Are you gearing up for a career in Pulp Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pulp Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

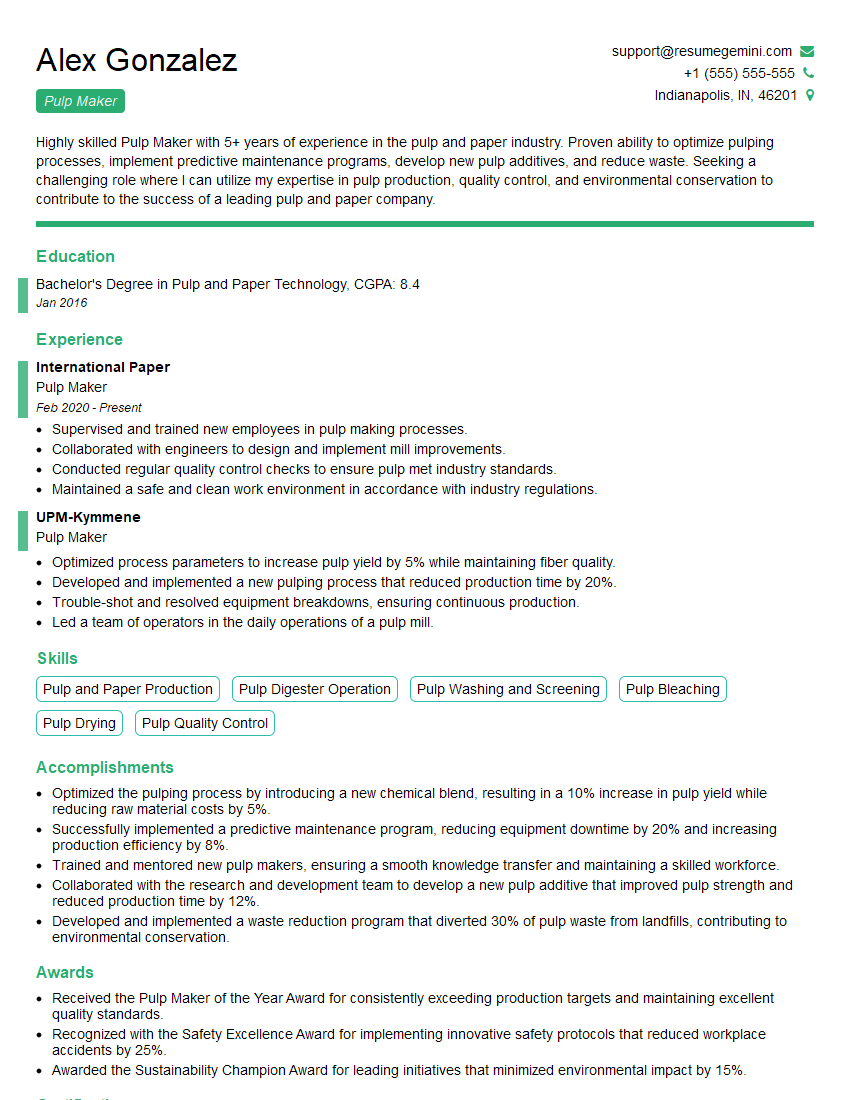

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Maker

1. What are the key steps involved in the pulp making process?

The key steps involved in the pulp making process are:

- Raw material preparation: This involves preparing the raw material, such as wood chips, for the pulping process. This may include debarking, chipping, and screening the raw material.

- Pulping: This is the process of separating the cellulose fibers from the other components of the raw material. This can be done using mechanical, chemical, or a combination of both methods.

- Screening and cleaning: This involves removing impurities from the pulp, such as knots, shives, and dirt.

- Bleaching: This involves removing the lignin from the pulp, which makes the pulp whiter and brighter.

- Drying: This involves removing the water from the pulp to produce a dry sheet of paper or paperboard.

2. Explain the difference between mechanical pulping and chemical pulping.

Mechanical pulping

- Advantages: Mechanical pulping is a relatively inexpensive process that produces a high yield of pulp. The pulp is strong and has good opacity.

- Disadvantages: Mechanical pulping produces a pulp that is not as bright or white as chemical pulp. The pulp also has a shorter fiber length, which makes it weaker than chemical pulp.

Chemical pulping

- Advantages: Chemical pulping produces a pulp that is brighter and whiter than mechanical pulp. The pulp also has a longer fiber length, which makes it stronger than mechanical pulp.

- Disadvantages: Chemical pulping is a more expensive process than mechanical pulping and produces a lower yield of pulp.

3. What are the different types of chemical pulping processes?

- Kraft process: This is the most common chemical pulping process. It uses a mixture of sodium hydroxide and sodium sulfide to dissolve the lignin in the wood.

