Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pulp Beater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

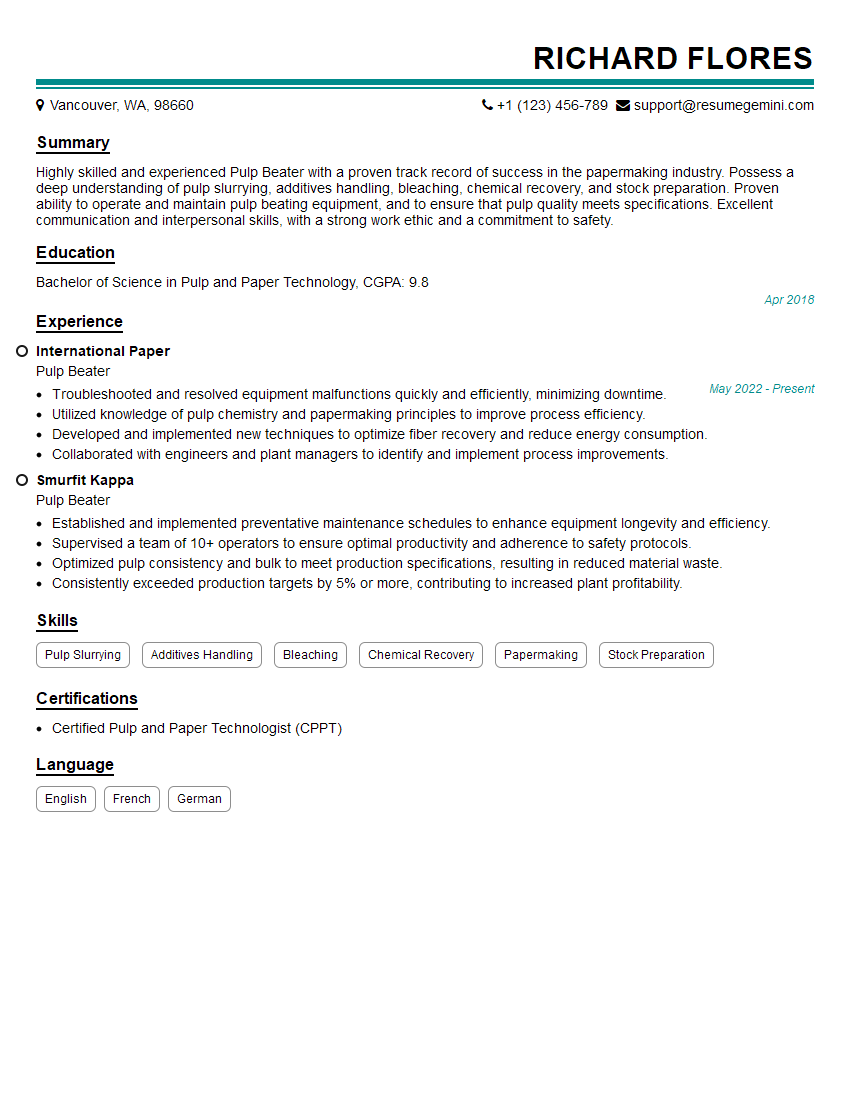

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Beater

1. Explain the process of pulp beating and its different stages.

Pulp beating is a mechanical process that modifies the physical properties of pulp fibers by applying mechanical energy. It involves repeatedly hitting the fibers with blunt blades or bars to break down and separate the fibers. The process is carried out in different stages, each with a specific goal:

- Defibering: The initial stage breaks down large fiber bundles into individual fibers, increasing the specific surface area available for bonding.

- Hydration: This stage promotes the penetration of water into the fibers, allowing for better fiber swelling and flexibility.

- Fibrillation: The fibers are further broken down, creating fine fibrils that increase the fiber surface area and bonding potential.

- Cutting: The fibers are cut into shorter lengths to reduce fiber strength and improve flexibility.

2. Describe the factors that affect the efficiency of pulp beating.

Pulp Properties:

- Fiber type (hardwood vs. softwood)

- Fiber length

- Fiber strength

- Pulp consistency

Beating Equipment:

- Type of beater (Hollander beater, conical refiner)

- Beater roll speed and clearance

- Blade or bar design

Process Parameters:

- Beating time

- Temperature

- Chemical additives

3. What are the key properties of beaten pulp that are important for papermaking?

- Fiber length distribution: Beating reduces fiber length, which affects paper strength and porosity.

- Fibrillation: Increased fibrillation enhances fiber bonding and improves paper smoothness and opacity.

- Water retention: Beaten pulp has higher water retention due to increased fiber surface area, which aids in sheet formation and bonding.

- Tensile strength: Beating can increase or decrease tensile strength depending on the extent of fiber cutting and fibrillation.

- Tear strength: Beating typically reduces tear strength as fibers become shorter and weaker.

4. How do you optimize the beating process for a specific paper grade?

- Determine the desired pulp properties for the target paper grade.

- Select the appropriate beating equipment and settings.

- Conduct pilot-scale trials to establish optimal beating conditions (time, speed, clearance).

- Monitor and adjust the beating process based on pulp quality testing.

- Make adjustments to the beating parameters as needed to achieve the desired pulp properties.

