Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pulp Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

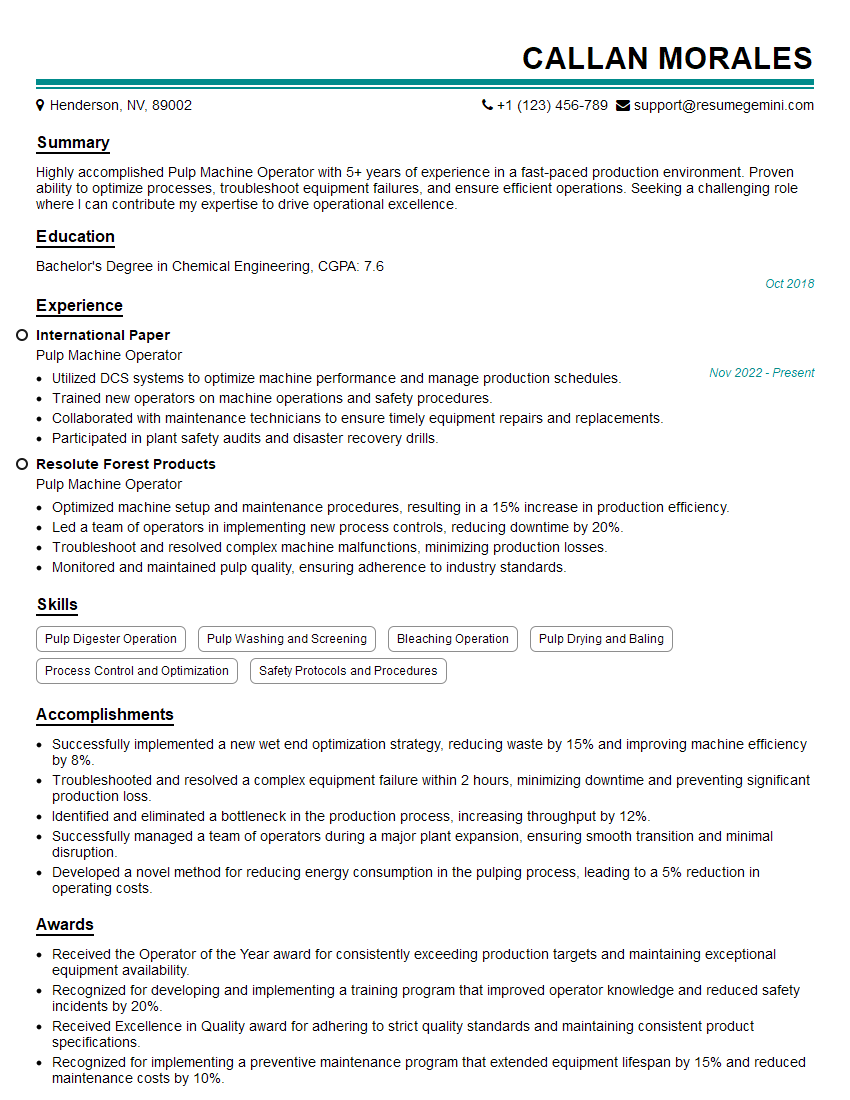

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Machine Operator

1. Describe the key responsibilities of a Pulp Machine Operator.

As a Pulp Machine Operator, I am responsible for:

- Operating and monitoring pulp machines to produce pulp for paper production.

- Monitoring and adjusting machine settings to ensure optimal performance and product quality.

- Maintaining and troubleshooting equipment to prevent breakdowns and ensure efficient operation.

- Following quality control procedures to ensure pulp meets specifications.

- Communicating with other team members to coordinate production and resolve issues.

2. Explain the different types of pulp machines and their applications.

Batch digesters

- Used for producing high-quality pulp for specialty papers.

- Involve cooking wood chips in a chemical solution under pressure.

Continuous digesters

- Used for producing large volumes of pulp for paperboard and newsprint.

- Wood chips are cooked as they move through a series of vessels.

3. Describe the process of pulp washing and screening.

After cooking, the pulp is washed and screened to remove impurities and prepare it for papermaking:

- Washing: Removes chemicals and lignin from the pulp using water.

- Screening: Separates fibers from knots, shives, and other contaminants using screens.

4. How do you ensure the quality of pulp produced?

I ensure pulp quality by:

- Monitoring process parameters, such as temperature, pH, and flow rates.

