Are you gearing up for an interview for a Propellant Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Propellant Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

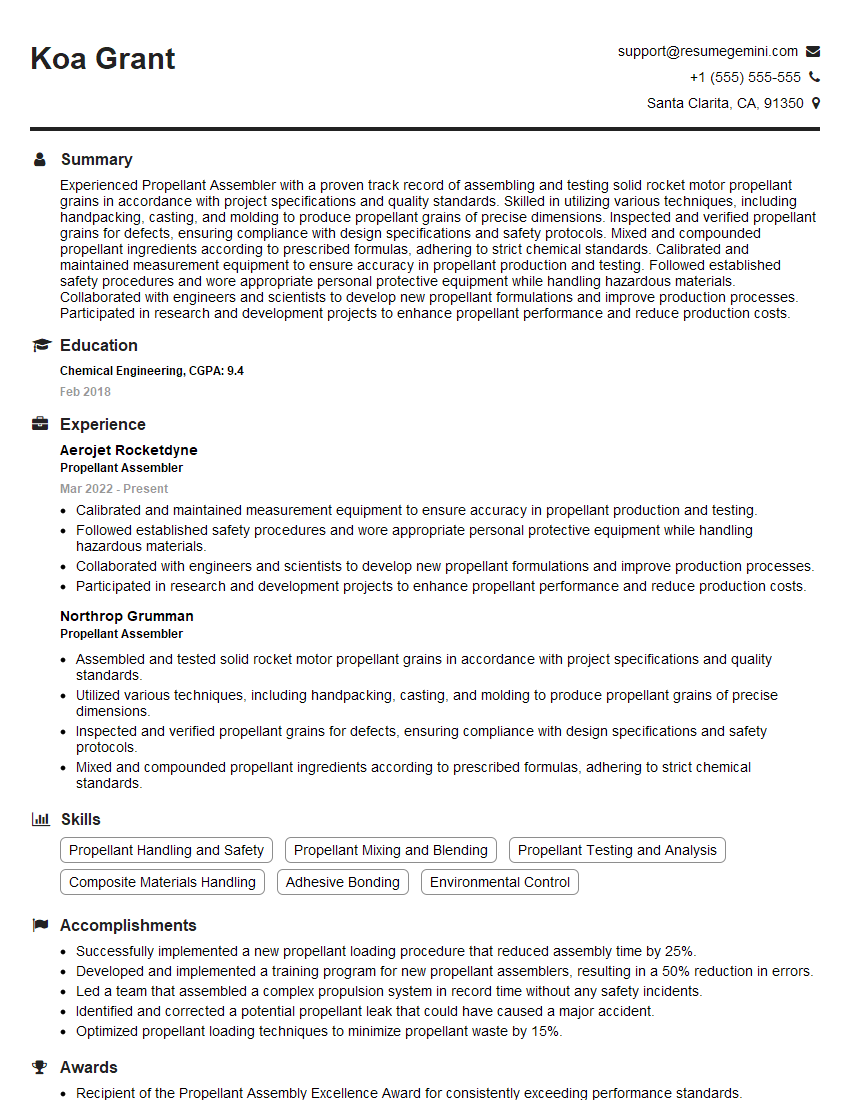

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Propellant Assembler

1. Describe the basic procedures and techniques used for assembling propellants.

The basic procedures and techniques used for assembling propellants include:

- Mixing the propellant components together.

- Curing the propellant mixture.

- Casting the propellant mixture into a mold.

- Testing the propellant mixture to ensure that it meets specifications.

2. What are the different types of propellants that you have worked with?

The different types of propellants that I have worked with include:

- Solid propellants

- Liquid propellants

- Gaseous propellants

I have experience with a variety of different propellants, and I am familiar with the unique characteristics of each type of propellant.

3. What is the difference between a solid propellant and a liquid propellant?

Solid propellants are typically made of a mixture of oxidizer and fuel, while liquid propellants are typically made of a mixture of oxidizer and fuel that is dissolved in a solvent. Solid propellants are typically more stable than liquid propellants, but they are also more difficult to control. Liquid propellants are typically easier to control than solid propellants, but they are also more volatile.

4. What are the safety precautions that you take when working with propellants?

When working with propellants, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Store propellants in a safe and secure location.

