Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Prototype Fabricator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Prototype Fabricator so you can tailor your answers to impress potential employers.

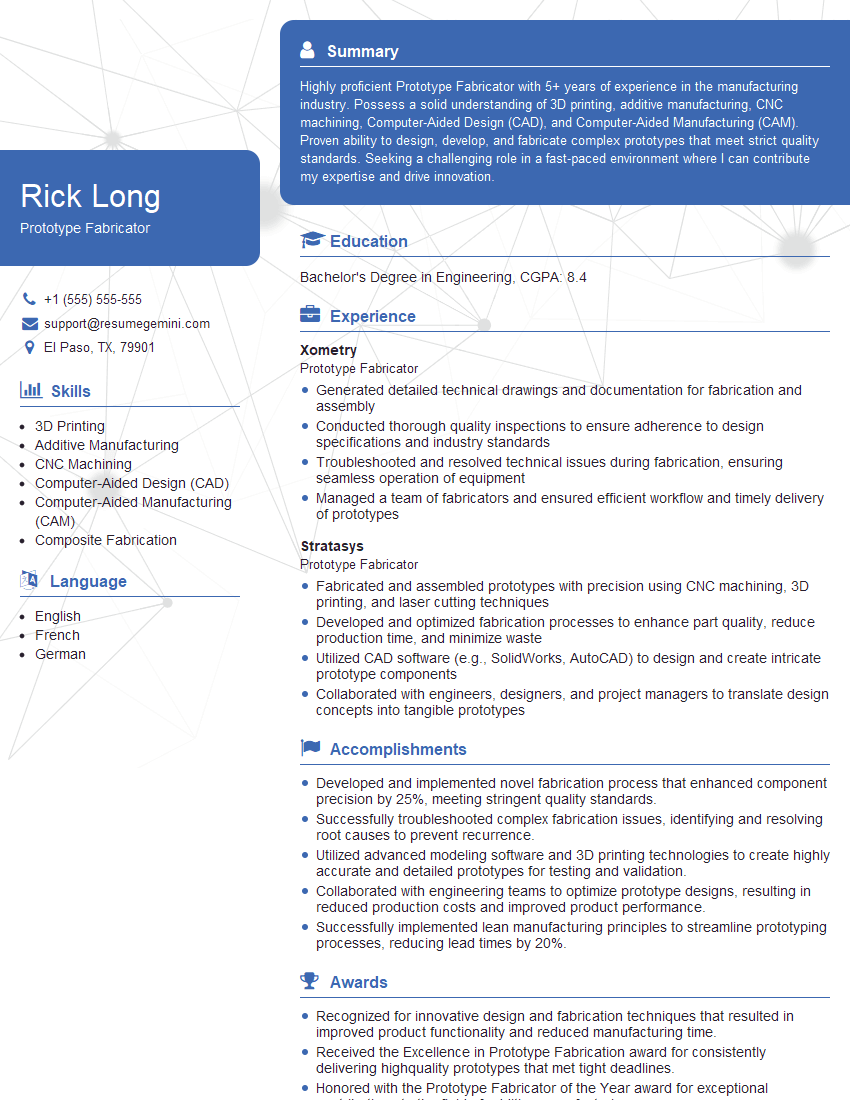

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Prototype Fabricator

1. Tell me about your experience in fabricating prototypes?

In my previous role as a Prototype Fabricator at XYZ Company, I was responsible for developing and constructing physical prototypes of new products. I worked closely with designers and engineers to understand the design specifications and transform those concepts into tangible prototypes.

2. What types of materials have you worked with as a Prototype Fabricator?

Metals

- Aluminum

- Steel

- Stainless Steel

- Titanium

Plastics

- ABS

- PC

- Nylon

- Polycarbonate

Composites

- Carbon Fiber

- Glass Fiber

- Kevlar

3. What are your strengths and weaknesses as a Prototype Fabricator?

Strengths

- Skilled in various fabrication techniques

- Strong attention to detail

- Ability to work independently and as part of a team

- Excellent problem-solving skills

Weaknesses

- Limited experience with certain materials

- Not an expert in CAD software

4. How do you stay updated with the latest fabrication techniques?

I attend industry conferences, read trade publications, and participate in online forums to stay abreast of the latest developments in fabrication technology. I am also eager to learn new techniques from experienced colleagues.

5. What is your approach to quality control in prototype fabrication?

Quality control is paramount in prototype fabrication. I follow a rigorous process that includes:

- Thorough inspection of materials

- Adherence to design specifications

- Testing prototypes to ensure functionality and durability

- Documentation of all quality control procedures

6. How do you collaborate with designers and engineers to ensure the successful completion of prototypes?

Effective collaboration is crucial. I actively seek input from designers and engineers throughout the fabrication process to ensure that the prototypes accurately reflect their design intent. I communicate regularly, address feedback promptly, and make adjustments as necessary to meet the project requirements.

7. Can you describe a complex prototype fabrication project you worked on?

Sure. In my previous role, I worked on a prototype for a new medical device. The device had intricate components that required precise fabrication techniques. I utilized a combination of CNC machining, laser cutting, and 3D printing to create the various parts. The final prototype met all the design specifications and functional requirements.

8. What are your expectations for this Prototype Fabricator role?

I am eager to contribute my skills and experience to your team. I am confident that I can deliver high-quality prototypes that meet your project requirements. I am also keen on learning new techniques and contributing to the company’s success.

9. What is your ideal work environment as a Prototype Fabricator?

I thrive in a dynamic and collaborative work environment where I can interact with designers, engineers, and other team members. Access to state-of-the-art fabrication equipment and a clean and organized workspace is also essential for me to perform my tasks effectively.

10. What are your salary expectations for this Prototype Fabricator position?

My salary expectations are commensurate with my experience, skills, and the industry standard for this position. I am open to discussing a competitive salary package that includes benefits such as health insurance, paid time off, and opportunities for professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Prototype Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Prototype Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Prototype Fabricator is a highly skilled craftsperson who is responsible for the creation of physical prototypes of products or components. They work from design specifications to create prototypes that are used for testing, evaluation, and marketing purposes.

1. Fabricate and Assemble Prototypes

Prototype Fabricators use a variety of materials and techniques to create prototypes. They may use 3D printing, CNC machining, welding, and other methods to create parts and components. They must be able to read and interpret engineering drawings and specifications, and they must be able to work independently and as part of a team.

2. Inspect and Test Prototypes

Once a prototype is fabricated, the Prototype Fabricator must inspect it for defects. They may also test the prototype to ensure that it meets the design specifications. They must be able to identify and correct any problems that are found.

3. Maintain Equipment

Prototype Fabricators must maintain the equipment that they use. This includes cleaning, lubricating, and calibrating the equipment. They must also be able to troubleshoot and repair any problems that occur.

4. Document Processes

Prototype Fabricators must document the processes that they use to create prototypes. This documentation may be used for training purposes or to help improve the efficiency of the prototyping process.

Interview Tips

Preparing for an interview for a Prototype Fabricator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position that you are applying for. This will help you to understand the company’s culture, its products or services, and the specific requirements of the job. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience as a Prototype Fabricator. Be prepared to talk about your experience in fabricating and assembling prototypes, inspecting and testing prototypes, maintaining equipment, and documenting processes.

4. Be Enthusiastic and Positive

The interviewer will be looking for someone who is enthusiastic about the position and who is positive about their ability to do the job. Be sure to show your enthusiasm and positivity throughout the interview.

5. Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is an opportunity for you to learn more about the company and the position, and to show the interviewer that you are interested in the job. Be sure to ask thoughtful questions that show that you have done your research and that you are excited about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Prototype Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!