- Sulfite process: This process uses a mixture of sulfurous acid and sodium sulfite to dissolve the lignin in the wood.

- Soda process: This process uses sodium hydroxide to dissolve the lignin in the wood.

4. What are the key factors that affect the quality of the pulp?

- Raw material: The quality of the raw material will have a significant impact on the quality of the pulp.

- Pulping process: The pulping process can affect the brightness, strength, and yield of the pulp.

- Bleaching process: The bleaching process can affect the brightness and whiteness of the pulp.

5. What are the different grades of pulp?

- Newsprint grade: This is a low-quality pulp that is used to make newsprint.

- Printing and writing grade: This is a medium-quality pulp that is used to make printing and writing paper.

- Tissue grade: This is a high-quality pulp that is used to make tissue paper.

6. What are the environmental considerations associated with the pulp making process?

- Water pollution: The pulp making process can generate wastewater that contains pollutants such as lignin, suspended solids, and dissolved organic matter.

- Air pollution: The pulp making process can generate air pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter.

- Solid waste: The pulp making process can generate solid waste such as bark, wood chips, and sludge.

7. What are the key trends in the pulp and paper industry?

- Increasing demand for sustainable products: Consumers are increasingly demanding products that are made from sustainable materials.

- Growing use of recycled fibers: The use of recycled fibers in the pulp and paper industry is growing due to the environmental benefits.

- Development of new technologies: New technologies are being developed to improve the efficiency and productivity of the pulp and paper industry.

8. What are the challenges facing the pulp and paper industry?

- Competition from other materials: The pulp and paper industry is facing competition from other materials such as plastics and metals.

- Fluctuating prices for raw materials: The prices of raw materials such as wood and chemicals can fluctuate significantly, which can impact the profitability of the pulp and paper industry.

- Environmental regulations: The pulp and paper industry is subject to environmental regulations that can increase the cost of production.

9. What are the opportunities for the pulp and paper industry?

- Growing demand for sustainable products: The demand for sustainable products is growing, which creates opportunities for the pulp and paper industry to develop and market sustainable products.

- Development of new technologies: New technologies are being developed that can improve the efficiency and productivity of the pulp and paper industry.

- Expansion into new markets: The pulp and paper industry has the opportunity to expand into new markets such as the developing world.

10. What are your strengths and weaknesses as a pulp maker?

My strengths as a pulp maker include:

- Technical expertise: I have a strong understanding of the pulp making process and the different factors that affect the quality of the pulp.

- Experience: I have several years of experience working in the pulp and paper industry.

- Problem-solving skills: I am able to quickly identify and solve problems that arise during the pulp making process.

My weaknesses as a pulp maker include:

- Limited knowledge of other areas of the pulp and paper industry: I am not as familiar with other areas of the pulp and paper industry, such as papermaking and converting.

- Lack of management experience: I have not held any management positions in the pulp and paper industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp Makers are responsible for overseeing the production of pulp, a vital ingredient in the manufacture of paper and other paper products. They ensure that the pulp meets the required quality standards and is produced efficiently and cost-effectively.

1. Pulp Production

Pulp Makers are responsible for overseeing the entire pulp production process, from the preparation of raw materials to the final drying and baling of the pulp. They must have a thorough understanding of the various pulping processes, including mechanical pulping, chemical pulping, and semi-chemical pulping.

- Monitor and control the pulping process to ensure that the pulp meets the desired quality specifications.

- Adjust process parameters, such as temperature, pressure, and chemical concentrations, to optimize pulp quality and yield.

2. Quality Control

Pulp Makers are responsible for ensuring that the pulp meets the required quality standards. They must be able to identify and correct any defects in the pulp, such as contamination, color variations, and fiber length.

- Conduct regular quality checks on the pulp to ensure that it meets the desired specifications.

- Identify and correct any defects in the pulp, such as contamination, color variations, and fiber length.

3. Process Optimization

Pulp Makers are constantly looking for ways to improve the efficiency and cost-effectiveness of the pulping process. They may work with engineers and other plant personnel to identify and implement process improvements.

- Analyze production data to identify areas for improvement in the pulping process.

- Work with engineers and other plant personnel to implement process improvements that increase efficiency and reduce costs.

4. Safety and Environmental Compliance

Pulp Makers must follow all safety and environmental regulations. They must be aware of the hazards associated with the pulping process and take steps to minimize risks to workers and the environment.

- Follow all safety and environmental regulations.

- Identify and mitigate hazards associated with the pulping process.

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you to tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, products, and services.

- Read news articles and press releases about the company to get a sense of their recent developments and initiatives.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic about the position and the company. Be sure to convey your enthusiasm during your interview. This will show the interviewer that you are genuinely interested in the job and that you would be a valuable asset to the team.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in learning more about the opportunity and that you are serious about the job.

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pulp Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!