Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pulp and Paper Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

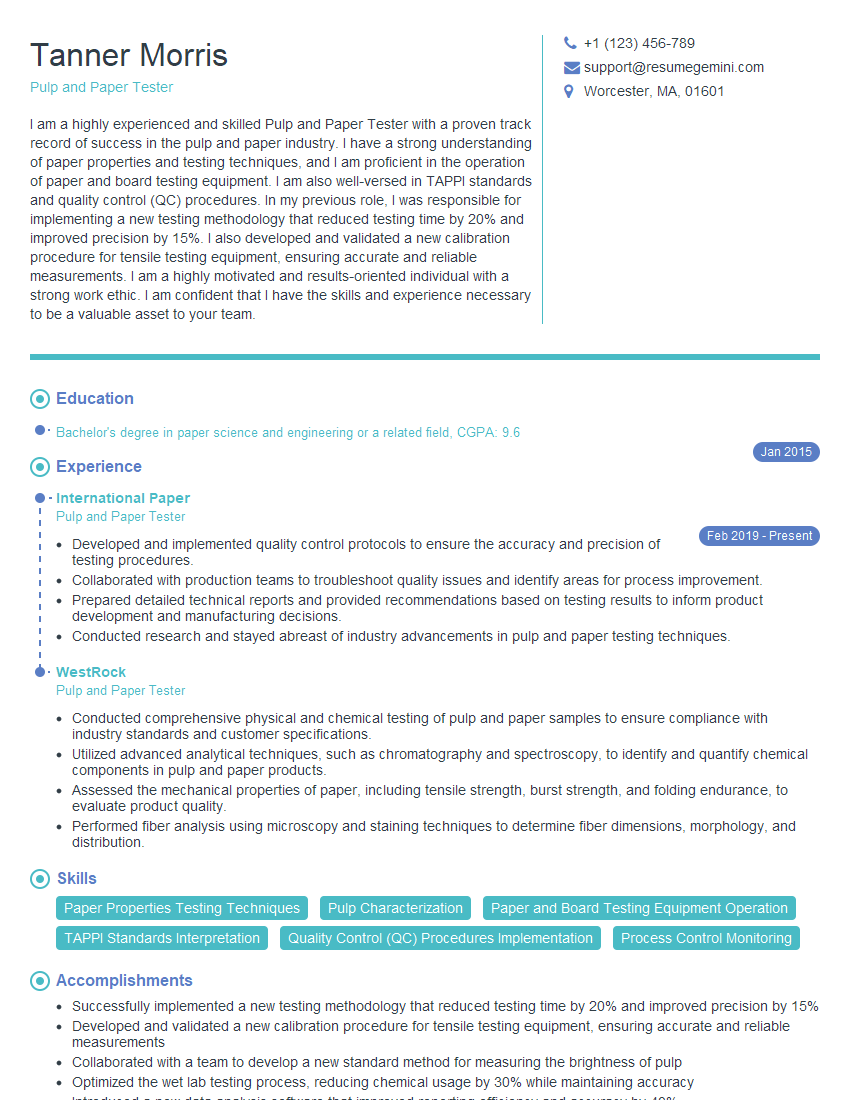

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp and Paper Tester

1. What are the key physical properties of paper that you test for?

Answer: As a Pulp and Paper Tester, I am responsible for evaluating the physical properties of paper to ensure they meet specific standards. Some of the key physical properties I test for include:

- Tensile strength

- Tear strength

- Bursting strength

- Folding endurance

- Opacity and brightness

2. How do you determine the tensile strength of paper?

Answer: Determining the tensile strength of paper involves the following steps:

- Preparing the specimen according to the relevant standard

- Clamping the specimen in the tensile testing machine

- Applying tension to the specimen at a constant rate of extension

- Recording the force required to break the specimen

- Calculating the tensile strength by dividing the breaking force by the original cross-sectional area of the specimen

3. What methods are commonly used to test for the porosity of paper?

Answer: There are several methods commonly used to test for the porosity of paper, including:

- Gurley method

- Bendtsen method

- Parker Print Surf method

- Sheffield method

4. How do you calibrate the equipment used in your testing procedures?

Answer: Calibration is crucial to ensuring the accuracy and reliability of my testing results. I follow a rigorous calibration schedule for all equipment used in my testing procedures:

- Using standard reference materials

- Following manufacturer’s guidelines and industry best practices

- Documenting and maintaining calibration records

5. What is the difference between wet tensile strength and dry tensile strength?

Answer: Wet tensile strength refers to the tensile strength of paper when it is wet or saturated with water. Dry tensile strength, on the other hand, refers to the tensile strength of paper in its dry state. Wet tensile strength is generally lower than dry tensile strength due to the weakening of the paper’s fibers when they are wet.

6. What are the most common defects or non-conformities you encounter in paper samples?

Answer: During my testing procedures, I encounter various defects or non-conformities in paper samples, including:

- Low tensile strength

- High porosity

- Uneven surface

- Paper breaks

- Non-uniformity in thickness

7. How do you ensure the repeatability and accuracy of your test results?

Answer: Ensuring the repeatability and accuracy of my test results is of utmost importance. To achieve this, I adhere to the following practices:

- Following standardized testing methods

- Using calibrated equipment

- Maintaining a controlled testing environment

- Performing multiple tests on each sample

- Documenting all test results

8. How do you analyze and interpret test data?

Answer: After conducting the necessary tests, I analyze and interpret the results to assess the quality of the paper samples. I:

- Compare the test results to established standards and specifications

- Identify any deviations or non-conformities

- Provide recommendations for corrective actions if necessary

- Generate test reports and maintain records of all findings

9. How do you stay up-to-date with the latest developments in the paper industry?

Answer: The paper industry is constantly evolving, and it is essential for me to stay abreast of the latest developments. To do this, I:

- Attend industry conferences and seminars

- Read trade publications and technical journals

- Participate in online forums and LinkedIn groups

- Network with other professionals in the field

10. How would you approach testing a new type of paper that has unique properties?

Answer: When encountering a new type of paper with unique properties, I would approach its testing as follows:

- Thoroughly review the manufacturer’s specifications and technical data

- Identify any special testing requirements or considerations

- Select the appropriate testing methods and equipment

- Conduct preliminary tests to determine the material’s basic properties

- Refine the testing parameters and procedures as needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp and Paper Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp and Paper Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp and Paper Testers are responsible for ensuring the quality of paper and pulp products. They perform a variety of tests to measure physical and chemical properties, and report their findings to management. Key job responsibilities include:

1. Sampling and Testing

Pulp and Paper Testers collect samples of paper and pulp from the production process, and conduct a variety of tests to measure their properties. These tests may include:

- Brightness tests

- Color tests

- Tensile strength tests

- Burst strength tests

- Tear strength tests

2. Data Collection and Analysis

Pulp and Paper Testers record the results of their tests and analyze the data to identify trends and patterns. They may also use statistical software to create graphs and charts that illustrate their findings.

3. Reporting

Pulp and Paper Testers prepare reports that summarize their findings and make recommendations for improvements. These reports are used by management to make decisions about the production process.

4. Quality Control

Pulp and Paper Testers work with other members of the production team to ensure that the quality of paper and pulp products meets customer specifications. They may also participate in quality control programs to improve the production process.

Interview Tips

Preparing for an interview for a Pulp and Paper Tester position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace the interview:

1. Research

Before the interview, research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, as well as the key requirements of the job. You should also review your resume and be prepared to discuss your experience and qualifications.

2. Practice

Once you have a good understanding of the company and the position, you should practice answering common interview questions. This will help you to feel more confident and prepared during the interview. You should also practice your presentation skills, as you may be asked to give a brief presentation during the interview.

3. Be Professional

It is important to dress professionally and arrive on time for the interview. You should also be polite and respectful to everyone you meet, including the receptionist and other employees. Your professionalism will make a good impression on the interviewer.

4. Be Enthusiastic

Pulp and Paper Testers are passionate about their work. They are enthusiastic about the paper and pulp industry, and they are eager to learn and grow. During the interview, convey your enthusiasm for the position and for the company. This will show the interviewer that you are genuinely interested in the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pulp and Paper Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pulp and Paper Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.