Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pulley Maintainer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

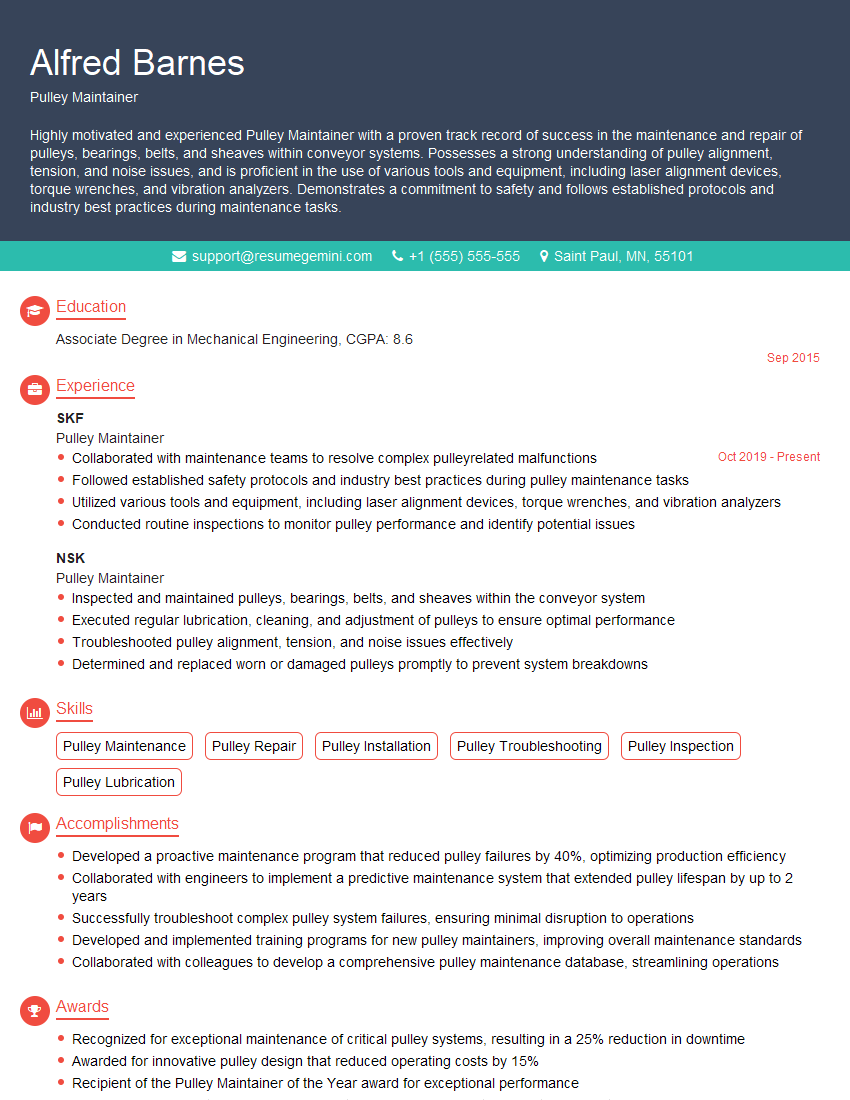

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulley Maintainer

1. How do you inspect pulleys for wear and tear?

- Visually inspect the pulley for any cracks, chips, or other damage.

- Check the pulley for any signs of wear, such as grooves or flat spots.

- Measure the pulley’s diameter to ensure that it is within the manufacturer’s specifications.

- Check the pulley’s bearings for any signs of wear or damage.

- Listen for any unusual noises when the pulley is in operation.

2. What are the different types of pulleys and what are their applications?

Fixed Pulleys

- Do not move and are used to change the direction of a force.

- Examples: flagpoles, window blinds

Movable Pulleys

- Move with the rope and are used to lift heavy objects.

- Examples: cranes, elevators

Compound Pulleys

- Combine fixed and movable pulleys to create a mechanical advantage.

- Examples: block and tackle systems

3. How do you lubricate pulleys?

- Clean the pulley with a degreaser to remove any dirt or debris.

- Apply a thin layer of lubricant to the pulley’s bearings.

- Wipe off any excess lubricant.

- Allow the lubricant to dry completely before operating the pulley.

4. What are the safety precautions that you should take when working with pulleys?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Inspect the pulley and the rope before using it.

- Do not overload the pulley.

- Do not use a pulley that is damaged or has worn bearings.

- Be aware of the surroundings and keep people clear of the area where the pulley is being used.

5. How do you troubleshoot a pulley that is not working properly?

- Inspect the pulley for any damage or wear.

- Check the rope for any damage or wear.

- Lubricate the pulley’s bearings.

- Adjust the tension on the rope.

- Replace the pulley or the rope if necessary.

6. What are the different types of materials that pulleys are made of?

- Metal (steel, aluminum)

- Plastic

- Wood

- Composite materials

7. What are the different types of bearings that are used in pulleys?

- Plain bearings

- Ball bearings

- Roller bearings

- Needle bearings

8. What are the factors that you consider when selecting a pulley for a particular application?

- The size of the load

- The speed of the load

- The environment in which the pulley will be used

- The cost of the pulley

9. What are the different types of sheaves that are used in pulleys?

- V-groove sheaves

- U-groove sheaves

- Flat sheaves

10. What is the difference between a idler pulley and a tension pulley?

- Idler pulleys

- Do not provide any mechanical advantage.

- Used to change the direction of a belt or rope.

- Tension pulleys

- Provide tension to a belt or rope.

- Used to prevent a belt or rope from slipping.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulley Maintainer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulley Maintainer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pulley Maintainer is primarily responsible for the upkeep, repair, and optimal performance of pulleys and associated equipment within a variety of industrial settings. Key job responsibilities include:1. Pulley Maintenance and Repair

Inspecting, cleaning, lubricating, and adjusting pulleys to ensure smooth operation.

- Identifying and diagnosing pulley malfunctions, such as misalignment, worn bearings, and loose or broken parts.

- Disassembling, repairing, and reassembling pulleys using specialized tools and techniques.

- Conducting regular maintenance checks to prevent breakdowns and ensure longevity.

2. Rope and Cable Management

Inspecting and replacing ropes and cables connected to pulleys for signs of wear, fraying, or damage.

- Determining appropriate rope and cable sizes, materials, and tension levels.

- Ensuring proper installation, routing, and tensioning of ropes and cables to maximize efficiency and safety.

- Troubleshooting and resolving issues related to rope and cable performance.

3. Equipment Monitoring and Analysis

Monitoring the performance of pulleys and associated equipment using specialized instruments and techniques.

- Analyzing data collected from sensors, gauges, and other equipment to identify potential problems or areas for improvement.

- Making adjustments to pulley settings or operating parameters to optimize performance and efficiency.

- Reporting on equipment condition, maintenance activities, and potential risks to supervisors or management.

4. Safety Compliance and Training

Ensuring adherence to safety regulations and protocols related to pulley maintenance and operation.

- Identifying and mitigating potential hazards associated with pulley systems.

- Participating in safety training programs and staying up-to-date on industry best practices.

- Training and instructing other personnel on proper pulley maintenance and safety procedures.

Interview Tips

Preparing thoroughly for a Pulley Maintainer interview is crucial for success. Here are some tips to help you ace the interview:1. Research the Company and Industry

Conduct thorough research on the company you are interviewing with, their products or services, and the industry in which they operate.

- This demonstrates your interest in the company and the role, and shows that you have taken the time to understand their business.

- Use the company’s website, industry publications, and social media to gather relevant information.

2. Practice Your Skills and Experience

Review your resume and identify the key skills and experiences that are relevant to the Pulley Maintainer role.

- Prepare examples of your past work experience that demonstrate your abilities in pulley maintenance, repair, and troubleshooting.

- Be able to articulate your knowledge of pulley systems, rope and cable management, and safety protocols.

3. Prepare for Common Interview Questions

Research common interview questions asked for Pulley Maintainer positions and prepare thoughtful responses.

- For example, you may be asked about your experience with specific pulley types, troubleshooting techniques, or safety procedures.

- Practice answering these questions clearly and concisely, highlighting your skills and experience.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview punctually.

- This shows respect for the interviewer and demonstrates your attention to detail.

- Plan your route and allow yourself ample time to avoid any unexpected delays.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pulley Maintainer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pulley Maintainer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.