Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pulling Unit Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

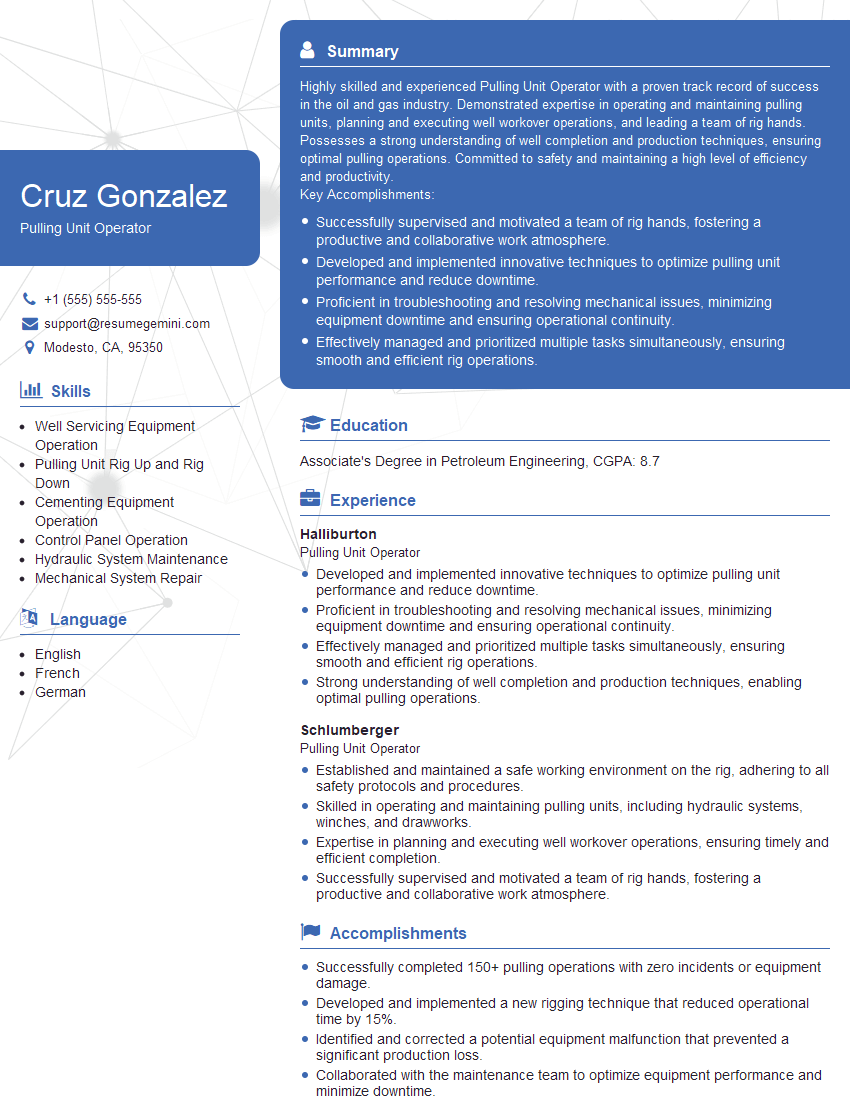

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulling Unit Operator

1. Explain the process of preparing a pulling unit for a workover operation?

The preparation of a pulling unit for a workover operation involves several steps to ensure a safe and efficient operation:

- Rigging the unit: Positioning the unit over the wellhead, leveling it, and securing it with appropriate stabilizers.

- Installing the BOPs (Blowout Preventers): Connecting and testing the BOPs to prevent uncontrolled fluid release.

- Stringing up the drill pipe: Loading and assembling the drill pipe into the derrick, making sure it is clean and properly inspected.

- Attaching the traveling block: Connecting the traveling block to the top of the drill pipe, which will support the weight of the string.

- Running the kelly: Installing the kelly, a short section of pipe used to rotate the drill string, into the swivel.

2. Describe the safety precautions that must be taken when operating a pulling unit?

Operating a pulling unit requires strict adherence to safety protocols to prevent accidents and injuries:

Safe Work Practices:

- Wearing appropriate PPE (Personal Protective Equipment) including hard hat, gloves, and protective clothing.

- Following lockout/tagout procedures to isolate energy sources during maintenance or repairs.

- Maintaining a clean and organized work area to prevent tripping hazards.

Mechanical Safety:

- Inspecting equipment regularly for any damage or wear and ensuring proper maintenance.

- Using slings, chains, and other lifting devices properly to prevent load drops.

- Ensuring that all guards and safety devices are in place and functioning correctly.

3. How do you troubleshoot common problems that may occur while operating a pulling unit?

Troubleshooting common problems encountered during pulling unit operations requires a combination of knowledge and experience:

- Engine not starting: Checking fuel levels, battery connections, and if necessary, performing engine diagnostics.

- Hydraulic system leaks: Inspecting hoses, fittings, and cylinders for damage or loose connections, and replacing or tightening as needed.

- Drill pipe stuck: Assessing the situation, trying to free the pipe using jarring techniques, and if unsuccessful, considering pulling out of the hole.

- Overpull: Reacting quickly to reduce the load and prevent damage to the equipment or injury to personnel.

4. How do you calculate the tension on the drill string and what factors affect it?

Calculating the tension on the drill string is crucial for safe and efficient operations:

- Determining weight of the drill string: Multiplying the weight per foot of each component by its length.

- Calculating hook load: Measuring the weight of the suspended components, including the drill string, traveling block, and any additional tools.

- Factors affecting tension: Friction, drag, and formation resistance influence the tension on the drill string.

5. Describe the different types of pulling units and their applications?

Pulling units vary in design and applications, each suited for specific requirements:

- Truck-mounted pulling units: Mobile and versatile units commonly used for shallow wells and quick operations.

- Skid-mounted pulling units: Larger and more powerful units designed for deeper wells and heavier loads.

- Electric pulling units: Environmentally friendly and energy-efficient units suitable for indoor or enclosed spaces.

6. How do you maintain and service a pulling unit to ensure optimal performance and longevity?

Regular maintenance and servicing are vital to maintain the pulling unit’s performance and safety:

- Daily inspections: Checking fluid levels, monitoring gauges, and identifying any potential issues.

- Periodic maintenance: Lubricating components, changing filters, and performing scheduled inspections.

- Repairs: Promptly addressing any mechanical failures or damage to prevent further problems.

7. Describe the process of pulling and running tubing using a pulling unit?

Pulling and running tubing with a pulling unit involves careful execution:

- Pulling tubing: Disconnecting and removing the tubing string from the well.

- Running tubing: Installing new or repaired tubing into the well, ensuring proper connections and alignment.

8. How do you handle emergencies such as blowouts or stuck pipe while operating a pulling unit?

Responding to emergencies during pulling unit operations requires a combination of preparedness and quick decision-making:

Blowouts:

- Shutting in the well and activating the BOP system.

- Evacuating the area and contacting emergency services.

Stuck pipe:

- Assessing the situation and attempting to free the pipe using jarring techniques.

- If unsuccessful, considering cutting the pipe and retrieving it in sections.

9. What is the role of a Pulling Unit Operator in maintaining a safe and efficient work environment?

As a Pulling Unit Operator, safety and efficiency are paramount responsibilities:

- Adhering to all safety protocols and guidelines.

- Inspecting equipment regularly and reporting any issues promptly.

- Ensuring proper maintenance and servicing of the unit.

- Communicating effectively with colleagues and supervisors.

10. How do you stay updated on the latest industry best practices and advancements in pulling unit operations?

Continuously improving knowledge and skills is essential in this field:

- Attending industry conferences and seminars.

- Reading technical publications and trade journals.

- Consulting with experienced professionals and experts.

- Participating in online forums and discussions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulling Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulling Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulling Unit Operators play a crucial role in the oil and gas industry by operating and maintaining pulling units used to extract oil and gas from wells. Their responsibilities encompass various aspects of well servicing and maintenance.

1. Pulling and Running Equipment

Operate pulling units to retrieve or insert downhole equipment such as rods, tubing, and pumps from wells.

- Calculate and adjust tension on the pulling line to ensure safe and efficient operation.

- Monitor equipment condition and identify potential issues during pulling and running operations.

2. Equipment Maintenance and Repair

Perform routine maintenance and repairs on pulling units and associated equipment to ensure optimal performance.

- Inspect, clean, and lubricate equipment components as per established procedures.

- Troubleshoot and resolve mechanical and electrical issues promptly to minimize downtime.

3. Safety and Compliance

Adhere to strict safety regulations and industry standards to prevent accidents and protect personnel.

- Conduct pre-operational safety checks and obtain necessary permits before starting operations.

- Monitor weather conditions and take appropriate precautions to ensure safety during adverse conditions.

4. Communication and Coordination

Maintain effective communication with other crew members, supervisors, and clients to coordinate operations.

- Provide timely updates on job progress and potential issues to relevant stakeholders.

- Coordinate with other teams to ensure smooth execution of well servicing activities.

Interview Tips

To ace the interview for a Pulling Unit Operator position, it is essential to demonstrate a strong understanding of the industry, technical expertise, and a commitment to safety. Here are a few tips to help you prepare:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, safety record, and industry trends. This will enable you to engage in meaningful conversations and demonstrate your knowledge of the field.

- Visit the company’s website and social media pages to gather information about their culture, values, and recent projects.

- Read industry publications and attend webinars to stay updated on the latest technologies and best practices.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating pulling units, performing maintenance, and ensuring safety. Quantify your accomplishments and provide specific examples to showcase your abilities.

- Discuss your role in successful pulling and running operations, highlighting any challenges you faced and how you overcame them.

- Present your experience in troubleshooting and repairing equipment, demonstrating your technical proficiency and problem-solving skills.

3. Demonstrate Safety Consciousness

Safety is paramount in the oil and gas industry. Convey your strong commitment to safety by describing your adherence to regulations, proactive risk identification, and emergency response procedures.

- Explain your experience in conducting safety inspections and hazard assessments, ensuring that all operations meet safety standards.

- Discuss your participation in safety training programs and your understanding of industry best practices.

4. Prepare for Technical Questions

Expect to answer technical questions related to pulling unit operations, equipment maintenance, and safety protocols. Review common industry terminology and concepts to demonstrate your knowledge.

- Study the principles of pulling unit operations, including tension calculations, equipment handling, and downhole tools.

- Familiarize yourself with different types of pulling units, their components, and maintenance procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pulling Unit Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!