Are you gearing up for a career in Propeller Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Propeller Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

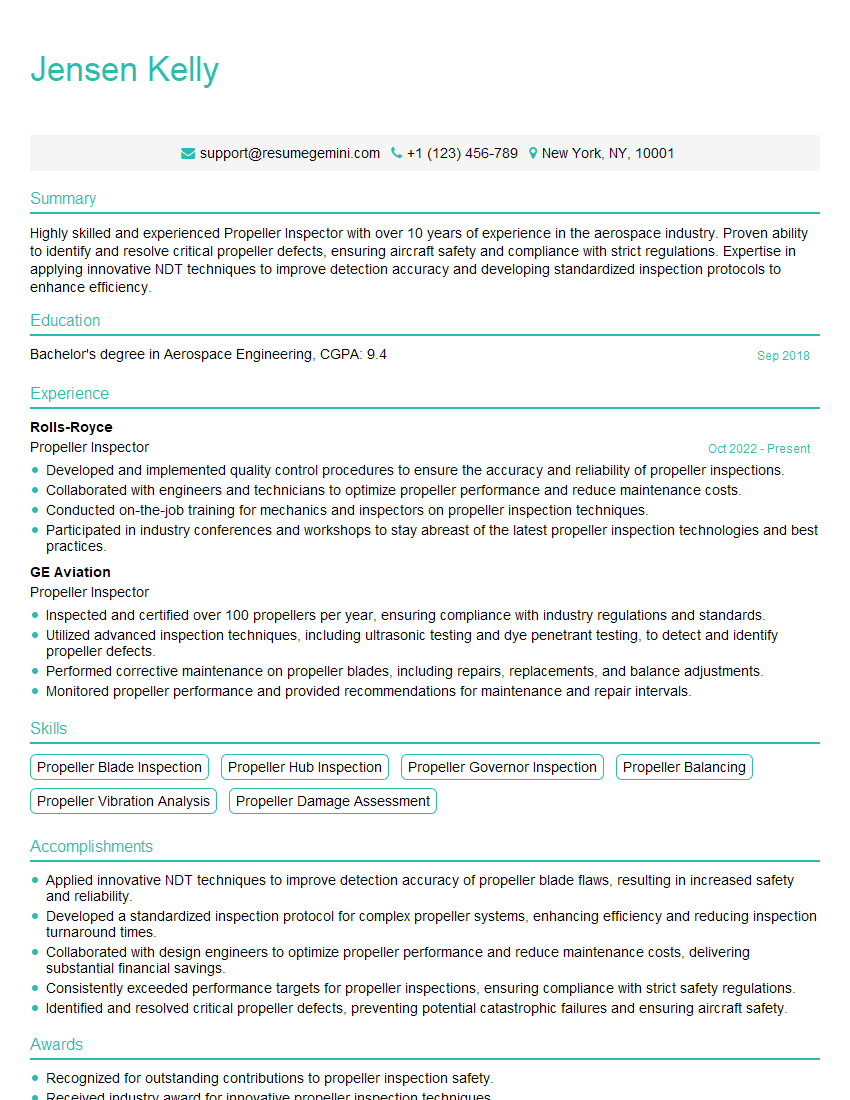

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Propeller Inspector

1. What are the key responsibilities of a Propeller Inspector?

The key responsibilities of a Propeller Inspector include:

- Inspecting and assessing the condition of propellers to ensure compliance with safety regulations and standards.

- Identifying and assessing damage and wear through visual and non-destructive testing methods.

- Determining propeller repairs and maintenance requirements and providing recommendations.

- Liaising with engineers, technicians, and other stakeholders to communicate inspection findings and provide technical support.

- Maintaining accurate records and documentation of inspections and findings.

2. Describe the different types of non-destructive testing (NDT) methods used in propeller inspection and their applications.

Visual Inspection

- Using a magnifying glass or borescope to examine the surface of the propeller for cracks, corrosion, or other defects.

- Dye penetrant testing to detect surface-breaking cracks.

Ultrasonic Testing

- Using high-frequency sound waves to detect internal defects, such as cracks or voids.

- Determine the thickness of the propeller blades.

Radiography

- Using X-rays or gamma rays to create images of the propeller’s internal structure.

- Detect internal defects, such as cracks, corrosion, or voids.

3. Explain the criteria used to assess the severity of propeller damage and the factors that influence repair or replacement decisions.

The severity of propeller damage is assessed based on the following criteria:

- Size and location of the damage.

- Type of damage (e.g., crack, corrosion, erosion).

- Structural integrity of the propeller.

- Propeller’s operational history and maintenance records.

Factors influencing repair or replacement decisions include:

- Cost of repair versus replacement.

- Availability of replacement propellers.

- Time constraints.

- Safety implications.

4. What are the common causes of propeller failure?

Common causes of propeller failure include:

- Mechanical damage, such as impact with objects or ground strikes.

- Fatigue damage due to repeated bending and twisting forces.

- Corrosion due to exposure to saltwater or other corrosive environments.

- Erosion due to cavitation or sandblasting.

- Manufacturing defects.

