Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Propeller Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Propeller Engineer so you can tailor your answers to impress potential employers.

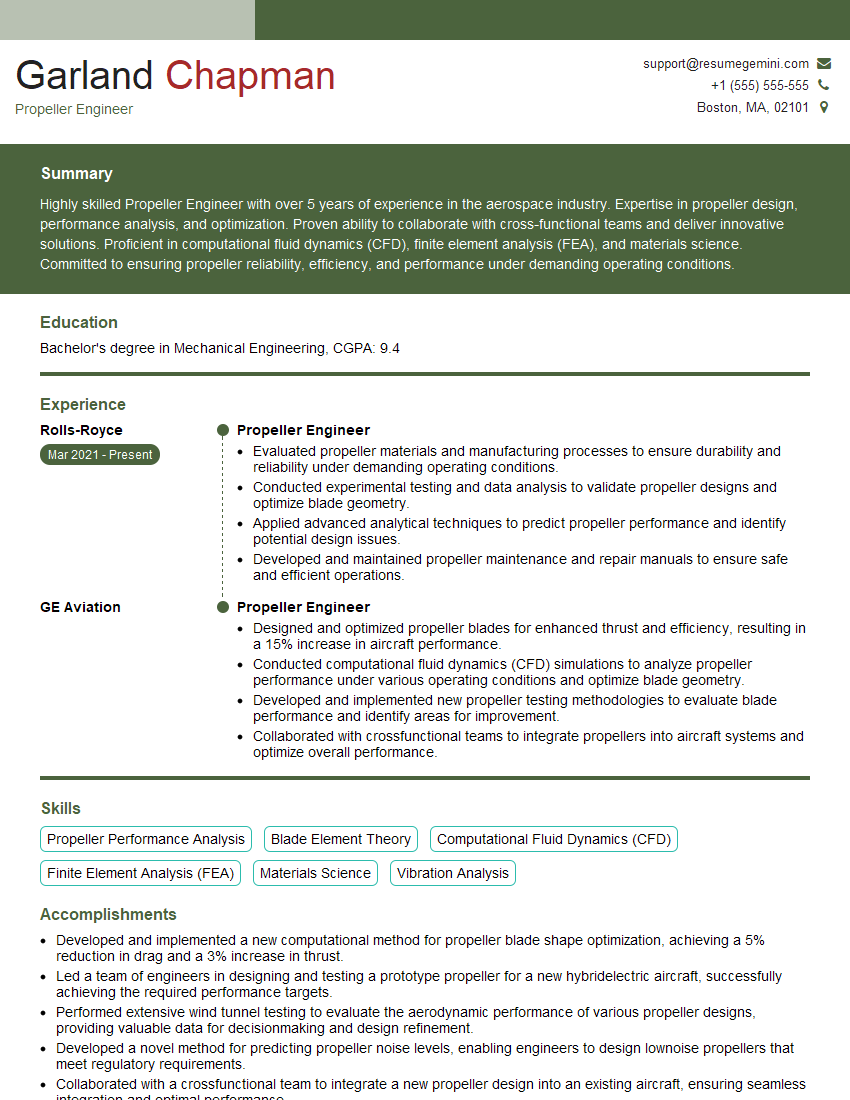

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Propeller Engineer

1. What are the different types of propellers and their applications?

- Fixed-pitch propellers are the most common type and are used on a wide range of aircraft, from small planes to large airliners.

- Variable-pitch propellers allow the pilot to change the pitch of the blades in flight, which can improve efficiency and performance.

- Counter-rotating propellers are used on some aircraft to reduce noise and improve efficiency.

2. What are the main factors that affect propeller performance?

Blade design

- The shape and size of the propeller blades will affect its efficiency, thrust, and noise.

- The number of blades on a propeller will also affect its performance.

Speed

- The speed of the propeller will affect its efficiency and thrust.

- The speed of the propeller is also limited by the speed of sound.

Angle of attack

- The angle of attack is the angle at which the propeller blades meet the air.

- The angle of attack will affect the propeller’s efficiency and thrust.

3. What are the different methods used to design propellers?

- Analytical methods use mathematical equations to calculate the performance of a propeller.

- Computational methods use computer simulations to calculate the performance of a propeller.

- Experimental methods use wind tunnel testing to measure the performance of a propeller.

4. What are the different types of materials used to make propellers?

- Aluminum alloys are the most common material used to make propellers.

- Composite materials are also used to make propellers, and they offer advantages such as reduced weight and improved durability.

- Steel and titanium are also used to make propellers, but they are less common than aluminum alloys and composite materials.

5. What are the different types of propeller failures and their causes?

- Blade bending or breakage can be caused by excessive loads, such as those encountered during takeoff or landing.

- Hub failure can be caused by fatigue or by excessive loads.

- Corrosion can also weaken propeller components and lead to failure.

6. What are the different types of propeller inspections and maintenance procedures?

- Visual inspections are used to look for cracks, corrosion, or other damage.

- Non-destructive testing methods, such as ultrasonic or eddy current testing, can be used to detect hidden damage.

- Propellers should be regularly balanced to ensure that they are operating smoothly and efficiently.

7. What are the different types of propeller control systems?

- Manual control systems allow the pilot to control the pitch of the propeller blades manually.

- Automatic control systems use sensors to automatically adjust the pitch of the propeller blades to maintain a desired engine speed or aircraft speed.

8. What are the different types of propeller thrust augmentation devices?

- Cowlings are used to improve the efficiency of the propeller by reducing drag.

- Spinners are used to reduce drag and improve the performance of the propeller at high speeds.

- Thrust reversers are used to direct the propeller thrust forward to slow down the aircraft.

9. What are the different types of propeller certification requirements?

- Propellers must be certified by the Federal Aviation Administration (FAA) before they can be installed on an aircraft.

- The FAA certification process includes testing the propeller to ensure that it meets all safety and performance requirements.

- Propellers must also be maintained in accordance with the manufacturer’s instructions.

10. What are the latest trends in propeller design and technology?

- Composite materials are becoming increasingly popular for propeller construction due to their light weight and improved durability.

- New propeller designs are being developed to improve efficiency and reduce noise.

- Advanced control systems are being developed to improve propeller performance and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Propeller Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Propeller Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Propeller Engineers are responsible for designing, testing, and analyzing propellers used in various marine and aerospace applications. They work closely with other engineers, scientists, and technicians to ensure that propellers meet the required specifications and performance criteria.

1. Propeller Design and Analysis

• Develop and analyze propeller designs using computational fluid dynamics (CFD) and other engineering tools.

• Optimize propeller geometry and performance to meet specific requirements, such as efficiency, thrust, and cavitation avoidance.

- Example: Conducting CFD simulations to determine the optimal blade shape and pitch for a new propeller design.

2. Testing and Evaluation

• Conduct physical tests on propellers in water tanks or wind tunnels to validate design concepts and performance.

• Analyze test data to identify areas for improvement and make necessary modifications to the propeller design.

- Example: Leading a team to conduct full-scale propeller tests in a water tank to measure thrust and efficiency.

3. Certification and Compliance

• Ensure that propellers meet all applicable industry standards and regulations for safety, efficiency, and environmental compliance.

• Collaborate with regulatory agencies and classification societies to obtain the necessary approvals and certifications.

- Example: Working with classification societies to obtain a propeller classification certificate for a new ship design.

4. Research and Development

• Conduct research and development activities to advance propeller technology and improve efficiency.

• Explore new materials, design concepts, and manufacturing techniques to enhance propeller performance.

- Example: Investigating the use of lightweight composite materials to reduce propeller weight and improve fuel efficiency.

Interview Tips

To ace the interview for a Propeller Engineer position, follow these tips:

1. Research the Company and Position

• Learn about the company’s products, services, and industry reputation.

• Review the job description thoroughly to understand the specific requirements and responsibilities.

- Example: Researching the latest advancements in propeller technology and their relevance to the company’s products.

2. Highlight Your Technical Skills and Experience

• Emphasize your proficiency in propeller design, analysis, and testing.

• Provide specific examples of projects where you demonstrated your technical abilities.

- Example: Quantifying the efficiency improvements achieved through your propeller design modifications.

3. Showcase Your Problem-Solving Abilities

• Demonstrate your ability to analyze problems, develop solutions, and implement them successfully.

• Use the STAR method (Situation, Task, Action, Result) to articulate your problem-solving approach.

- Example: Describing how you identified and resolved a cavitation issue on a propeller design using CFD simulations.

4. Emphasize Your Communication and Teamwork Skills

• Highlight your ability to communicate technical information effectively to both technical and non-technical audiences.

• Provide examples of successful collaborations with other engineers, scientists, and technicians.

- Example: Discussing your involvement in a cross-functional team that developed a new propeller prototype.

5. Prepare for Industry-Specific Questions

• Review common interview questions related to propeller design, analysis, and testing.

• Brush up on the latest industry trends and advancements in propeller technology.

- Example: Preparing for questions about the impact of additive manufacturing on propeller design and manufacturing.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Propeller Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.