Feeling lost in a sea of interview questions? Landed that dream interview for Pulp Grinder and Blender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pulp Grinder and Blender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

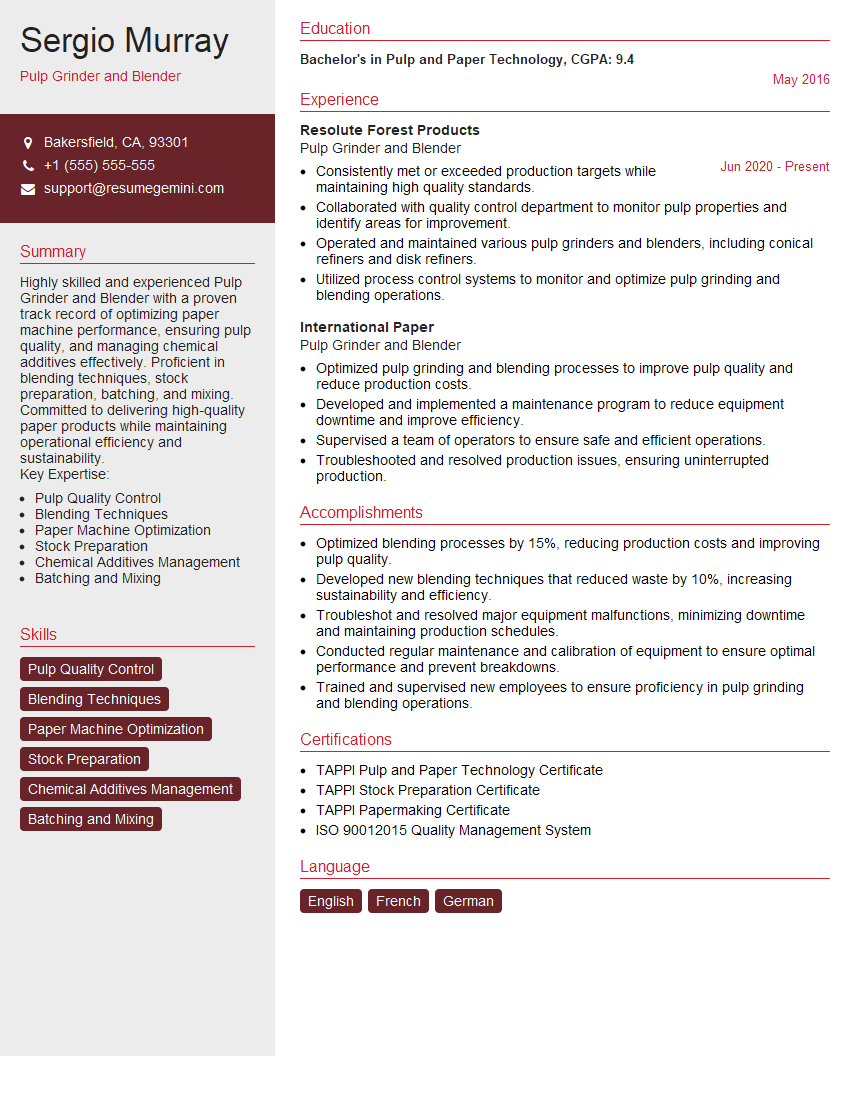

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Grinder and Blender

1. Describe the primary responsibilities of a Pulp Grinder and Blender?

As a Pulp Grinder and Blender, my responsibilities would typically include:

- Operating and maintaining pulp grinders and blenders to produce paper pulp

- Controlling the consistency and quality of the pulp

- Monitoring and adjusting grinding and blending processes to meet specifications

- Performing regular maintenance and repairs on equipment

- Ensuring compliance with safety regulations and environmental standards

2. Explain the different types of pulp grinders and their applications?

Mechanical Grinders

- Use mechanical force to grind wood chips into pulp

- Produce high-yield pulp with low strength properties

- Used for making newsprint, cardboard, and other low-grade papers

Chemical Grinders

- Use chemicals to soften wood chips before grinding

- Produce high-quality pulp with high strength properties

- Used for making fine papers, writing papers, and specialty papers

Refiners

- Used to further refine pulp to improve its properties

- Can be used to increase pulp strength, brightness, and smoothness

3. What factors affect the quality of the pulp produced?

The quality of the pulp produced is affected by several factors, including:

- Type of wood used

- Grinding process and equipment

- Chemical additives used

- Consistency and temperature of the pulp

- Presence of impurities

4. How do you ensure the consistency of the pulp produced?

To ensure the consistency of the pulp produced, I would:

- Monitor the grinding and blending processes closely

- Regularly sample and test the pulp

- Make adjustments to the processes as needed to meet specifications

- Use quality control techniques to identify and correct any deviations

5. Describe the safety precautions that must be taken when operating pulp grinders and blenders?

When operating pulp grinders and blenders, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs

- Follow lockout/tagout procedures when performing maintenance

- Be aware of the potential for moving machinery and rotating blades

- Never operate equipment alone

- Report any unsafe conditions or equipment malfunctions immediately

6. How do you maintain and troubleshoot pulp grinders and blenders?

To maintain and troubleshoot pulp grinders and blenders, I would:

- Perform regular inspections and maintenance tasks

- Identify and replace worn or damaged parts

- Calibrate and adjust equipment as needed

- Troubleshoot and resolve equipment malfunctions

- Maintain accurate maintenance records

7. What are the environmental regulations that apply to pulp grinding and blending operations?

The environmental regulations that apply to pulp grinding and blending operations include:

- Clean Water Act

- Clean Air Act

- Resource Conservation and Recovery Act

- Toxic Substances Control Act

- Occupational Safety and Health Act

8. How do you stay up-to-date on the latest advancements in pulp grinding and blending technology?

To stay up-to-date on the latest advancements in pulp grinding and blending technology, I would:

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Network with other professionals in the field

- Research new technologies and equipment

- Participate in continuing education programs

9. Describe a challenging situation you faced as a Pulp Grinder and Blender and how you resolved it?

One challenging situation I faced was when a pulp grinder malfunctioned and caused a production shutdown. I quickly identified the problem, replaced the damaged part, and restarted the grinder within a few hours, minimizing downtime and production losses.

10. Why are you interested in working as a Pulp Grinder and Blender in our company?

I am interested in working as a Pulp Grinder and Blender in your company because I am passionate about the paper industry and have a strong track record of success in this field. I am confident that I have the skills and experience to make a significant contribution to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Grinder and Blender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Grinder and Blender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp Grinders and Blenders play a vital role in the paper manufacturing industry, responsible for preparing and processing paper pulp. Their duties encompass:

1. Pulp Grinding

Operate pulp grinders to reduce wood chips into pulp, controlling particle size and consistency to meet specific product specifications.

- Monitor and adjust grinding processes to ensure optimal pulp quality

- Inspect and maintain grinding equipment to prevent breakdowns and ensure efficient operation

2. Pulp Blending

Blend different types of pulp to achieve desired properties such as strength, brightness, and printability

- Control the proportions of different pulp grades based on product specifications

- Monitor blending processes and make adjustments to optimize pulp quality

3. Pulp Quality Control

Conduct routine testing on pulp samples to ensure adherence to quality standards

- Measure pulp properties such as freeness, brightness, and tear strength

- Identify and resolve any issues that affect pulp quality

4. Equipment Maintenance

Perform basic maintenance on pulp grinding and blending equipment

- Clean and lubricate machinery

- Inspect and replace worn or damaged parts

Interview Tips

Preparing for a Pulp Grinder and Blender interview requires a combination of technical knowledge and soft skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Learn about the company’s history, products, and industry trends. This demonstrates your interest and eagerness to contribute.

- Visit the company’s website and social media pages

- Read industry news and articles to stay updated on current best practices

2. Practice Answering Common Interview Questions

Familiarize yourself with common interview questions and prepare concise and well-structured answers. Anticipate questions related to:

- Your experience in pulp grinding and blending

- Your knowledge of pulp quality control techniques

- Your ability to work independently and as part of a team

3. Highlight Your Relevant Skills and Experience

Emphasize your technical skills in pulp grinding and blending, including your expertise in operating and maintaining equipment. Quantify your achievements with specific examples.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences

- Prepare examples of how you improved pulp quality or reduced production costs

4. Be Prepared for Technical Questions

Expect questions that test your understanding of pulp grinding and blending processes. Be prepared to discuss topics such as:

- Types of pulp grinders and their advantages/disadvantages

- Factors affecting pulp quality

- Quality control techniques for pulp

5. Show Your Interest and Enthusiasm

Throughout the interview, express your passion for the paper manufacturing industry and your desire to contribute to the company’s success.

- Ask thoughtful questions about the company and the position

- Convey your willingness to learn and grow within the organization

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pulp Grinder and Blender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pulp Grinder and Blender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.