Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pulp Cooker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

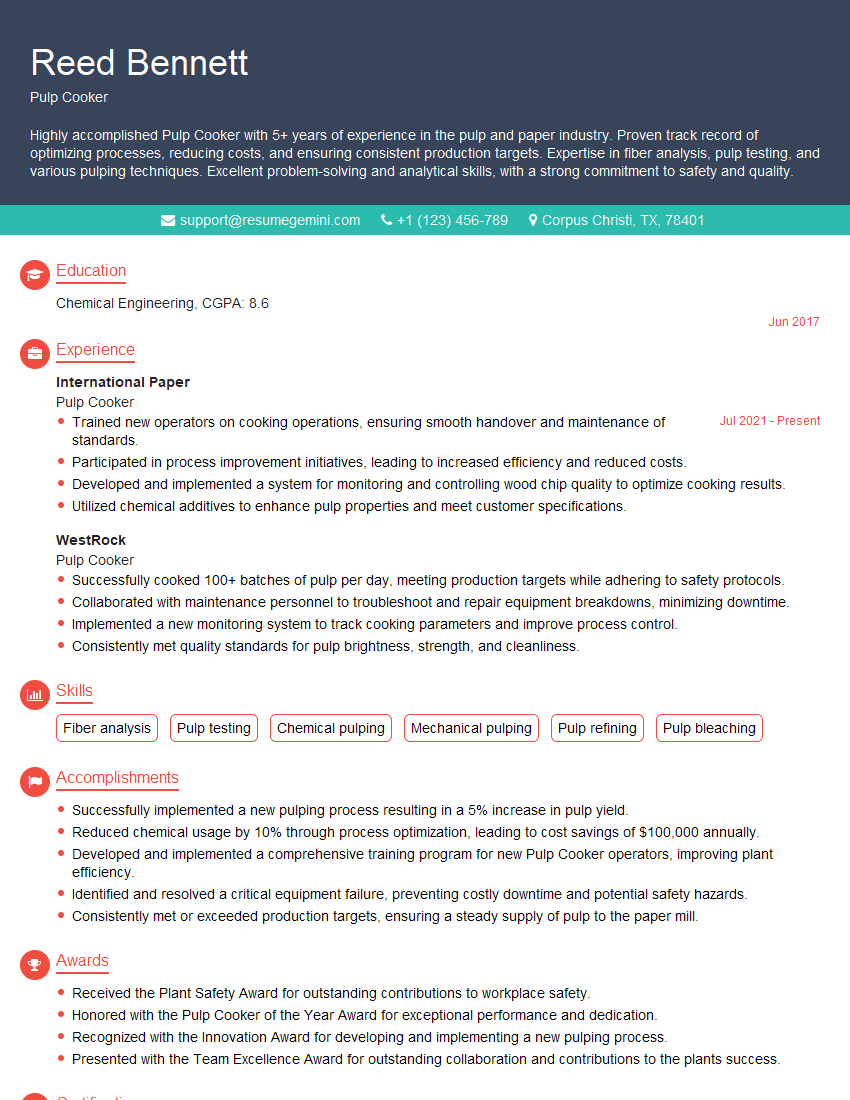

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Cooker

1. What are the key components of a pulp cooker, and how do they contribute to the pulping process?

The key components of a pulp cooker are:

- Cooking vessel: This is where the wood chips and cooking chemicals are mixed and heated.

- Impregnation zone: This is where the wood chips are saturated with cooking liquor.

- Cooking zone: This is where the wood chips are cooked under pressure and temperature.

- Blow tank: This is where the cooked pulp is discharged from the cooker.

These components work together to convert wood chips into pulp by breaking down the lignin and hemicellulose in the wood.

2. What are the different types of pulp cookers, and what are their advantages and disadvantages?

Batch cookers

- Advantages: Simple design, easy to operate, suitable for a variety of raw materials.

- Disadvantages: Long cooking times, high energy consumption, difficult to control cooking conditions.

Continuous cookers

- Advantages: Shorter cooking times, lower energy consumption, better control of cooking conditions.

- Disadvantages: More complex design, more difficult to operate, not suitable for all raw materials.

3. What are the key process parameters in pulp cooking, and how do they affect the quality of the pulp?

- Temperature: Higher temperatures result in faster cooking times, but can also lead to pulp degradation.

- Pressure: Higher pressures result in higher pulp yields, but can also lead to pulp swelling and strength loss.

- Cooking time: Longer cooking times result in higher pulp yields, but can also lead to pulp degradation.

