Feeling lost in a sea of interview questions? Landed that dream interview for Puffer Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Puffer Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

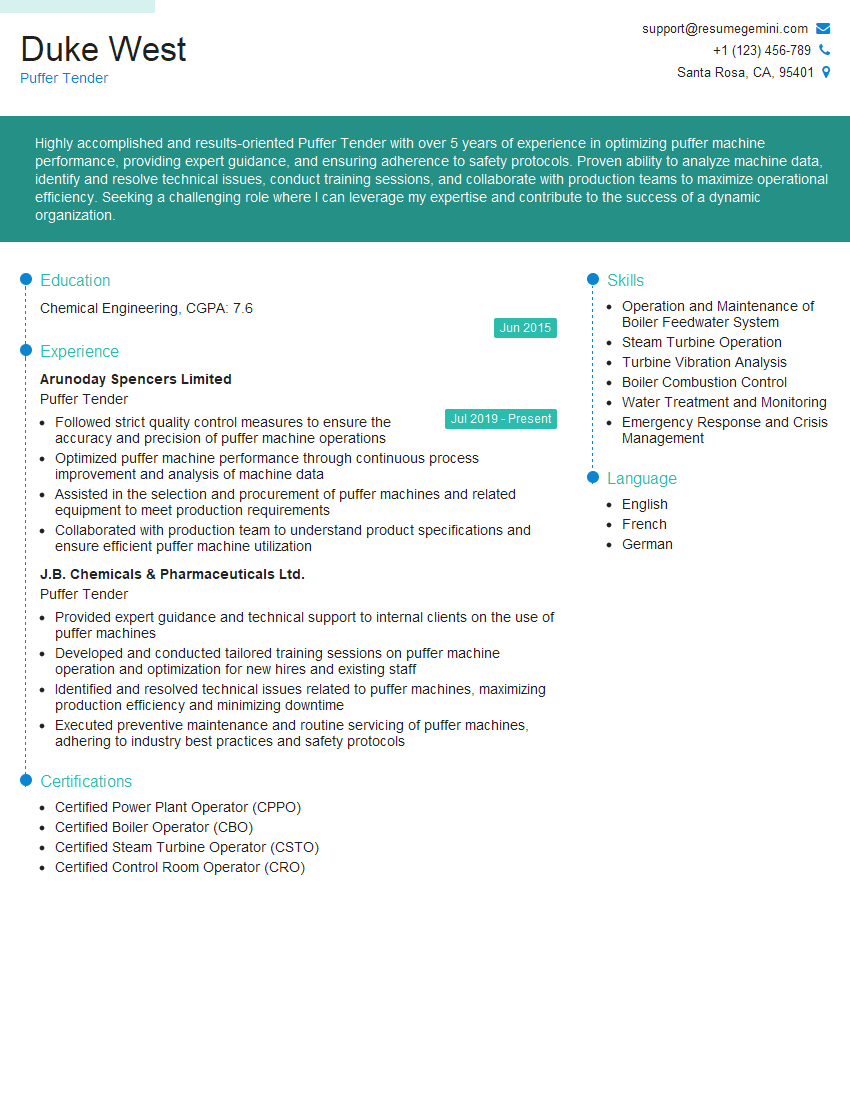

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Puffer Tender

1. Describe the purpose and function of a puffer tank?

A puffer tank is a device used in the shipbuilding and repair industry to create a temporary, enclosed, and inflatable environment within a compartment or space of a vessel. Its primary function is to provide a safe and controlled space for workers to perform tasks such as welding, painting, and cleaning in areas that are inaccessible or hazardous due to the presence of confined spaces, toxic fumes, or other safety concerns.

2. Explain the process of preparing a puffer tank for use, including safety precautions and equipment required?

Safety Precautions:

- Ensure proper ventilation to prevent the accumulation of toxic fumes.

- Wear appropriate protective gear, including respirators, gloves, and eye protection.

- Inspect the puffer tank for any damage or leaks before use.

- Follow established safety protocols and guidelines.

Equipment Required:

- Puffer tank and blower

- Air supply and hoses

- Clips or clamps to secure the tank in place

- Lights and electrical equipment for illumination

- Tools and materials required for the specific task

3. How do you maintain and troubleshoot a puffer tank during operations?

During operations, it is crucial to maintain the integrity and functionality of the puffer tank. Regular maintenance includes checking for leaks, ensuring proper air pressure, and inspecting the blower for proper operation. Troubleshooting involves identifying potential issues, such as air leaks, blower malfunctions, or power supply problems. Prompt repairs or adjustments should be made to maintain a safe and effective working environment.

4. Describe the different types of materials used for puffer tank construction and their respective advantages and disadvantages?

Puffer tanks are typically constructed using various materials, each with its unique advantages and disadvantages. Common materials include:

- PVC (Polyvinyl chloride): Lightweight, flexible, and durable, PVC is commonly used for smaller tanks due to its ease of handling and installation.

- PU (Polyurethane): Known for its high strength, abrasion resistance, and chemical resistance, PU is suitable for heavy-duty applications and harsh environments.

- Rubber: Provides excellent air retention and flexibility, making it suitable for complex shapes and confined spaces. However, it can be more expensive than other materials.

5. Explain the importance of proper ventilation and air supply when working with a puffer tank?

Adequate ventilation and air supply are critical for the safety of workers using a puffer tank. The purpose of ventilation is to prevent the accumulation of toxic fumes and ensure a fresh air supply within the enclosed space. Proper air supply maintains the required pressure inside the tank, creating a positive pressure environment that prevents outside contaminants from entering the work area. This helps protect workers from exposure to hazardous substances and ensures a safe and healthy working environment.

6. Describe the emergency procedures to follow in case of a puffer tank failure or malfunction?

In the event of a puffer tank failure or malfunction, it is crucial to follow established emergency procedures to ensure the safety of workers and minimize potential hazards. These procedures may include:

- Immediately evacuate all workers from the affected area.

- Identify the source of the failure or malfunction and take steps to isolate it.

- Contact the supervisor or designated emergency personnel for assistance.

- Ventilate the affected area to remove any accumulated fumes or gases.

- Do not re-enter the area until it has been deemed safe by authorized personnel.

7. What are the key safety regulations and industry standards applicable to the use of puffer tanks?

The use of puffer tanks must adhere to various safety regulations and industry standards to ensure the safety of workers and compliance with legal requirements. These regulations may include:

- Occupational Safety and Health Administration (OSHA) regulations

- American Welding Society (AWS) standards

- National Fire Protection Association (NFPA) codes

- Specific regulations or guidelines set by the shipyard or employer

Compliance with these regulations is crucial to minimize risks, prevent accidents, and ensure a safe work environment.

8. What are the common challenges faced while working with puffer tanks and how do you overcome them?

Working with puffer tanks can present various challenges, including:

- Confined spaces: Working in a confined space within the tank requires proper ventilation and safety measures.

- Air leaks: Maintaining a consistent air supply and pressure is crucial to prevent collapse or deformation of the tank.

- Toxic fumes: Welding, painting, or other activities within the tank can generate hazardous fumes, necessitating proper ventilation and respiratory protection.

- Electrical hazards: Lighting and equipment used within the tank must be properly grounded and protected against moisture.

To overcome these challenges, it is important to follow safety protocols, use proper equipment, maintain regular maintenance, and have a contingency plan in place for emergencies.

9. How do you coordinate with other team members when working on a project involving a puffer tank?

Effective coordination is vital when working with puffer tanks on a project. Communication and teamwork are essential to ensure a safe and efficient work environment. Responsibilities may include:

- Communicating safety protocols and procedures to all involved team members.

- Assigning roles and responsibilities for tank setup, maintenance, and monitoring.

- Coordinating with ventilation and electrical personnel to ensure a safe and well-ventilated work area.

- Maintaining regular communication to address any issues or concerns that arise during the project.

10. Describe a specific project where you successfully utilized a puffer tank and the key challenges you encountered?

In a recent shipyard project, I was responsible for using a puffer tank to create a controlled environment for welding repairs on a large cargo vessel. The key challenges included:

- Confined space: The work area within the tank was narrow and required careful planning for ventilation and worker access.

- Toxic fumes: Welding created significant fumes, necessitating the use of respirators and a constant supply of fresh air.

- Air leaks: Maintaining a consistent air pressure inside the tank was crucial to prevent its collapse during welding.

To overcome these challenges, I worked closely with the ventilation team to ensure proper air circulation and monitored the air pressure regularly. I also implemented a safety protocol for entering and exiting the tank to minimize the risk of exposure to fumes. The project was successfully completed within the specified timeframe, maintaining the highest safety standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Puffer Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Puffer Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Puffer Tender is responsible for the operation and maintenance of a steam-powered boiler. The key responsibilities of this role include:

1. Boiler Operation

The Puffer Tender is responsible for the safe and efficient operation of the boiler. This includes starting, stopping, and controlling the boiler’s temperature and pressure. The Puffer Tender must also be able to identify and correct any problems with the boiler’s operation.

- Starting, stopping, and controlling the boiler’s temperature and pressure

- Identifying and correcting any problems with the boiler’s operation

- Monitoring the boiler’s water level and pressure

- Adjusting the boiler’s controls to maintain the desired temperature and pressure

2. Boiler Maintenance

The Puffer Tender is also responsible for the maintenance of the boiler. This includes cleaning, inspecting, and repairing the boiler. The Puffer Tender must be able to identify and correct any problems with the boiler’s maintenance.

- Cleaning the boiler

- Inspecting the boiler for any damage or wear

- Repairing the boiler as needed

- Performing preventive maintenance on the boiler

3. Water Treatment

The Puffer Tender is also responsible for the treatment of the boiler’s water. This includes adding chemicals to the water to prevent corrosion and scale buildup. The Puffer Tender must be able to test the water’s quality and adjust the chemical treatment as needed.

- Adding chemicals to the boiler’s water to prevent corrosion and scale buildup

- Testing the water’s quality

- Adjusting the chemical treatment as needed

- Monitoring the boiler’s water level

4. Safety

The Puffer Tender is responsible for the safety of the boiler and the work area. This includes following all safety procedures and regulations. The Puffer Tender must also be able to identify and correct any safety hazards.

- Following all safety procedures and regulations

- Identifying and correcting any safety hazards

- Wearing appropriate personal protective equipment

- Keeping the work area clean and organized

Interview Tips

To ace the interview for a Puffer Tender position, you should:

1. Research the Company and the Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture and the requirements of the job. You can research the company’s website, read industry news, and talk to people who work there.

- Research the company’s website.

- Read industry news.

- Talk to people who work there.

2. Practice Your Answers

Once you’ve researched the company and the position, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview. You can practice with a friend, family member, or career counselor.

- Practice with a friend, family member, or career counselor.

- Focus on your skills and experience.

- Be prepared to talk about your strengths and weaknesses.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire. You should also be well-groomed and have clean shoes.

- Wear a suit or business casual attire.

- Be well-groomed.

- Have clean shoes.

4. Be Punctual

Punctuality shows that you’re respectful of the interviewer’s time. Arrive for your interview on time, or even a few minutes early. This will show that you’re organized and punctual.

- Arrive for your interview on time.

- Give yourself plenty of time to get to the interview location.

- If you’re running late, call or email the interviewer to let them know.

5. Be Enthusiastic and Positive

Interviewers want to hire people who are enthusiastic and positive. Show the interviewer that you’re excited about the opportunity to work for the company. Be positive and upbeat throughout the interview.

- Show the interviewer that you’re excited about the opportunity to work for the company.

- Be positive and upbeat throughout the interview.

- Smile and make eye contact with the interviewer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Puffer Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Puffer Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.