Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pulp Drier Firer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pulp Drier Firer so you can tailor your answers to impress potential employers.

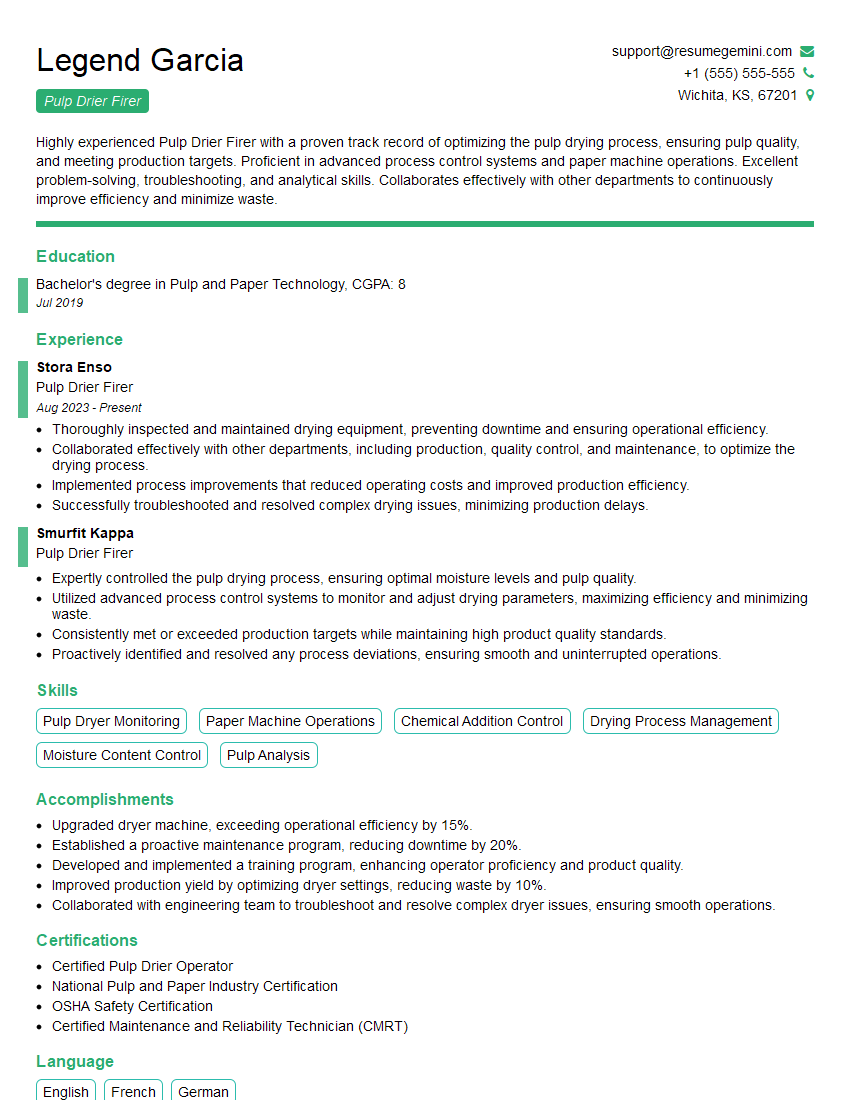

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Drier Firer

1. What are the key responsibilities of a Pulp Drier Firer?

- Operate and monitor the pulp drying machine to produce high-quality pulp sheets.

- Adjust machine settings, such as temperature, speed, and tension, to optimize production.

- Monitor and maintain equipment, including the dryer, conveyor, and press, to ensure smooth operation.

- Troubleshoot and resolve machine issues promptly to minimize downtime.

- Maintain a clean and safe work environment in accordance with safety regulations.

2. Describe the process of operating a pulp drying machine.

Pre-Installation Process

- Inspect the equipment to ensure it is in good working order.

- Install the pulp sheets onto the machine.

During Operation

- Monitor the machine’s temperature, speed, and tension to ensure optimal performance.

- Adjust settings as needed to maintain desired pulp quality.

- Observe the drying process to detect any abnormalities or defects.

Post-Installation Process

- Remove the dried pulp sheets from the machine.

- Clean and maintain the machine as per the manufacturer’s guidelines.

3. How do you ensure the quality of the pulp sheets produced by the drying machine?

- Monitor the pulp sheets throughout the drying process to ensure they meet specifications.

- Calibrate and maintain the machine regularly to ensure accurate settings and readings.

- Perform quality control tests on the finished pulp sheets to verify their properties, such as moisture content and strength.

- Implement preventive maintenance procedures to minimize machine downtime and ensure consistent production quality.

4. What are the potential hazards associated with operating a pulp drying machine and how do you mitigate them?

- Fire: Use proper safety equipment, maintain a clean work area, and adhere to fire safety protocols.

- Explosions: Ensure proper ventilation and follow procedures for handling flammable materials.

- Chemical exposure: Wear appropriate personal protective equipment and handle chemicals according to safety data sheets.

- Mechanical hazards: Keep work area clear, wear protective clothing, and follow lockout/tagout procedures.

- Slips and falls: Maintain a clean and dry work environment, and wear non-slip footwear.

5. Describe your experience in troubleshooting and resolving issues with pulp drying machines.

- Identify the problem by observing the machine’s operation and data.

- Refer to technical manuals and consult with colleagues or supervisors for guidance.

- Perform necessary adjustments or repairs to resolve the issue.

- Test the machine to ensure it is functioning properly and meets specifications.

6. How do you prioritize tasks and manage your time effectively in a busy work environment?

- Assess the urgency and importance of tasks.

- Create a work schedule and stick to it as much as possible.

- Delegate tasks to others when appropriate.

- Take breaks to stay focused and avoid burnout.

- Communicate effectively with colleagues and supervisors to coordinate tasks and avoid overlaps.

7. Describe a situation where you had to work independently to solve a problem with the pulp drying machine.

- Identified a problem with the machine’s temperature control system.

- Consulted the technical manual and performed diagnostic tests.

- Replaced a faulty sensor and recalibrated the system.

- Tested the machine and verified that the problem was resolved.

8. How do you stay up-to-date with the latest developments and best practices in pulp drying technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Network with other professionals in the field.

- Seek training and development opportunities.

9. What are your career goals and how do you see this role contributing to your professional development?

- Aspire to become a lead pulp drier firer or supervisor.

- This role will provide hands-on experience and technical knowledge to advance my career.

- Opportunity to contribute to the company’s production goals and quality standards.

10. Why are you interested in working for our company specifically?

- Impressed by the company’s reputation for innovation and quality.

- Excited about the opportunity to work on state-of-the-art pulp drying equipment.

- Believe that my skills and experience would be a valuable asset to the team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Drier Firer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Drier Firer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp Drier Firers are responsible for operating and maintaining pulp drying machinery to ensure the production of high-quality pulp.

1. Pulp Drying Operation

Monitor and adjust drying conditions, such as temperature, humidity, and airflow, to optimize pulp drying efficiency.

- Control the speed of the conveyor belt to regulate the residence time of pulp in the dryer.

- Inspect pulp sheets for defects and take corrective actions to maintain quality.

2. Machinery Maintenance

Perform routine maintenance on pulp drying equipment, including cleaning, lubrication, and minor repairs.

- Follow established maintenance schedules and procedures to ensure equipment reliability.

- Identify potential problems and take proactive measures to prevent breakdowns.

3. Process Monitoring

Monitor process parameters, such as temperature, pressure, and moisture content, to ensure optimal drying conditions.

- Analyze data and make adjustments as needed to maintain process efficiency and product quality.

- Troubleshoot process deviations and implement corrective actions to minimize production disruptions.

4. Safety and Compliance

Follow established safety procedures and wear appropriate personal protective equipment.

- Maintain a clean and organized work area to prevent accidents and ensure compliance with industry regulations.

- Report any unsafe conditions or equipment malfunctions to supervisors.

Interview Tips

Preparing thoroughly for an interview can increase your chances of success. Here are some tips for candidates aspiring to land the job of a Pulp Drier Firer:

1. Research the Company and Job Role

Gather information about the company’s history, culture, products or services, and the specific requirements of the Pulp Drier Firer position. This will help you tailor your answers and demonstrate your understanding of the role.

- Visit the company’s website, read industry news, and connect with current or former employees on LinkedIn.

- Carefully review the job description and highlight your skills and experience that align with the required qualifications.

2. Practice Your Answers

Anticipate common interview questions related to your technical skills, experience, and problem-solving abilities. Prepare thoughtful and concise answers that showcase your knowledge and competence.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice your answers aloud to improve your delivery and ensure clarity.

3. Emphasize Safety and Attention to Detail

Pulp Drier Firers play a crucial role in ensuring safety and maintaining high product quality. Highlight your commitment to following safety protocols and your ability to pay close attention to details.

- Describe instances where you identified and resolved potential safety hazards or quality issues.

- Explain your understanding of industry regulations and best practices related to pulp drying operations.

4. Showcase Your Troubleshooting Skills

Pulp drying processes can encounter unexpected challenges. Demonstrate your ability to troubleshoot problems, identify root causes, and implement effective solutions.

- Share examples of troubleshooting scenarios you have successfully handled in previous roles.

- Explain your analytical approach and how you evaluate data to determine the best course of action.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pulp Drier Firer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.