Are you gearing up for an interview for a Pulp Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pulp Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

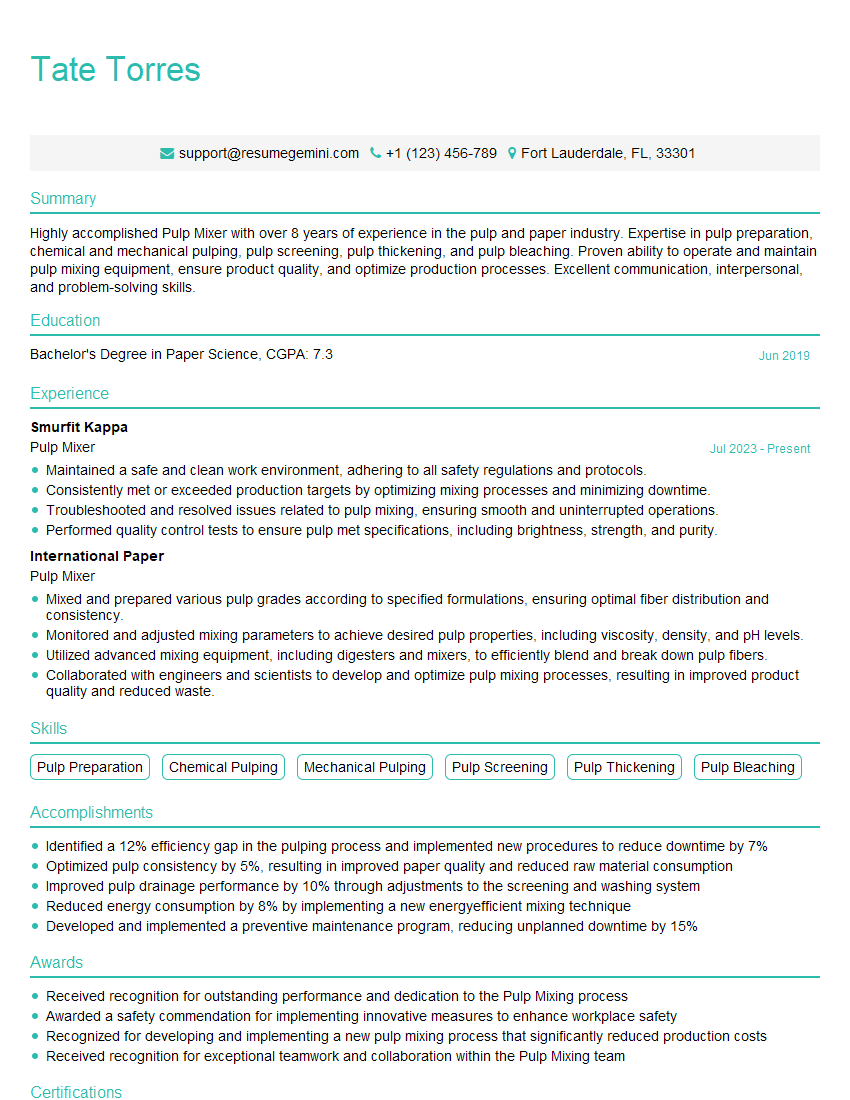

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Mixer

1. Can you explain the process of preparing pulp for paper production?

The process of preparing pulp for paper production involves several steps:

- Pulping: The raw materials (wood, other plant fibers) are broken down into a slurry of fibers using mechanical or chemical processes.

- Screening: The pulp is screened to remove any impurities, such as dirt, sand, and wood chips.

- Bleaching: The pulp is bleached to remove lignin and brighten the fibers, improving paper quality.

- Washing and thickening: The pulp is washed to remove any remaining chemicals and thickened to prepare it for papermaking.

2. What are the different types of pulp used in paper production?

- Mechanical pulp: Made from wood chips and produces paper with high strength but lower brightness.

- Chemical pulp: Made from wood chips treated with chemicals to remove lignin, resulting in paper with high brightness and softness.

- Recycled pulp: Made from waste paper, used to create recycled paper products.

3. How do you optimize the pH levels in the pulp mixture to achieve desired paper properties?

Optimizing pH levels in the pulp mixture is crucial:

- Paper strength: Higher pH levels (more alkaline) can weaken paper.

- Brightness: Higher pH levels can improve brightness but at the expense of strength.

- Chemical reactions: pH levels affect chemical reactions during the papermaking process.

- Equipment corrosion: Highly acidic or alkaline pH levels can corrode equipment.

By carefully adjusting pH levels, I ensure optimal paper properties and minimize equipment damage.

4. What are the common quality control measures implemented in pulp mixing?

- Freeness testing: Measures the pulp’s drainage rate, which affects paper porosity and strength.

- Brightness measurement: Determines the pulp’s whiteness.

- Viscosity testing: Assesses the pulp’s consistency and flowability.