5. Explain the role of chemical additives in the pulp beating process.

- Retention aids: Improve fiber-to-fiber bonding and reduce water retention.

- Wetting agents: Enhance fiber hydration and fibrillation.

- Dispersants: Prevent fiber agglomeration and promote uniform beating.

- Modifiers: Adjust pulp pH and modify fiber surface properties to enhance bonding.

- Bleach: Can be added during beating to achieve desired brightness levels in the final paper.

6. How do you maintain the quality of beaten pulp in a production environment?

- Establish and adhere to standard operating procedures.

- Regularly calibrate and maintain beating equipment.

- Conduct frequent pulp quality testing to monitor key parameters.

- Implement a feedback loop to adjust beating conditions based on test results.

- Train and supervise operators on proper beating techniques.

7. What are the potential troubleshooting issues that can arise during the pulp beating process and how do you address them?

- Poor fiber disintegration: Adjust beater settings, inspect equipment for damage.

- Excessive fiber cutting: Reduce beating time or speed.

- Fiber agglomeration: Add dispersants, adjust pH.

- Non-uniform beating: Calibrate beater equipment, check for bearing issues.

- Pulp contamination: Inspect equipment for leaks or damage, implement preventive maintenance measures.

8. What are the latest advancements in pulp beating technology?

- Energy-efficient beaters: Utilize advanced beater designs and process optimizations to reduce energy consumption.

- Inline beating: Integrates beating into the papermaking process, offering improved fiber control and consistency.

- Fiber characterization techniques: Laser-based analyzers and other methods provide real-time monitoring of fiber properties during beating.

- Process control systems: Utilize data analytics and automation to optimize beating parameters and maintain consistent pulp quality.

9. Describe the environmental considerations associated with the pulp beating process.

- Water usage: Optimize water consumption and implement water recycling systems.

- Wastewater discharge: Treat wastewater to meet environmental regulations.

- Chemical additives: Use environmentally friendly alternatives and minimize additive usage.

- Energy consumption: Utilize energy-efficient equipment and explore renewable energy sources.

10. How do you keep up-to-date with the latest developments in pulp beating technology and best practices?

- Attend industry conferences and exhibitions.

- Read technical journals and research papers.

- Network with other professionals in the field.

- Participate in continuing education programs.

- Stay informed about new products and technologies from equipment manufacturers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Beater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Beater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp Beaters are responsible for the beating process of paper pulp, which is a crucial step in paper production. Their key responsibilities include:1. Pulp Beating and Refinement

Pulp Beaters operate and monitor beaters and refiners to reduce the pulp consistency to desired levels.

- Operate beaters and refiners to break down fibers and prepare pulp for further processing.

- Adjust machine settings, such as beater roll speed and pressure, to achieve the desired pulp quality.

2. Process Monitoring and Control

Ensure that the beating process meets quality standards and production targets.

- Monitor process parameters, including pulp consistency, temperature, and pH levels, to maintain optimum beating conditions.

- Conduct regular tests on pulp samples to ensure compliance with quality specifications.

3. Equipment Maintenance and Troubleshooting

Maintain beater equipment and troubleshoot any issues that may arise during the beating process.

- Perform routine maintenance tasks, such as cleaning, lubricating, and inspecting beater equipment.

- Identify and rectify any malfunctions or breakdowns in the beating system.

4. Safety and Compliance

Adhere to workplace safety regulations and ensure compliance with environmental standards.

- Follow established safety protocols and wear appropriate protective gear.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

To ace your interview for a pulp beater position, it’s essential to prepare thoroughly and showcase your relevant skills and experience. Here are some tips and hacks to help you succeed:

1. Research the Company and Role

Familiarize yourself with the company’s background, operations, and the specific requirements of the pulp beater role. This will enable you to tailor your answers and demonstrate your understanding of the position.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends and technologies.

2. Highlight Your Technical Expertise

Emphasize your knowledge of pulp beating processes, equipment, and quality control procedures. Quantify your experience and provide specific examples of your contributions.

- Describe your experience in operating and maintaining beaters and refiners.

- Share examples of how you have optimized the beating process to improve pulp quality.

3. Showcase Your Problem-Solving Abilities

Interviewers will be interested in your ability to troubleshoot and resolve issues that may arise during the beating process. Highlight your critical thinking skills and provide examples of how you have handled challenges in the past.

- Describe a situation where you identified and resolved a problem with a beater.

- Explain how you used your knowledge and experience to find an effective solution.

4. Emphasize Teamwork and Safety

Pulp beating often involves working as part of a team. Share examples of your collaborative experiences and highlight your commitment to safety and compliance.

- Describe your experience working with others to achieve common goals.

- Explain how you ensure safety in your work environment and comply with relevant regulations.

5. Practice Your Answers

Consider common interview questions and practice your answers to build confidence and articulate your skills effectively. You can practice with a friend, family member, or career counselor.

- Prepare answers to questions about your experience, skills, and why you are interested in the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

6. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview and arrive on time to demonstrate your professionalism and respect for the interviewer’s time.

- Choose business casual attire or a suit.

- Be punctual and arrive a few minutes early to show that you value the interview.

Next Step:

Now that you’re armed with the knowledge of Pulp Beater interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulp Beater positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini