Are you gearing up for a career in Pulling Unit Floorhand? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pulling Unit Floorhand and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

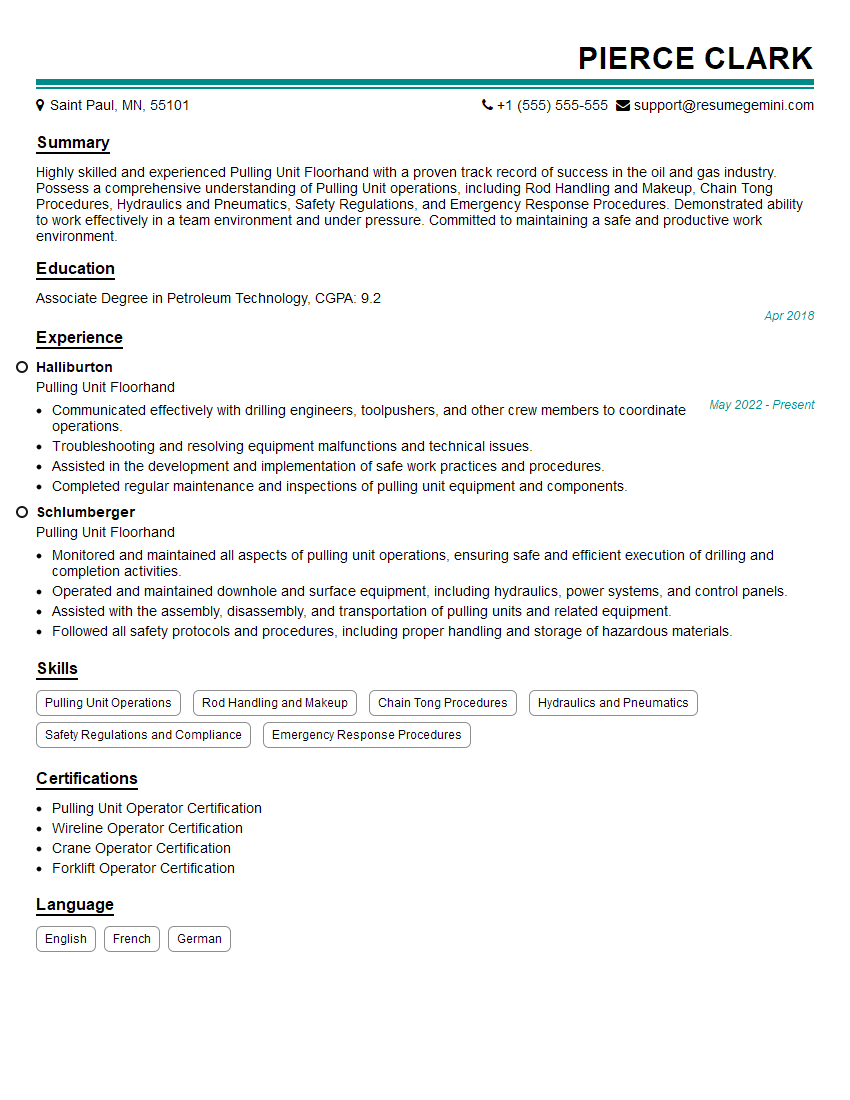

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulling Unit Floorhand

1. Can you describe the steps involved in performing an installation and start-up of a pulling unit?

In an installation and start-up of a pulling unit, I follow these steps:

- Conduct a thorough site assessment and prepare the work area.

- Unload and position the pulling unit using appropriate lifting equipment.

- Assemble and install the unit according to the manufacturer’s specifications, ensuring proper alignment and leveling.

- Connect all necessary piping, electrical, and hydraulic components.

- Perform a thorough inspection and pressure test of the system.

- Commission the pulling unit, verify its functionality, and conduct performance tests.

- Train the operating personnel on safe operation and maintenance procedures.

2. Explain the principles of operation of a pulling unit.

Mechanical System

- The pulling unit employs a winch or hydraulic cylinder to apply force to the pulling line.

- The line is attached to the load, which is then pulled or lifted.

- Gears, chains, and pulleys transfer power from the prime mover to the winch or cylinder.

Hydraulic System

- Hydraulic fluid is pumped through a system of valves and hoses.

- The pressure in the system is controlled to provide the necessary force to operate the cylinder.

- The cylinder extends or retracts, pulling or lifting the load.

3. What are the common safety hazards associated with operating a pulling unit and how do you mitigate them?

Common safety hazards associated with operating a pulling unit include:

- Falling objects: Secure all tools, equipment, and materials to prevent them from falling.

- Pinch points: Be aware of pinch points between moving parts and avoid contact.

- Electrical hazards: Follow proper electrical safety protocols and use grounded equipment.

- Hydraulic pressure: Ensure hydraulic lines and components are properly maintained and free of leaks.

- Overhead hazards: Be aware of overhead power lines and other obstructions.

4. How do you maintain and troubleshoot a pulling unit?

To maintain and troubleshoot a pulling unit, I:

- Conduct regular inspections and preventive maintenance tasks, such as lubrication and fluid checks.

- Monitor the unit’s performance and identify any deviations from normal operation.

- Use diagnostic tools and techniques to pinpoint issues.

- Refer to manufacturer’s manuals and technical resources for guidance.

- Consult with experienced technicians or engineers as needed.

5. Describe the different types of pulling units and their applications.

There are various types of pulling units, each suited for specific applications:

- Mechanical pulling units: Use gears, chains, and pulleys to apply force.

- Hydraulic pulling units: Utilize hydraulic pressure to power the pulling mechanism.

- Electric pulling units: Operate on electricity and are often used in confined spaces.

- Pneumatic pulling units: Powered by compressed air and are suitable for hazardous environments.

- Tractor-mounted pulling units: Designed for use with tractors, providing increased mobility.

6. What are the key performance indicators used to evaluate the effectiveness of a pulling unit?

- Pulling force: The maximum force the unit can apply.

- Line speed: The rate at which the line is pulled.

- Efficiency: The ratio of useful work output to energy input.

- Reliability: The ability of the unit to operate without breakdowns or malfunctions.

- Maintainability: The ease with which the unit can be repaired and serviced.

7. How do you ensure the safety of personnel and equipment while operating a pulling unit?

- Follow all established safety protocols and procedures.

- Use appropriate personal protective equipment.

- Maintain a clean and organized work area.

- Inspect equipment regularly and ensure it is in good working order.

- Avoid working in hazardous conditions or with damaged equipment.

- Communicate clearly with colleagues and supervisors.

8. Describe your experience in operating and maintaining pulling units in different work environments.

Throughout my career, I have operated and maintained pulling units in various work environments, including:

- Construction sites: Installing and removing formwork, lifting heavy materials.

- Oil and gas industry: Pulling rods and tubing from wells.

- Mining operations: Moving equipment and materials.

- Shipyards: Loading and unloading vessels.

- Disaster relief operations: Removing debris and clearing pathways.

9. How do you handle unexpected situations or emergencies while operating a pulling unit?

In the event of an unexpected situation or emergency while operating a pulling unit, I prioritize the safety of personnel and equipment:

- Assess the situation and identify any immediate hazards.

- Communicate the emergency to relevant personnel and supervisors.

- Follow established emergency response procedures.

- Isolate the affected area and secure the pulling unit.

- Gather necessary resources and personnel to address the situation.

10. What are your career goals and how does this position align with them?

My career goal is to advance in the field of heavy machinery operation and maintenance. I believe that this position as a Pulling Unit Floorhand aligns well with my aspirations:

- Provides an opportunity to operate and maintain specialized pulling equipment.

- Offers hands-on experience in a demanding and dynamic work environment.

- Enhances my skills in troubleshooting, problem-solving, and safety.

- Creates a path for future growth and advancement within the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulling Unit Floorhand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulling Unit Floorhand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulling Unit Floorhands are responsible for a wide range of tasks on pulling units, ensuring the smooth and efficient operation of these machines. Their key responsibilities include:

1. Rigging Equipment

Floorhands are responsible for rigging equipment, including drawworks, engines, and pumps. They ensure that the equipment is properly secured and connected to provide the necessary power and functionality for the pulling unit.

- Assembling and disassembling drawworks, engines, and pumps.

- Connecting equipment to power sources and lines.

2. Maintaining Equipment

Floorhands perform regular maintenance on pulling units to ensure their optimal performance and prevent breakdowns. They conduct inspections, lubricate components, and make necessary repairs.

- Inspecting equipment for wear and tear.

- Lubricating moving parts.

- Making minor repairs and adjustments.

3. Operating Equipment

Floorhands operate pulling units to lift and move heavy loads. They control the drawworks, engines, and other equipment to precisely position loads and ensure safety.

- Positioning loads using drawworks.

- Controlling engines and pumps.

- Monitoring equipment for any issues.

4. Safety and Emergency Response

Floorhands are responsible for ensuring safety on pulling units. They follow established safety protocols, conduct risk assessments, and respond promptly to emergencies.

- Following safety procedures.

- Identifying hazards.

- Responding to accidents and emergencies.

Interview Tips

To ace the interview for a Pulling Unit Floorhand position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some tips to help candidates prepare:

1. Research the Company and Position

Before the interview, candidates should research the oil and gas industry, the company they’re applying to, and the specific role of a Pulling Unit Floorhand. Understanding the company’s operations and the requirements of the job will help candidates tailor their answers and present themselves as a suitable fit.

- Research the company’s website, industry news, and social media presence.

- Read job descriptions and identify key responsibilities and qualifications.

2. Practice Common Interview Questions

Candidates should anticipate and practice common interview questions. Preparing for these questions will boost their confidence and help them articulate their skills and experience effectively. Some common questions include:

- Tell me about your experience operating pulling units.

- Describe your approach to safety on the job.

- How do you handle working in high-pressure situations?

3. Highlight Relevant Skills and Experience

Candidates should emphasize their relevant skills and experience during the interview. They should articulate how their skills and experience align with the job requirements and demonstrate their ability to perform the duties effectively. For instance, they can highlight their experience in rigging equipment, maintaining machinery, or operating pulling units in challenging conditions.

- Provide specific examples of your work experience.

- Quantify your accomplishments with measurable results.

4. Be Prepared to Discuss Safety Protocols

Safety is paramount in the oil and gas industry. Candidates should be prepared to discuss their knowledge of safety protocols, risk assessments, and emergency response procedures. They should demonstrate their commitment to following safety regulations and their ability to prioritize safety in their work.

- Explain your understanding of safety procedures.

- Describe your experience conducting risk assessments.

Next Step:

Now that you’re armed with the knowledge of Pulling Unit Floorhand interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulling Unit Floorhand positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini