Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Prototype Model Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

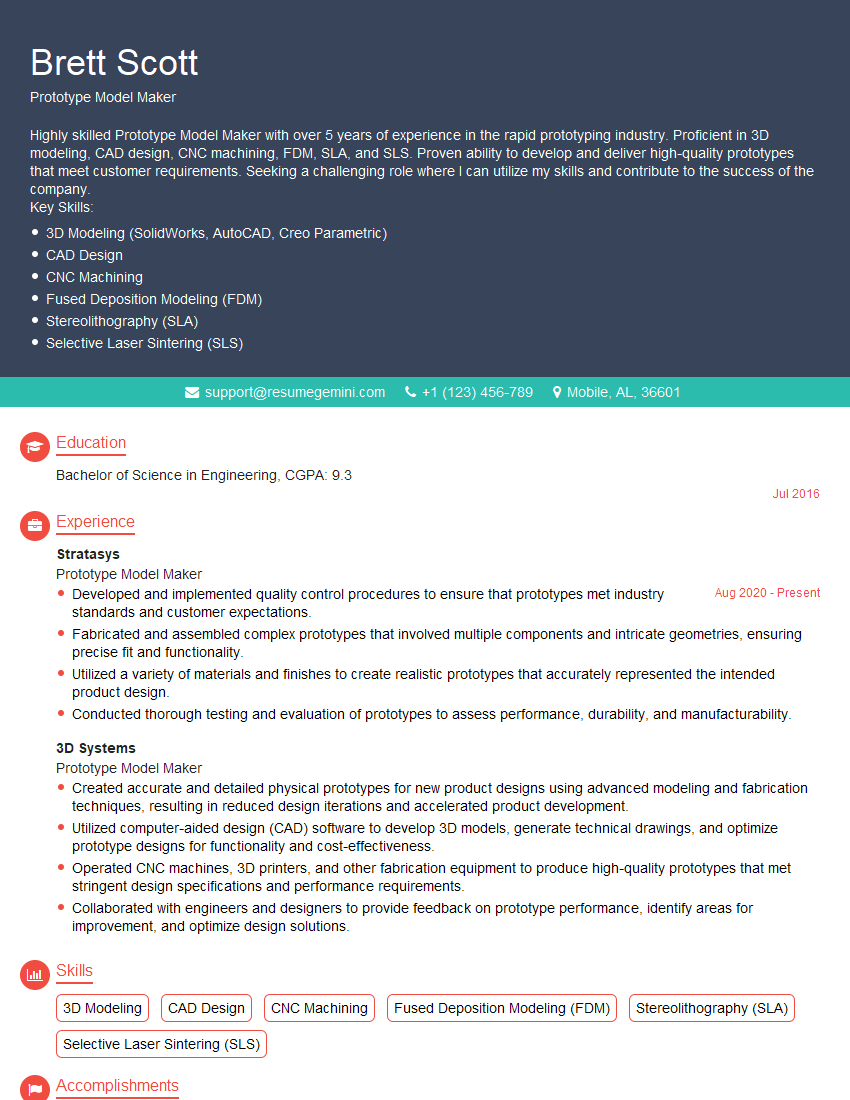

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Prototype Model Maker

1. How would you approach creating a prototype from a 2D design?

- Analyze the 2D design to understand its functionality, dimensions, and material requirements.

- Select appropriate materials and manufacturing techniques based on the design specifications.

- Create a 3D model using CAD software or other design tools.

- Use rapid prototyping or traditional machining techniques to produce the physical prototype.

- Test and refine the prototype to ensure it meets the desired specifications.

2. What factors do you consider when selecting materials for prototyping?

Strength and durability

- The intended use and load-bearing requirements of the prototype.

- The material’s tensile strength, yield strength, and other mechanical properties.

Cost and availability

- The budget for the prototyping project.

- The availability of the material in the required quantities and lead time.

Compatibility with manufacturing techniques

- The compatibility of the material with the chosen prototyping method (e.g., 3D printing, CNC machining).

- The machinability, moldability, or other properties relevant to the manufacturing process.

3. Describe the different types of rapid prototyping technologies you are familiar with.

- Stereolithography (SLA): Uses a laser to cure liquid resin layer by layer.

- Selective Laser Sintering (SLS): Uses a laser to fuse powder particles together.

- Fused Deposition Modeling (FDM): Extrudes molten material to create objects layer by layer.

- Multi-Jet Modeling (MJM): Jets photopolymer material and cures it with UV light.

- PolyJet Modeling: Similar to MJM, but uses a wider range of materials.