- Cooking liquor composition: The composition of the cooking liquor affects the rate of delignification and hemicellulose removal.

4. What are the common problems that can occur during pulp cooking, and how can they be prevented or resolved?

- Overcooking: This can result in pulp that is weak and has low brightness.

- Undercooking: This can result in pulp that is not fully delignified and has high rejects.

- Foaming: This can occur when there is too much air in the cooking liquor.

- Corrosion: This can occur when the cooking liquor is too acidic.

These problems can be prevented or resolved by:

- Controlling the process parameters.

- Using the proper cooking liquor composition.

- Maintaining the equipment in good condition.

5. What are the safety precautions that must be taken when operating a pulp cooker?

- Wear proper personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and earplugs.

- Be aware of the hazards of the cooking liquor, including its corrosive and flammable properties.

- Do not enter the cooking vessel until it has been properly depressurized and cooled.

- Follow all operating procedures and safety protocols.

6. What are the recent advances in pulp cooking technology, and how are they improving the pulp quality and process efficiency?

- New cooking methods: These methods, such as oxygen delignification and biopulping, are more efficient and environmentally friendly than traditional methods.

- Improved process control: Advanced sensors and control systems are being used to improve the control of the cooking process and optimize pulp quality.

- New materials: New materials, such as corrosion-resistant alloys, are being used to improve the durability and safety of pulp cookers.

7. How do you stay up-to-date on the latest advancements in pulp cooking technology?

- Attend industry conferences and workshops.

- Read trade publications and journals.

- Network with other pulp and paper professionals.

8. What are your strengths and weaknesses as a Pulp Cooker?

My strengths include my:

- In-depth knowledge of pulp cooking technology and processes.

- Strong understanding of the chemistry of pulp cooking.

- Proven ability to operate and maintain pulp cookers safely and efficiently.

- Excellent troubleshooting skills.

- Strong communication and interpersonal skills.

My weaknesses include my:

- Limited experience with some of the newer pulp cooking technologies.

- I am still learning about the pulp and paper industry.

9. Why are you interested in working as a Pulp Cooker for our company?

I am interested in working as a Pulp Cooker for your company because:

- I am passionate about the pulp and paper industry and believe that I can make a valuable contribution to your company.

- I am eager to learn new things and am confident that I can quickly become a valuable asset to your team.

- I am a hard worker and am always willing to go the extra mile.

10. Do you have any questions for me?

I do have a few questions:

- What are the biggest challenges facing the pulp and paper industry today?

- What are your company’s plans for the future?

- What are the opportunities for advancement within the company?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Cooker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Cooker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pulp Cooker is a crucial member of the production team, responsible for operating and maintaining the pulp digesters to produce quality pulp for paper manufacturing.

1. Pulp Production

The core responsibility of a Pulp Cooker involves operating and monitoring digesters to cook wood chips or other raw materials.

- Ensure accurate chemical and temperature control throughout the cooking process.

- Manage cooking time and chemical additions to achieve optimal pulp quality.

2. Equipment Maintenance and Monitoring

Pulp Cookers are responsible for maintaining the equipment used in the cooking process.

- Perform routine inspections, maintenance, and repairs of digesters, pumps, and other equipment.

- Monitor equipment performance and identify potential issues for timely corrective action.

3. Process Optimization and Troubleshooting

The Pulp Cooker plays a vital role in optimizing the cooking process and troubleshooting any issues.

- Analyze pulp quality data and make adjustments to improve efficiency and product quality.

- Troubleshoot and resolve process problems related to cooking conditions, chemical composition, and equipment malfunctions.

4. Safety and Environmental Compliance

Pulp Cookers have a responsibility to ensure safety and environmental compliance in the workplace.

- Adhere to all safety regulations and protocols related to the operation of digesters and chemical handling.

- Monitor environmental parameters to minimize the impact of the cooking process on the environment.

Interview Tips

Preparing for a Pulp Cooker interview requires thorough research and understanding of the role. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Gain insights into the company’s history, operations, and market position. Understand the pulp and paper industry trends and challenges.

2. Practice Common Interview Questions

Prepare for questions related to your pulp cooking experience, knowledge of equipment, process optimization techniques, and safety procedures.

3. Showcase Your Problem-Solving Skills

Highlight your ability to identify and resolve process issues, ensuring pulp quality and production efficiency.

4. Emphasize Your Safety Consciousness

Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment.

5. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your engagement and interest in the role. Prepare questions about the company’s sustainability initiatives, production goals, or career growth opportunities.

Next Step:

Now that you’re armed with the knowledge of Pulp Cooker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulp Cooker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini