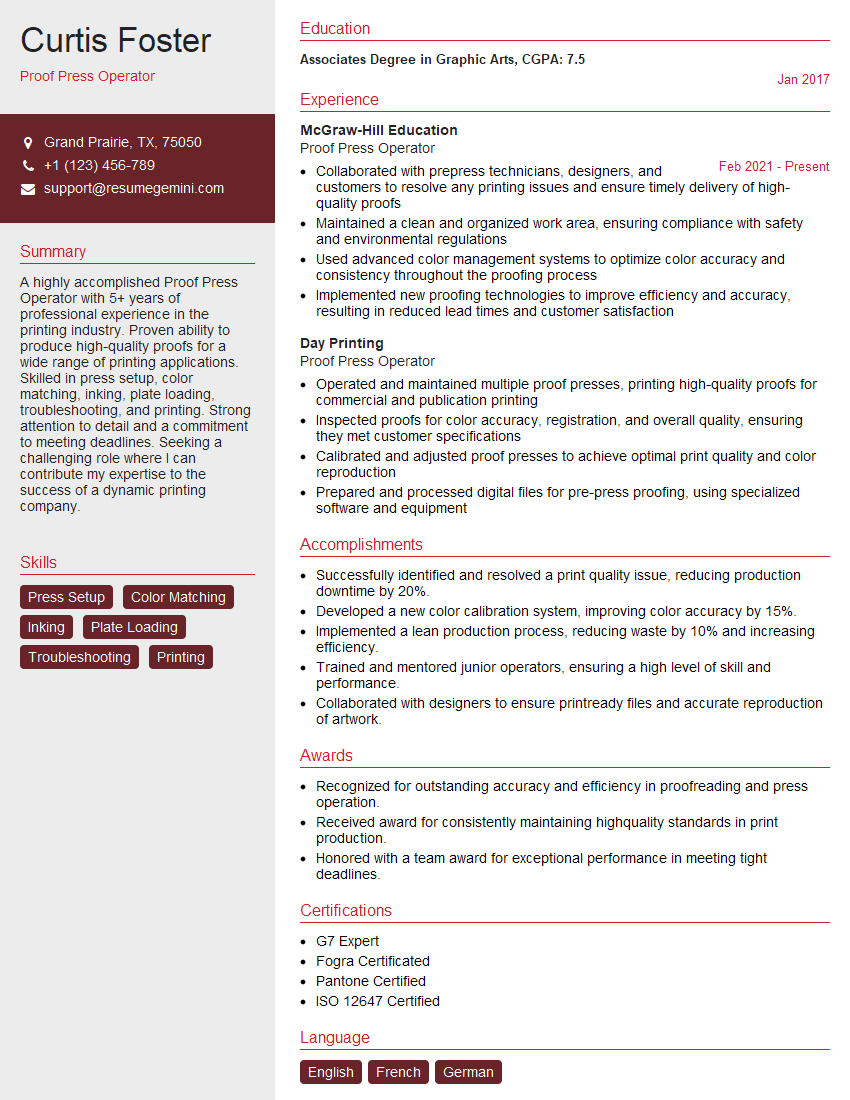

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Proof Press Operator

1. Describe the process of creating and operating a press proof?

The process of creating a press proof involves several steps:

- Prepare the press: Ensure that the press is clean and calibrated, and that the appropriate plates and paper are loaded.

- Make a test print: Run a small test print to check the alignment and quality of the image.

- Adjust the press: Based on the test print, make necessary adjustments to the press settings, such as ink flow, pressure, and registration.

- Run the press proof: Once the press is adjusted, run the desired number of press proofs.

- Inspect the press proof: Carefully inspect the press proofs for any defects or errors, such as misalignment, color accuracy, or ink smudging.

2. What are the different types of press proofs, and what are their respective purposes?

Blue Proofs

- Used to check the overall layout and design of a publication.

- Show the position of text, images, and graphics.

Brown Proofs

- Used to check the color accuracy of a publication.

- Provide a more realistic representation of the final printed product than blue proofs.

Progressive Proofs

- Used to check the progression of color printing.

- Show each color separation individually, as well as the combination of colors.

3. How do you ensure the accuracy and consistency of press proofs?

To ensure the accuracy and consistency of press proofs, I follow several best practices:

- Calibrate the press regularly: Use a densitometer to calibrate the press and ensure consistent ink density and color accuracy.

- Use standardized materials: Use the same paper and ink each time to minimize variations in proof quality.

- Proof under controlled conditions: Proof in a controlled environment with consistent temperature and humidity to prevent external factors from affecting the proof’s accuracy.

- Inspect proofs thoroughly: Carefully inspect each proof for any defects or errors before approving it for final printing.

- Archive proofs: Keep a record of all press proofs for future reference and comparison.

4. What are some common problems that can occur during the press proofing process, and how do you troubleshoot them?

Here are some common problems that can occur during press proofing and how I troubleshoot them:

Misregistration

- Check the alignment of the plates.

- Adjust the press settings to ensure proper registration.

Ink smudging

- Check the ink flow and adjust as necessary.

- Clean the rollers and blankets to remove any excess ink.

Color inaccuracies

- Calibrate the press to ensure accurate color reproduction.

- Check the ink density and adjust as needed.

5. How do you stay updated on the latest trends and technologies in press proofing?

I stay updated on the latest trends and technologies in press proofing through various methods:

- Attend industry events and conferences: Participate in industry events to learn about new products and techniques.

- Read trade publications and online resources: Keep up with industry news and developments through publications and online forums.

- Network with other professionals: Connect with other press proofing professionals to exchange knowledge and best practices.

- Attend training and workshops: Regularly participate in training opportunities to enhance my skills and stay abreast of new technologies.

6. How do you handle tight deadlines and high-pressure situations in the press proofing process?

In situations with tight deadlines and high pressure, I prioritize the following steps:

- Plan and organize: Establish a clear plan and timeline for the proofing process.

- Communicate effectively: Maintain open communication with the team to ensure everyone is aware of the deadlines and expectations.

- Delegate tasks: If possible, delegate tasks to other team members to distribute the workload.

- Stay focused and prioritize: Focus on completing the most important tasks first and prioritize quality over speed.

- Seek support when needed: Don’t hesitate to ask for help from colleagues or supervisors if needed.

7. How do you ensure the confidentiality and security of sensitive printing materials?

To ensure the confidentiality and security of sensitive printing materials, I adhere to the following practices:

- Controlled access: Limit access to printing materials to authorized personnel only.

- Secure storage: Store sensitive materials in a locked and secure location.

- Proper disposal: Shred or destroy sensitive materials after use to prevent unauthorized access.

- Compliance with regulations: Follow all applicable laws and regulations regarding the handling of confidential information.

8. What are your strengths and weaknesses as a Proof Press Operator?

Strengths

- Strong technical skills in press proofing equipment and processes.

- Excellent attention to detail and ability to identify and correct errors.

- Ability to work independently and as part of a team.

Weaknesses

- Limited experience with some specialized press proofing techniques.

- Working under tight deadlines can sometimes lead to stress.

9. How do you measure the quality of a press proof?

I evaluate the quality of a press proof based on several criteria:

- Color accuracy: Compare the proof to the original design to ensure that the colors are reproduced faithfully.

- Registration: Check that all elements of the proof are properly aligned and in register.

- Sharpness: Examine the proof for any blurring or lack of detail.

- Overall appearance: Assess the overall look and feel of the proof to ensure that it meets the desired standards.

10. What is your understanding of the latest industry standards and best practices for press proofing?

I stay abreast of the latest industry standards and best practices for press proofing through ongoing education and professional development. Here are some key areas:

- ISO 12647: Familiar with the international standard for the control of print and digital color.

- G7 calibration: Understand the process of calibrating presses to achieve consistent color reproduction.

- Digital proofing: Knowledgeable about the use of digital proofing systems to create accurate representations of final prints.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Proof Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Proof Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Proof Press Operators are responsible for ensuring that printed materials meet quality standards. They operate proof presses to produce proofs of printed materials, and they inspect the proofs for errors. Proof Press Operators may also make minor adjustments to the printing press to correct errors.

1. Operate proof presses

Proof Press Operators use proof presses to produce proofs of printed materials. Proofs are used to check the quality of the printing, and to make sure that the printed materials meet the customer’s specifications.

2. Inspect proofs for errors

Proof Press Operators inspect proofs for errors. They look for errors in the printing, such as smudges, streaks, or misaligned text. They also check for errors in the content of the printed materials, such as spelling errors or grammatical errors.

3. Make minor adjustments to the printing press

Proof Press Operators may make minor adjustments to the printing press to correct errors. For example, they may adjust the ink flow or the paper feed to improve the quality of the printing.

4. Maintain the printing press

Proof Press Operators are responsible for maintaining the printing press. They clean the press regularly, and they lubricate the moving parts. They also make minor repairs to the press, such as replacing worn parts.

Interview Tips

1. Research the company and the position

- Visit the company’s website to learn about their business, their products or services, and their culture.

- Read online reviews of the company to get a sense of what it’s like to work there.

- Review the job description carefully to understand the specific requirements of the position.

2. Practice your answers to common interview questions

- Some common interview questions include: Tell me about yourself. Why are you interested in this position? What are your strengths and weaknesses? What are your salary expectations? Can you tell me about a time when you had to deal with a difficult customer?

- Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Dress professionally and arrive on time for your interview

- First impressions matter, so make sure you dress professionally for your interview.

- Arrive on time for your interview, or even a few minutes early.

4. Be prepared to ask questions

- Asking questions at the end of the interview shows that you’re interested in the position and the company.

- Some good questions to ask include: What are the biggest challenges facing the company right now? What are the opportunities for advancement within the company? What is the company culture like?

5. Follow up after your interview

- After your interview, send a thank-you note to the interviewer.

- In your thank-you note, reiterate your interest in the position and thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Proof Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.