4. How do you ensure that your prototypes meet the required tolerances?

- Use accurate measurement tools and equipment (e.g., calipers, micrometers).

- Set up quality control procedures and inspections at critical stages of the prototyping process.

- Monitor and calibrate equipment regularly to maintain precision.

- Collaborate with designers to clarify specifications and tolerance requirements.

- Use software tools to analyze and optimize the design for manufacturability.

5. What is your approach to prototyping a complex assembly?

- Break down the assembly into individual components.

- Create prototypes of each component using appropriate materials and techniques.

- Assemble the prototype components to verify fit and functionality.

- Make adjustments or modifications as needed to ensure proper assembly.

- Test the assembled prototype to evaluate its overall performance.

6. How do you handle unforeseen challenges during the prototyping process?

- Stay calm and assess the situation.

- Identify the root cause of the issue through troubleshooting.

- Explore alternative solutions and consult with colleagues or experts if necessary.

- Document the problem and potential solutions.

- Make necessary adjustments to the design, materials, or manufacturing methods.

7. What is your experience with reverse engineering prototypes?

- Scan the original product using 3D scanning equipment.

- Create a 3D model of the scanned data using CAD software.

- Analyze the model to determine the design, materials, and manufacturing processes used.

- Create a prototype based on the reverse-engineered model.

- Test and refine the prototype to ensure it meets the desired specifications.

8. How do you maintain a clean and organized workspace?

- Follow established safety protocols.

- Keep tools and equipment in designated areas.

- Dispose of hazardous materials properly.

- Regularly clean up work surfaces and machines.

- Label and store materials appropriately.

9. What software tools do you use for prototyping?

- CAD software for 3D modeling (e.g., SolidWorks, AutoCAD).

- CAM software for generating toolpaths (e.g., Mastercam, HSMWorks).

- Simulation software for analyzing designs (e.g., ANSYS, COMSOL).

- Project management software for tracking progress and collaboration.

- CAM software for generating toolpaths (e.g., Mastercam, HSMWorks).

10. How do you stay up-to-date with the latest prototyping technologies and trends?

- Attend industry events and conferences.

- Read trade publications and online resources.

- Network with other professionals in the field.

- Experiment with new materials and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Prototype Model Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Prototype Model Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Prototype Model Maker is a highly skilled professional responsible for creating physical prototypes of products based on design specifications. Their primary duties involve:

1. Prototype Creation

Develop and build prototypes using a variety of materials and techniques, such as 3D printing, CNC machining, and manual fabrication.

- Interpret design specifications and translate them into physical models.

- Select appropriate materials and processes based on design requirements.

- Use precision tools and equipment to create high-quality prototypes.

2. Quality Assurance

Inspect prototypes thoroughly to ensure they meet design criteria and specifications.

- Conduct dimensional measurements and functional testing.

- Identify and correct any discrepancies or errors.

- Provide feedback to designers and engineers on prototype performance.

3. Communication and Collaboration

Work closely with designers, engineers, and other stakeholders to understand design requirements and provide updates on prototype progress.

- Attend design review meetings and provide input.

- Document prototype development and communicate findings.

- Maintain open communication to ensure prototypes align with project expectations.

4. Problem Solving and Innovation

Identify challenges during prototype creation and develop creative solutions to overcome them.

- Propose alternative materials or processes to enhance prototype accuracy or efficiency.

- Suggest design modifications to improve product functionality or manufacturability.

- Stay up-to-date on industry best practices and emerging technologies.

Interview Tips

Preparing thoroughly for a Prototype Model Maker interview will increase your chances of making a positive impression and landing the job:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture. Study the job description and identify the key qualifications and responsibilities.

- Visit the company website and social media pages.

- Read industry publications and articles.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Your Skills and Experience

Emphasize your technical expertise in prototype creation, quality assurance, and problem-solving. Showcase your ability to work independently and as part of a team.

- Quantify your accomplishments and provide specific examples of your work.

- Prepare a portfolio of your prototype designs and creations.

- Be prepared to discuss your knowledge of different fabrication techniques.

3. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice answering aloud to ensure clarity and avoid hesitation.

- Review the job description and identify potential questions related to your skills.

- Prepare examples of projects that demonstrate your abilities.

- Ask a friend or family member to conduct a mock interview.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview. Punctuality shows respect for the interviewer’s time.

- Choose clothing that is clean, pressed, and suited to a professional setting.

- Arrive at the interview location a few minutes early to avoid any delays.

- Be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Prototype Model Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!