Are you gearing up for a career in Pull Over Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pull Over Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

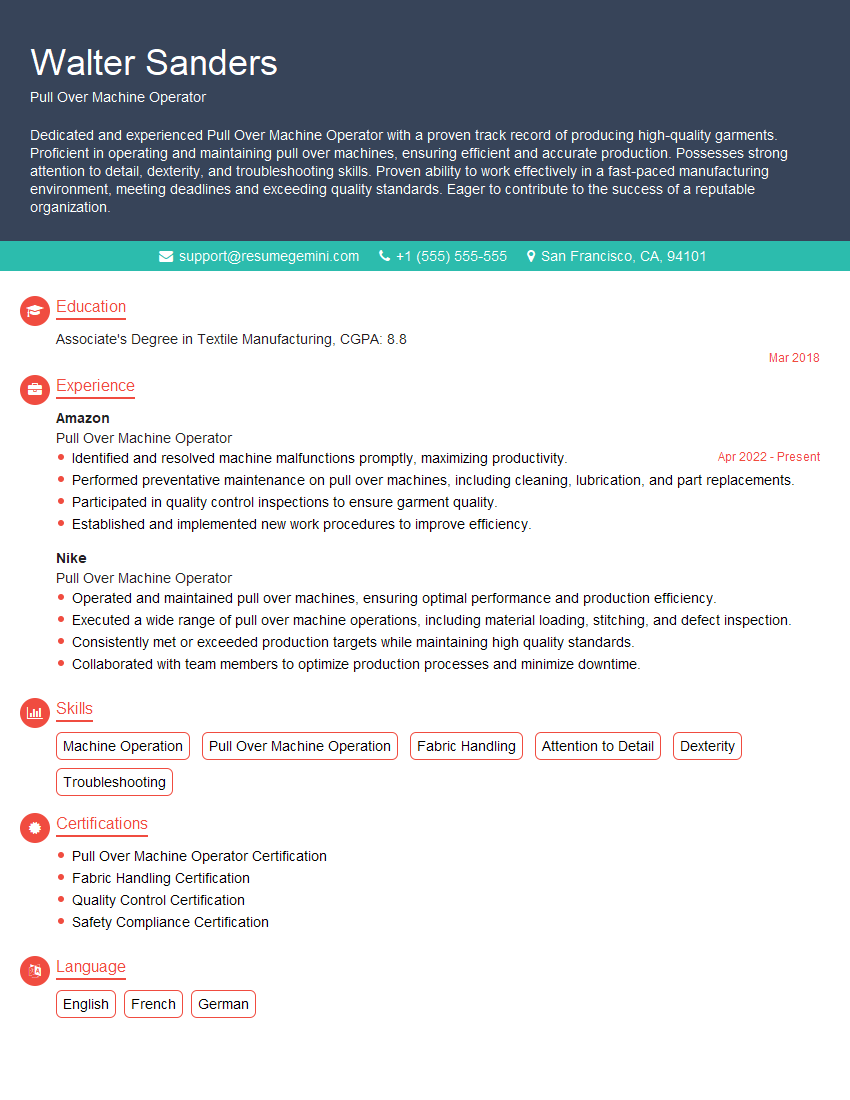

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pull Over Machine Operator

1. What are the key responsibilities of a Pull Over Machine Operator?

As a Pull Over Machine Operator, my primary responsibilities encompass:

- Loading and unloading fabric onto the pull over machine

- Operating the machine to pull fabric over frames

- Monitoring the machine and ensuring that it is running smoothly

- Inspecting the fabric for defects and removing any damaged pieces

- Making adjustments to the machine as needed to ensure optimal performance

- Maintaining a clean and organized work area

2. Describe the safety precautions that must be taken when operating a Pull Over Machine?

General Safety Measures

- Wear appropriate safety gear, including gloves and safety glasses

- Ensure the machine is properly grounded to prevent electrical hazards

- Keep the work area clean and free of debris

- Be aware of moving parts and keep hands and clothing away from them

Machine-Specific Precautions

- Follow the manufacturer’s instructions for operating the machine

- Inspect the machine before each use and report any problems to a supervisor

- Never attempt to repair the machine yourself

- Stop the machine immediately if any unusual noises or vibrations occur

3. How do you troubleshoot common problems that may arise with a Pull Over Machine?

To troubleshoot common problems with a pull over machine, I follow a systematic approach:

- Identify the problem and its symptoms

- Inspect the machine for any obvious issues, such as loose connections or damaged parts

- Refer to the manufacturer’s troubleshooting guide for specific instructions

- If the problem persists, contact a qualified technician for assistance

4. What maintenance tasks are required to keep a Pull Over Machine in good working condition?

Regular maintenance is crucial for keeping a pull over machine in optimal condition:

- Daily: Check and clean the machine, lubricate moving parts

- Weekly: Inspect the machine for worn or damaged parts

- Monthly: Perform a thorough cleaning and inspection, replace filters

- Quarterly: Conduct a comprehensive inspection by a qualified technician

5. How do you ensure that the fabric is properly pulled over the frames?

To ensure proper pulling, I:

- Inspect the fabric for defects and remove any damaged pieces

- Load the fabric onto the machine evenly and securely

- Set the machine to the correct settings for the fabric type

- Monitor the machine during operation and make adjustments as needed

- Inspect the pulled fabric for any defects or wrinkles

6. Describe the different types of fabrics that can be used with a Pull Over Machine?

Pull over machines can accommodate a wide range of fabrics, including:

- Woven fabrics: cotton, linen, silk

- Knitted fabrics: jersey, rib, interlock

- Non-woven fabrics: felt, fleece

7. How do you handle fabric defects or tears that occur during the pull over process?

If I encounter fabric defects or tears, I:

- Stop the machine immediately

- Remove the damaged fabric from the machine

- Inspect the fabric to determine the extent of the damage

- If the damage is minor, I repair it using a sewing machine or fabric glue

- If the damage is extensive, I discard the fabric and restart the process with a new piece of fabric

8. What is the maximum fabric width that can be handled by a Pull Over Machine?

The maximum fabric width that can be handled by a pull over machine depends on the specific model and manufacturer. Common maximum widths range from:

- 160 centimeters (63 inches)

- 180 centimeters (71 inches)

- 200 centimeters (79 inches)

9. How do you maintain a consistent pulling tension throughout the process?

To maintain consistent pulling tension, I:

- Calibrate the machine regularly using a tension gauge

- Inspect the fabric for variations in thickness or weave

- Adjust the machine settings as needed to ensure proper tension

- Monitor the machine during operation and make adjustments as necessary

10. Describe the different frame sizes that can be used with a Pull Over Machine?

Pull over machines can accommodate a variety of frame sizes, including:

- Standard frames: 60 x 90 centimeters (24 x 36 inches)

- Oversized frames: 90 x 120 centimeters (36 x 48 inches)

- Custom frames: Available in various sizes to meet specific requirements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pull Over Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pull Over Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pull Over Machine Operator is accountable for the skillful operation of the pull over machine, which is utilized in various industries to shape and form different types of materials.

1. Oversee Machine Operation

The operator is responsible for the efficient operation of the pull over machine, ensuring that it functions smoothly and effectively to produce high-quality products. They are expected to monitor the machine’s performance, make necessary adjustments, and troubleshoot any technical issues.

2. Set Up and Adjust Machine

Prior to operating the machine, the operator must prepare it by setting up the necessary parameters and adjusting settings based on the specific requirements of the production process. This involves determining the correct temperature, speed, and pressure settings for optimal operation.

3. Load and Unload Materials

The operator is responsible for loading raw materials into the machine and unloading finished products. This process may involve manual handling or the use of automated systems, depending on the specific equipment and production environment.

4. Maintain and Clean Machine

To ensure the longevity and optimal performance of the pull over machine, the operator is responsible for routine maintenance and cleaning tasks. This includes inspecting the machine for any wear or damage, lubricating moving parts, and cleaning the machine’s surfaces to prevent contamination.

Interview Tips

Preparing for an interview for a Pull Over Machine Operator position requires thorough research and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to learn about the company’s history, values, and industry standing. Additionally, familiarize yourself with the specific job requirements, including the responsibilities and qualifications necessary for the role.

2. Practice Common Interview Questions

Prepare for common interview questions by rehearsing your answers in advance. Consider questions related to your technical expertise, experience operating similar machinery, and your approach to problem-solving.

3. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job requirements. Provide concrete examples of your ability to operate and maintain pull over machines, as well as your problem-solving abilities.

4. Demonstrate Enthusiasm and Professionalism

Convey your enthusiasm for the role and the opportunity to contribute to the company’s success. Maintain a professional demeanor throughout the interview, dress appropriately, and arrive on time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pull Over Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pull Over Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.