Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Propellant Charge Zone Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

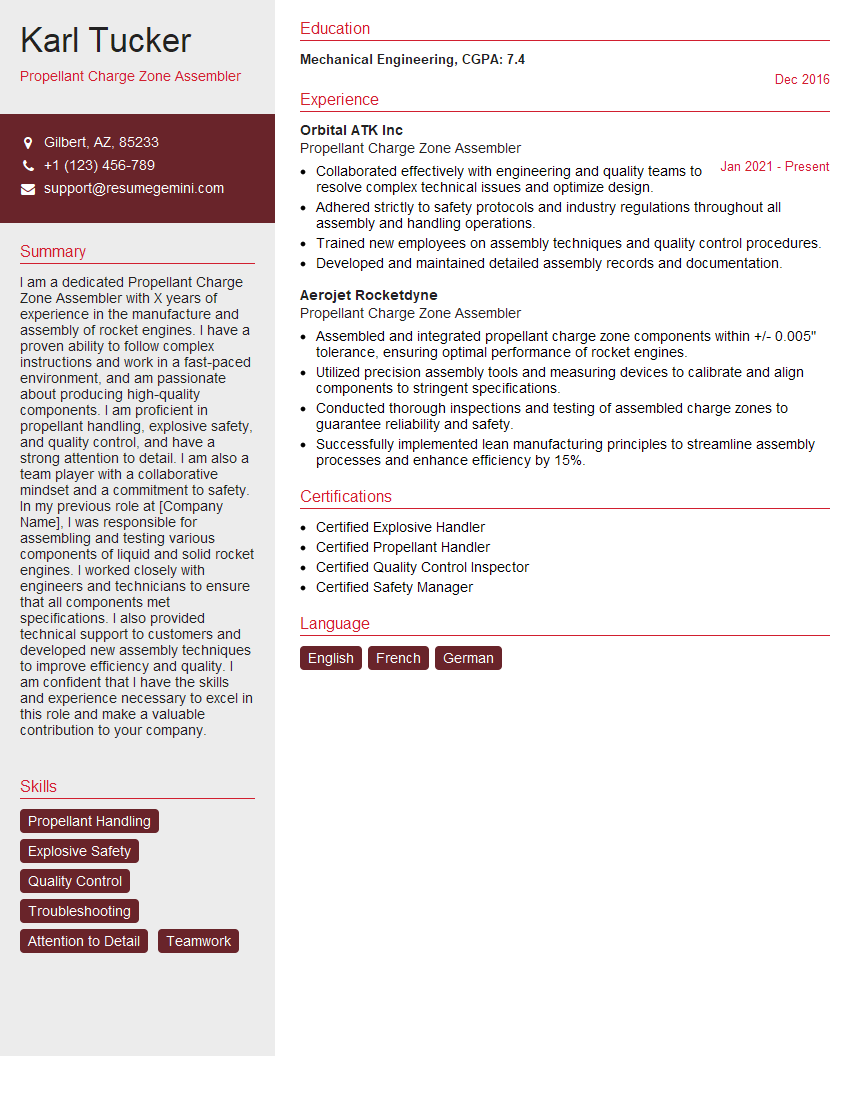

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Propellant Charge Zone Assembler

1. Describe the steps involved in assembling a propellant charge zone?

The steps involved in assembling a propellant charge zone are as follows:

- Prepare the propellant charge zone by inspecting it for any defects or damage.

- Install the igniter assembly into the propellant charge zone.

- Secure the igniter assembly to the propellant charge zone using bolts and nuts.

- Install the propellant grains into the propellant charge zone.

- Secure the propellant grains to the propellant charge zone using bolts and nuts.

- Install the nozzle assembly into the propellant charge zone.

- Secure the nozzle assembly to the propellant charge zone using bolts and nuts.

- Inspect the assembled propellant charge zone for any defects or damage.

- Test the assembled propellant charge zone to ensure it meets all specifications.

2. What are the safety precautions that must be followed when working with propellant charge zones?

The safety precautions that must be followed when working with propellant charge zones are as follows:

- Always wear appropriate personal protective equipment, such as gloves, safety glasses, and a lab coat.

- Do not smoke or eat in the work area.

- Keep the work area clean and free of debris.

- Do not store propellant charge zones in direct sunlight or near heat sources.

- Do not handle propellant charge zones roughly.

- Do not attempt to disassemble or modify propellant charge zones.

- If you have any questions or concerns, ask your supervisor for assistance.

3. What are the different types of propellant charge zones?

The different types of propellant charge zones are as follows:

- Solid propellant charge zones

- Liquid propellant charge zones

- Hybrid propellant charge zones

4. What are the advantages and disadvantages of each type of propellant charge zone?

Solid propellant charge zones

- Advantages:

- High energy density

- Long shelf life

- Reliable

- Disadvantages:

- Low specific impulse

- Difficult to control

- Can be hazardous

Liquid propellant charge zones

- Advantages:

- High specific impulse

- Easy to control

- Less hazardous than solid propellant charge zones

- Disadvantages:

- Lower energy density than solid propellant charge zones

- Shorter shelf life

- More complex to design and operate

Hybrid propellant charge zones

- Advantages:

- Combine the advantages of solid and liquid propellant charge zones

- Higher energy density than liquid propellant charge zones

- Longer shelf life than liquid propellant charge zones

- Less hazardous than solid propellant charge zones

- Disadvantages:

- More complex to design and operate than solid or liquid propellant charge zones

- Not as well-developed as solid or liquid propellant charge zones

5. What are the quality control procedures for propellant charge zones?

The quality control procedures for propellant charge zones are as follows:

- Inspect all materials and components for defects or damage.