- Conducting regular quality checks on pulp properties, such as fiber length, brightness, and tensile strength.

- Following established quality control standards.

- Working with the quality control department to identify and resolve quality issues.

5. Describe the safety precautions to be taken when operating a pulp machine.

Safety is paramount when operating a pulp machine. I adhere to strict safety protocols, including:

- Wearing appropriate personal protective equipment, such as gloves, goggles, and earplugs.

- Following lockout-tagout procedures when performing maintenance or repairs.

- Being aware of potential hazards, such as moving parts, high temperatures, and chemicals.

- Responding promptly to emergencies and reporting any unsafe conditions.

6. How do you troubleshoot common issues that may arise during pulp production?

I use a systematic approach to troubleshoot common issues, including:

- Identifying the problem and its potential causes.

- Checking machine settings, process parameters, and equipment.

- Consulting with experienced colleagues or maintenance personnel.

- Implementing corrective actions and monitoring their effectiveness.

7. Explain the importance of teamwork in pulp production.

Teamwork is crucial in pulp production. I work closely with:

- Maintenance technicians: To ensure equipment is functioning properly.

- Quality control personnel: To monitor and maintain pulp quality.

- Other operators: To coordinate production and resolve issues.

8. How do you stay updated on the latest trends and technologies in pulp production?

I stay informed by:

- Reading industry publications and attending conferences.

- Participating in training and development programs.

- Networking with other pulp machine operators and professionals.

9. Describe a situation where you successfully resolved a complex issue in pulp production.

In a previous role, I encountered an issue with the pulp consistency, which affected the quality of the final product. I analyzed the situation, checked equipment settings, and consulted with the maintenance team. I identified a faulty sensor that was providing inaccurate readings. By replacing the sensor and recalibrating the system, I resolved the issue and maintained product quality.

10. Why are you interested in working as a Pulp Machine Operator at our company?

I am eager to join your company because I am impressed by your commitment to sustainability and innovation in pulp production. I am confident that my skills and experience would be a valuable asset to your team, and I am excited about the opportunity to contribute to your success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pulp Machine Operator plays a crucial role in a paper or pulp production facility. Their primary responsibilities include:

1. Machine Operation and Monitoring

Operate and monitor the pulp machine, ensuring efficient and continuous production. Adjust machine settings to optimize output quality and quantity.

- Control pulp flow rate, chemical composition, and temperature.

- Monitor equipment sensors and dashboards for any anomalies or errors.

2. Pulp Quality Control

Conduct regular quality checks on pulp samples to ensure the production of pulp that meets specifications. Identify and promptly address any deviations.

- Perform tests such as freeness, consistency, and brightness analysis.

- Adjust machine parameters and process variables to rectify quality issues.

3. Machine Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting tasks to keep the pulp machine operational. Identify and resolve minor issues independently.

- Inspect and clean equipment, including pumps, screens, and filters.

- Troubleshoot and repair electrical or mechanical malfunctions.

4. Safety and Environmental Compliance

Adhere to established safety protocols and environmental regulations. Ensure the safe operation of equipment and the proper disposal of waste.

- Follow lockout/tagout procedures during machine maintenance.

- Monitor emission levels and implement measures to reduce environmental impact.

Interview Tips

To ace an interview for a Pulp Machine Operator position, candidates should prepare thoroughly and demonstrate their knowledge and skills.

1. Research the Company and Position

Familiarize yourself with the company’s background, operations, and values. Research the specific pulp machine operator role to understand the expected responsibilities.

- Visit the company website and LinkedIn profile.

- Review job descriptions and industry articles.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience in operating and maintaining pulp machinery. Showcase your expertise in pulp quality control and troubleshooting.

- Quantify your accomplishments with specific metrics or examples.

- Use keywords from the job description to demonstrate your alignment.

3. Practice Answering Common Interview Questions

Prepare for typical interview questions such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?”

- Prepare concise and structured responses that highlight your qualifications.

- Practice your delivery and body language to convey confidence and professionalism.

4. Ask Insightful Questions

Prepare thoughtful questions to show your interest and engagement in the role. This demonstrates your curiosity and enthusiasm for the industry.

- Inquire about the company’s growth plans or sustainability initiatives.

- Ask about specific challenges faced in the pulp production process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pulp Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.