5. Describe the different types of propeller repair techniques and their advantages and disadvantages.

Welding

- Advantages: Strong and durable repair; can be used for most types of damage.

- Disadvantages: Can introduce heat distortion into the propeller; requires specialized equipment and skills.

Brazing

- Advantages: Less heat distortion than welding; suitable for repairing smaller cracks and defects.

- Disadvantages: Not as strong as welding; may not be suitable for all types of damage.

Metal stitching

- Advantages: Less heat distortion than welding or brazing; can be used for repairing larger cracks and defects.

- Disadvantages: Requires specialized equipment and skills; may not be suitable for all types of damage.

6. What are the quality control procedures involved in propeller inspection and repair?

Quality control procedures in propeller inspection and repair include:

- Establishing and adhering to written procedures and standards.

- Using calibrated and certified equipment.

- Performing regular inspections and audits.

- Maintaining accurate records and documentation.

- Providing training and certification for inspectors and technicians.

7. Explain the importance of balancing propellers and the methods used to achieve balance.

Balancing propellers is important to ensure smooth operation and prevent vibrations. Imbalance can cause excessive wear and damage to the propeller, shaft, and other components.

Methods used to achieve balance include:

- Static balancing: Measuring and adjusting the weight distribution of the propeller.

- Dynamic balancing: Measuring and adjusting the propeller’s rotation to minimize vibrations.

8. What are the safety precautions that must be observed when inspecting and repairing propellers?

Safety precautions when inspecting and repairing propellers include:

- Wearing appropriate personal protective equipment (PPE).

- Ensuring that the propeller is properly secured and supported.

- Using sharp tools and equipment with care.

- Avoiding contact with moving parts.

- Following established safety procedures and protocols.

9. Describe the role of documentation in propeller inspection and repair.

Documentation plays a vital role in propeller inspection and repair for several reasons:

- Provides a record of the inspections and repairs performed.

- Helps ensure that the work is done in accordance with procedures and standards.

- Facilitates communication between inspectors, technicians, and other stakeholders.

- Serves as evidence in the event of any disputes or legal proceedings.

10. How do you stay up-to-date with the latest technologies and best practices in propeller inspection and repair?

I stay up-to-date with the latest technologies and best practices in propeller inspection and repair through the following methods:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussion groups.

- Consulting with experts in the field.

- Receiving training from equipment manufacturers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Propeller Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Propeller Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Propeller Inspectors are responsible for inspecting, repairing, and maintaining propellers. They play a crucial role in ensuring the safety and efficiency of aircraft. Their key responsibilities include:

1. Inspecting Propellers

Inspect propellers for any damage, wear, or defects. Use a variety of inspection techniques, including visual inspection, borescope inspection, and ultrasonic inspection. Determine the extent of the damage and recommend appropriate repair or replacement options.

- Consistently examine the blades, hubs, and mounting systems of propellers

- Utilize specialized tools and equipment to detect cracks, corrosion, and other defects

2. Repairing and Maintaining Propellers

Repair or replace damaged propeller components. Use a variety of repair techniques, including welding, grinding, and riveting. Balance propellers to ensure smooth and efficient operation. Maintain propellers according to manufacturer’s specifications and industry standards.

- Conduct necessary repairs to restore propellers to optimal working condition

- Work with different materials like metal, composites, and fiberglass for repairs

3. Record Keeping and Documentation

Maintain detailed records of all inspections, repairs, and maintenance performed on propellers. Prepare and submit reports to supervisors and clients. Comply with all applicable regulations and standards.

- Meticulously document all inspection and repair activities in compliance with regulations

- Maintain accurate records for future reference and quality control purposes

4. Safety and Compliance

Follow all safety regulations and procedures. Wear appropriate protective gear and use proper tools and equipment. Comply with all applicable laws and regulations governing propeller inspection and repair.

- Prioritize safety by adhering to established protocols and industry best practices

- Stay updated on regulatory changes and ensure compliance to maintain safety standards

Interview Tips

Preparing thoroughly can increase your chances of success in the propeller inspector interview. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the propeller inspector position. This will enable you to tailor your answers and demonstrate your understanding of the role.

- Visit the company’s website, read industry news, and explore the job description thoroughly

- Identify the key responsibilities and skills required for the position

2. Practice Your Answers

Prepare for common interview questions related to propeller inspection, repair, and maintenance. Rehearse your answers to highlight your skills and experience. Practice with a friend or family member for feedback.

- Anticipate questions about your experience in inspecting, repairing, and maintaining propellers

- Craft clear and concise answers that showcase your knowledge and abilities

3. Highlight Your Experience and Skills

Emphasize your experience in propeller inspection and maintenance. Quantify your accomplishments using specific examples and metrics. Highlight your technical skills, such as welding, grinding, and riveting.

- Quantify your experience by providing specific numbers and results

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

4. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer. This demonstrates your interest in the position and the company. Ask about the company’s safety culture, training opportunities, and growth potential.

- Inquire about the company’s policies on safety and quality control

- Ask about opportunities for professional development and advancement within the organization

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Propeller Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.