- Follow all assembly procedures carefully.

- Test the assembled propellant charge zone to ensure it meets all specifications.

- Document all quality control procedures and results.

6. What are the troubleshooting procedures for propellant charge zones?

The troubleshooting procedures for propellant charge zones are as follows:

- Identify the problem.

- Determine the cause of the problem.

- Correct the problem.

- Test the propellant charge zone to ensure it is functioning properly.

7. What are the maintenance procedures for propellant charge zones?

The maintenance procedures for propellant charge zones are as follows:

- Inspect the propellant charge zone for any defects or damage.

- Clean the propellant charge zone.

- Lubricate the propellant charge zone.

- Test the propellant charge zone to ensure it is functioning properly.

8. What are the safety procedures for propellant charge zones?

The safety procedures for propellant charge zones are as follows:

- Always wear appropriate personal protective equipment, such as gloves, safety glasses, and a lab coat.

- Do not smoke or eat in the work area.

- Keep the work area clean and free of debris.

- Do not store propellant charge zones in direct sunlight or near heat sources.

- Do not handle propellant charge zones roughly.

- Do not attempt to disassemble or modify propellant charge zones.

- If you have any questions or concerns, ask your supervisor for assistance.

9. What are the environmental concerns associated with propellant charge zones?

The environmental concerns associated with propellant charge zones are as follows:

- Propellant charge zones can release harmful chemicals into the environment.

- Propellant charge zones can contribute to air pollution.

- Propellant charge zones can contaminate soil and water.

10. What are the future trends in propellant charge zone technology?

The future trends in propellant charge zone technology are as follows:

- Increased use of composite materials

- Development of new propellant formulations

- Improved manufacturing techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Propellant Charge Zone Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Propellant Charge Zone Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Propellant Charge Zone Assembler is responsible for assembling, inspecting, and testing various components of rocket propellant systems. They ensure that these components meet all specifications and perform as intended.

1. Assembly

Assembling propellant components is one of the primary responsibilities. This involves joining propellant grains, igniters, closures, and other hardware using specialized tools and techniques.

- Follow assembly procedures and blueprints to create propellant charge zones.

- Use precision measuring instruments and tools to ensure accuracy during assembly.

2. Inspection

Inspecting assembled components is crucial to ensure quality and safety. Assemblers visually examine and perform non-destructive tests to detect defects, deviations, or contamination.

- Conduct visual inspections to identify any visible flaws or imperfections.

- Utilize non-destructive testing methods, such as radiological or ultrasonic, to assess internal integrity.

3. Testing

Testing propellant charge zones is essential to verify their performance. Assemblers conduct functional tests to ensure that components operate correctly and meet specifications.

- Perform functional tests to assess ignition, burning rate, and pressure characteristics.

- Monitor test data and analyze results to identify any deviations or areas for improvement.

4. Documentation

Maintaining accurate records is crucial for quality control and traceability. Assemblers prepare assembly reports, inspection logs, and test results to document the assembly process and ensure compliance.

- Document assembly procedures, inspection findings, and test results according to established protocols.

- Maintain up-to-date records for traceability and quality assurance.

Interview Tips

Preparing for a Propellant Charge Zone Assembler interview requires a thorough understanding of the role and industry. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Research the company’s history, values, and specific requirements for the Propellant Charge Zone Assembler position. This demonstrates your interest and willingness to learn more about the organization.

- Review the company website and job description carefully.

- Search for news articles or industry publications about the company.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the job responsibilities. Quantify your accomplishments and provide specific examples of your work in assembly, inspection, and testing.

- Describe your experience in assembling and inspecting propellant components.

- Provide examples of successful tests you have conducted and the results achieved.

3. Show Enthusiasm for the Industry

Express your passion for the rocketry and propellant industries. Highlight your understanding of the critical role propellant charge zones play in rocket propulsion systems.

- Discuss your knowledge of different propellant types and their characteristics.

- Show your understanding of the safety aspects and regulations in the industry.

4. Prepare for Technical Questions

Prepare for technical questions related to assembly techniques, inspection methods, and testing procedures. Review industry standards and best practices to demonstrate your technical competence.

- Practice answering questions about assembly procedures and quality control.

- Be prepared to discuss your experience in using specific inspection and testing equipment.

5. Emphasize Attention to Detail

Highlight your attention to detail and commitment to quality. Explain how you ensure accuracy and consistency in your work, especially in critical areas.

- Describe your approach to meticulous assembly and inspection processes.

- Provide examples of how you identify and resolve potential issues during assembly.

6. Practice Common Interview Questions

Practice answering common interview questions such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses.” Prepare concise and compelling responses that highlight your suitability for the position.

- Tailor your responses to the specific requirements of the job description.

- Use the STAR method (Situation, Task, Action, Result) to provide structured and detailed answers.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Propellant Charge Zone Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Propellant Charge Zone Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.