- Residual chemical analysis: Monitors chemical levels to prevent contamination.

- Fiber analysis: Examines the fiber length and distribution to ensure proper paper formation.

5. Describe the role of additives in pulp mixing and their impact on paper quality.

Additives play a vital role in pulp mixing, enhancing paper properties:

- Fillers: Add bulk and opacity, reducing ink absorption.

- Binders: Strengthen paper and improve surface finish.

- Sizing agents: Increase water resistance.

- Colorants: Add color to the paper.

- Optical brighteners: Enhance brightness and compensate for aging.

By carefully selecting and using additives, I optimize paper quality for specific applications.

6. How do you troubleshoot common problems encountered during pulp mixing?

Common problems and troubleshooting strategies:

- Poor drainage: Adjust pH levels, check for papermaking additive overdosing.

- Weak paper: Check pulp freeness, adjust additives, and optimize pH levels.

- Uneven paper surface: Examine pulp consistency and fiber distribution.

- Contamination: Identify the source of contamination and implement corrective measures.

- Equipment malfunctions: Check equipment for wear and tear, perform routine maintenance.

7. How do you maintain a safe and efficient work environment in the pulp mixing area?

- Follow safety protocols: Wear protective gear, follow chemical handling guidelines.

- Maintain equipment: Regularly inspect and maintain machinery to prevent accidents.

- Control dust and fumes: Use ventilation systems and respiratory protection.

- Proper waste disposal: Dispose of chemicals and waste materials according to regulations.

- Train staff: Educate employees on safety procedures and emergency response plans.

8. How do you collaborate with other departments, such as production and quality control, to ensure smooth operations?

I foster collaboration through:

- Regular communication: Attend meetings, share updates, and discuss issues.

- Clear documentation: Maintain records and share information to ensure transparency.

- Joint problem-solving: Work with other teams to address challenges collectively.

- Continuous improvement: Participate in ongoing efforts to optimize processes and improve quality.

9. What are your goals and aspirations as a Pulp Mixer?

My goals as a Pulp Mixer are to:

- Master the art of pulp mixing and contribute to producing high-quality paper.

- Develop expertise in quality control measures and troubleshooting to maintain optimal operations.

- Collaborate effectively with other departments and contribute to a seamless production process.

- Stay up-to-date with industry advancements and best practices to enhance my skills and knowledge.

10. How do you stay informed about emerging trends and technologies in pulp mixing?

- Attend industry conferences and workshops: Engage with experts and learn about latest developments.

- Read trade publications and technical journals: Stay abreast of research and innovation.

- Network with professionals: Connect with peers to exchange ideas and knowledge.

- Seek opportunities for professional development: Participate in training programs and certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pulp Mixer is responsible for overseeing the mixing of pulp, paper, or other materials in a manufacturing environment. The primary objective of this role is to ensure the production of high-quality and consistent products while maintaining safety and efficiency.

1. Pulp Mixing and Blending

- Operate and maintain pulp mixing equipment, such as mixers, blenders, and beaters

- Determine the correct proportions and sequence of ingredients to achieve desired pulp characteristics

- Monitor and adjust mixing parameters, such as temperature, pH, and viscosity, to ensure optimal results

2. Quality Control and Testing

- Perform quality control tests on pulp samples to evaluate consistency, strength, and other properties

- Identify and resolve any deviations from established specifications

- Maintain records of quality control data and report any issues to supervisors

3. Equipment Maintenance and Troubleshooting

- Perform routine maintenance and cleaning of mixing equipment to ensure proper operation

- Identify and troubleshoot mechanical or electrical problems with mixing equipment

- Order and install replacement parts as needed

4. Safety and Environmental Compliance

- Adhere to all safety protocols and regulations related to the operation of mixing equipment

- Maintain a clean and organized work area

- Follow environmental guidelines for the handling and disposal of pulp and chemicals

Interview Tips

Preparing for a Pulp Mixer interview requires both technical knowledge and an understanding of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Role

- Familiarize yourself with the company’s history, products, and values.

- Thoroughly review the job description and identify the key responsibilities and qualifications.

2. Highlight Your Technical Skills

- Showcase your knowledge of pulp mixing processes, quality control techniques, and equipment maintenance.

- Provide specific examples of your experience in these areas and quantify your results whenever possible.

3. Emphasize Your Safety and Compliance Awareness

- Demonstrate your understanding of safety protocols and environmental regulations in the industry.

- Highlight your commitment to maintaining a safe and compliant work environment.

4. Prepare for Common Interview Questions

- Be prepared to discuss your experience with specific pulp mixing equipment and techniques.

- Practice answering questions related to quality control, troubleshooting, and teamwork.

5. Ask Thoughtful Questions

- Asking insightful questions shows your interest in the role and the company.

- Prepare questions related to the company’s goals, industry trends, or the specific responsibilities of the Pulp Mixer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pulp Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!