- Follow all safety procedures and protocols.

5. What are the quality control procedures that you follow when assembling propellants?

The quality control procedures that I follow when assembling propellants include:

- Inspecting all materials and components before use.

- Following all assembly procedures and protocols.

- Testing the propellant mixture to ensure that it meets specifications.

- Documenting all quality control procedures.

6. What are the different types of equipment that you use when assembling propellants?

The different types of equipment that I use when assembling propellants include:

- Mixers

- Curing ovens

- Casting molds

- Testing equipment

I am familiar with the operation and maintenance of all of the equipment that is used in the propellant assembly process.

7. What are the challenges that you have faced in your previous role as a Propellant Assembler?

One of the challenges that I have faced in my previous role as a Propellant Assembler is the need to work with a variety of different propellants. Each type of propellant has its own unique characteristics, and it is important to be familiar with the safety precautions and handling procedures for each type of propellant.

8. What are your strengths as a Propellant Assembler?

My strengths as a Propellant Assembler include:

- My attention to detail

- My ability to follow instructions

- My experience with a variety of different propellants

- My commitment to safety

I am confident that I have the skills and experience necessary to be a successful Propellant Assembler.

9. What are your career goals?

My career goal is to become a Propellant Production Supervisor. I am confident that I have the skills and experience necessary to be successful in this role, and I am eager to take on the challenges and responsibilities of this position.

10. Do you have any questions for me?

I do have a few questions for you:

- What is the company culture like?

- What are the opportunities for advancement within the company?

- What are the company’s safety policies and procedures?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Propellant Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Propellant Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Propellant Assemblers are an essential part of the manufacturing process for rockets and missiles. They are responsible for assembling and testing the fuel and oxidizer that propel these vehicles. Their work is critical to ensuring the safety and success of these missions.

1. Assembly of Propellant Components

Propellant Assemblers assemble and prepare various components of the propellant system, such as fuel tanks, oxidizer tanks, and feed lines. They must ensure that all components are properly fitted and sealed to prevent leaks or failures during operation.

2. Inspection and Testing

Before propellant components can be installed, they must be thoroughly inspected and tested to ensure they meet safety and performance standards. Propellant Assemblers conduct visual inspections, pressure tests, and other evaluations to verify the integrity of the components.

3. Leak Detection and Repair

Any leaks in the propellant system can be catastrophic. Propellant Assemblers are responsible for detecting and repairing any leaks that may occur during assembly or testing. This involves using specialized equipment and techniques to identify and seal leaks effectively.

4. Documentation and Record Keeping

Propellant Assemblers maintain detailed records of assembly procedures, inspection results, and leak tests. This documentation is crucial for ensuring the traceability and accountability of all components and processes involved in propellant assembly.

Interview Tips

Preparing for an interview for a Propellant Assembler position requires specific knowledge and strategies. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the specific company you’re applying to and the role of Propellant Assembler within their organization. This shows that you’re genuinely interested in the position and have taken the time to understand their business.

2. Highlight Relevant Experience and Skills

Emphasize your experience in assembling and testing mechanical components, particularly in the aerospace or defense industry. Highlight your knowledge of propellant handling procedures and safety regulations.

3. Demonstrate Technical Expertise

Be prepared to discuss your understanding of propellant systems, including fuel types, oxidizers, and combustion processes. You may also be asked about leak detection techniques and repair methods.

4. Showcase Attention to Detail

Propellant Assembly requires meticulous attention to detail. In your interview, provide examples of your ability to follow instructions carefully, conduct thorough inspections, and maintain precise records.

5. Emphasize Safety and Quality

Safety is paramount in propellant handling. Describe your commitment to adhering to all safety protocols and your understanding of quality assurance procedures.

6. Prepare for Situational Questions

You may encounter situational questions during your interview. Consider scenarios involving leak detection, assembly challenges, or quality control issues and prepare your responses to demonstrate your problem-solving abilities.

7. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive on time for your interview. This shows respect for the interviewer and the organization.

8. Ask Meaningful Questions

At the end of your interview, it’s appropriate to ask the interviewer questions about the company, the position, or the industry. This demonstrates your engagement and interest.

Next Step:

Now that you’re armed with the knowledge of Propellant Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Propellant Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini